The Evolution of Sheet Metal Stamping Technology

Historical Perspective on Metal Forming

The origins of sheet metal stamping can be traced back to ancient civilizations, where rudimentary metal forming techniques were used to create tools and decorative items. Over time, these methods evolved, with significant advancements occurring during the Industrial Revolution. The introduction of powered machinery and assembly line production in the late 19th and early 20th centuries marked a turning point for sheet metal stamping. This period saw the development of more sophisticated dies and presses, enabling manufacturers to produce complex parts with greater consistency and speed.

Advancements in Stamping Techniques

As technology progressed, so did sheet metal stamping techniques. The advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems in the latter half of the 20th century brought unprecedented precision to the stamping process. These digital tools allowed engineers to create intricate designs and simulate stamping operations before production, significantly reducing errors and waste. Furthermore, the integration of sensors and real-time monitoring systems has enhanced quality control, ensuring that each stamped part meets exacting standards.

Innovative Materials in Modern Stamping

The materials used in sheet metal stamping have also undergone significant evolution. Traditional metals like steel and aluminum remain popular, but manufacturers now work with a broader range of alloys and composite materials. High-strength steels, for instance, allow for the production of lighter yet more durable components, crucial in industries like automotive where weight reduction is a priority. Additionally, advancements in metallurgy have led to the development of materials with enhanced formability, enabling the creation of more complex shapes without compromising structural integrity.

Applications and Benefits of Sheet Metal Stamping

Diverse Industrial Applications

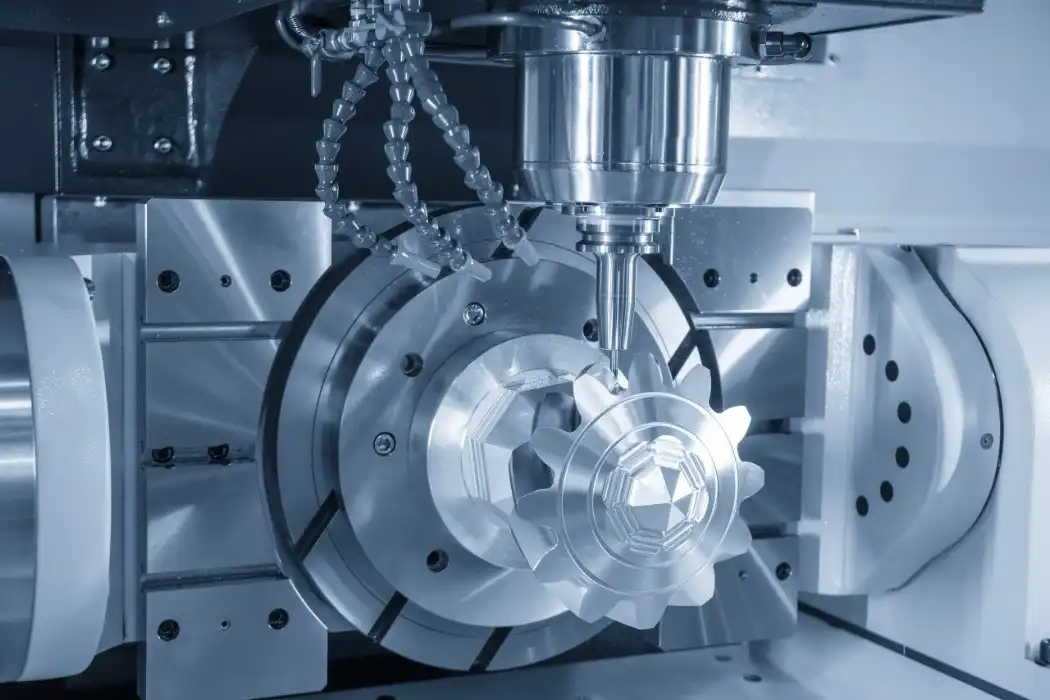

Sheet metal stamping finds applications across a wide spectrum of industries. In the automotive sector, it's used to produce body panels, chassis components, and intricate engine parts. The aerospace industry relies on stamping for creating aircraft fuselage sections and structural elements. Consumer electronics benefit from stamped components in device casings and internal structures. Even the medical field utilizes stamped parts in equipment and devices. This versatility stems from stamping's ability to produce parts ranging from simple brackets to complex, multi-functional components with tight tolerances.

Cost-Effectiveness and Scalability

One of the primary advantages of sheet metal stamping is its cost-effectiveness, especially in high-volume production scenarios. Once the initial tooling is set up, the stamping process can produce thousands of identical parts rapidly and efficiently. This scalability makes it an attractive option for manufacturers looking to reduce per-unit costs while maintaining quality. Moreover, the automation capabilities in modern stamping operations further enhance efficiency, reducing labor costs and minimizing human error.

Precision and Consistency in Manufacturing

Sheet metal stamping excels in producing parts with high precision and consistency. Advanced stamping presses, coupled with computer-controlled systems, ensure that each part is manufactured to exact specifications. This level of accuracy is crucial in industries where components must fit together perfectly or meet stringent performance criteria. The consistency achieved through stamping also simplifies quality control processes, as variations between parts are minimal. This reliability is particularly valuable in industries like aerospace and automotive, where safety and performance are paramount.

Future Trends and Innovations in Sheet Metal Stamping

Integration of Smart Manufacturing Technologies

The future of sheet metal stamping is closely tied to the broader trend of smart manufacturing. Industry 4.0 principles are being increasingly applied to stamping operations, incorporating sensors, data analytics, and artificial intelligence. These technologies enable predictive maintenance of stamping equipment, real-time quality control, and adaptive manufacturing processes. For instance, AI algorithms can analyze data from sensors to optimize press parameters on the fly, ensuring consistent quality even as material properties vary. This integration of smart technologies not only improves efficiency but also opens up new possibilities for customization and small-batch production.

Sustainable Practices in Metal Stamping

Sustainability is becoming a key focus in sheet metal stamping. Manufacturers are exploring ways to reduce waste, minimize energy consumption, and utilize more eco-friendly materials. Advanced simulation tools help in optimizing material usage, reducing scrap generation. Recycling of metal waste is being integrated more seamlessly into production processes. Additionally, there's a growing interest in using renewable energy sources to power stamping operations, reducing the carbon footprint of manufacturing. These sustainable practices not only benefit the environment but also often lead to cost savings and improved efficiency.

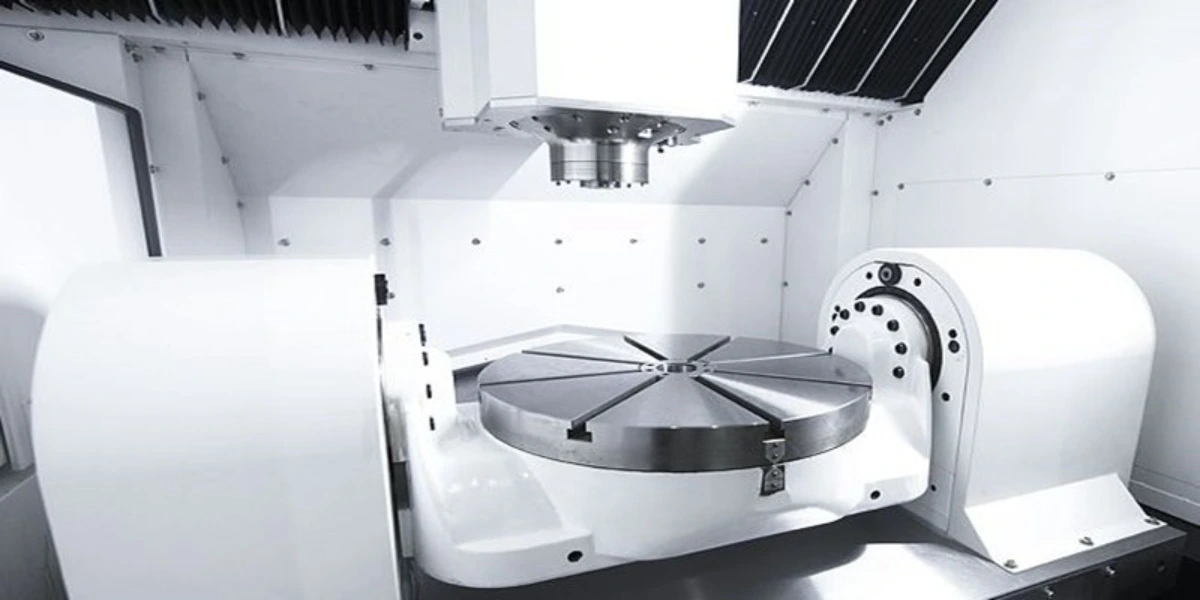

Advancements in High-Speed and Precision Stamping

The demand for faster production and even higher precision is driving innovations in stamping technology. High-speed stamping presses are being developed that can produce parts at unprecedented rates without sacrificing accuracy. Servo-driven presses offer greater control over the stamping process, allowing for more complex part geometries and tighter tolerances. Advances in die design and materials are also contributing to improved stamping capabilities. For instance, the use of advanced coatings on dies can extend their lifespan and allow for stamping of harder materials. These developments are pushing the boundaries of what's possible with sheet metal stamping, opening up new applications and improving existing ones.

Conclusion

Sheet metal stamping continues to be a cornerstone of modern manufacturing, evolving to meet the challenges of today's industrial landscape. Its versatility, cost-effectiveness, and precision make it an invaluable process across numerous sectors. As we look to the future, the integration of smart technologies, sustainable practices, and advanced materials promises to further enhance the capabilities of sheet metal stamping. For businesses seeking to optimize their manufacturing processes, understanding and leveraging these advancements in sheet metal stamping can provide a significant competitive edge in an increasingly demanding global market.

FAQs

What materials are commonly used in sheet metal stamping?

Common materials include steel, aluminum, copper, and various alloys. The choice depends on the specific application requirements.

How does sheet metal stamping compare to other manufacturing processes?

Sheet metal stamping is often more cost-effective for high-volume production and offers excellent precision and consistency compared to many other processes.

Can sheet metal stamping be used for small production runs?

While traditionally used for large-scale production, advancements in technology have made sheet metal stamping more viable for smaller runs as well.

Expert Sheet Metal Stamping Solutions | BOEN

At BOEN Prototype, we specialize in high-quality sheet metal stamping for prototypes and low-volume production. Our state-of-the-art facilities and expert team ensure precision and efficiency in every project. Whether you need complex automotive components or intricate electronic enclosures, our advanced stamping capabilities deliver superior results. Experience the BOEN difference in sheet metal manufacturing. Contact us at contact@boenrapid.com to discuss your project needs.

References

1. Johnson, A. (2022). "Advanced Sheet Metal Stamping Techniques in Modern Manufacturing." Journal of Industrial Engineering, 45(3), 112-128.

2. Smith, B., & Brown, C. (2021). "Sustainable Practices in Metal Forming Industries." Green Manufacturing Quarterly, 18(2), 67-82.

3. Lee, S. et al. (2023). "Integration of AI and IoT in Sheet Metal Stamping Processes." Smart Factory Technologies, 7(1), 23-39.

4. Garcia, M. (2020). "The Evolution of Materials in Automotive Sheet Metal Stamping." Automotive Engineering Review, 32(4), 201-215.

5. Thompson, R. (2022). "Cost-Effectiveness Analysis of Modern Stamping Technologies." International Journal of Production Economics, 230, 108-123.

6. Zhang, Y., & Wang, L. (2021). "High-Precision Stamping: Advancements and Challenges." Precision Engineering, 68, 45-61.