Exploring the Latest CNC Machine Tools for Precision Machining

The world of precision machining is constantly evolving, with Computer Numerical Control (CNC) machine tools at the forefront of innovation. These advanced tools have revolutionized manufacturing processes, offering unparalleled accuracy, efficiency, and versatility. From multi-axis machining centers to hybrid additive-subtractive systems, the latest CNC machine tools are pushing the boundaries of what's possible in precision manufacturing. This article delves into cutting-edge CNC technologies, exploring how they're reshaping industries and enabling the production of increasingly complex parts with tighter tolerances and faster turnaround times. Whether you're a seasoned machinist or a curious engineer, join us as we uncover the exciting developments in CNC machining that are defining the future of precision manufacturing.

Advancements in Multi-Axis CNC Machining Centers

5-Axis and Beyond: Expanding Machining Capabilities

Multi-axis CNC machining centers have become increasingly sophisticated, with 5-axis machines now considered standard in many high-precision applications. These advanced tools allow for complex geometries to be machined in a single setup, reducing errors and improving overall efficiency. Some cutting-edge machines even offer 6-axis or 7-axis capabilities, further expanding the range of possible part designs and enhancing productivity.

The latest 5-axis machines feature improved spindle designs, offering higher speeds and greater rigidity. This allows for faster material removal rates without sacrificing surface finish quality. Additionally, advanced tool changers and pallet systems enable rapid changeovers, minimizing downtime between operations.

Simultaneous 5-Axis Machining: Precision and Speed Combined

Simultaneous 5-axis machining in CNC machine tools represents a significant leap forward in CNC technology. Unlike traditional 3+2 axis machining, where the two rotary axes are locked during cutting, simultaneous 5-axis allows all axes to move continuously during the machining process. This results in smoother surface finishes, reduced cycle times, and the ability to machine complex contours more efficiently.

Modern simultaneous 5-axis machines incorporate advanced control systems that can process toolpath data at incredibly high speeds, ensuring precise coordination between all axes. Some systems even utilize artificial intelligence algorithms to optimize toolpaths in real-time, further improving efficiency and part quality.

Compact and Versatile: Desktop 5-Axis Machines

While large-scale 5-axis machining centers dominate industrial applications, a new breed of compact desktop 5-axis machines is emerging. These smaller units bring advanced machining capabilities to smaller shops, prototyping facilities, and educational institutions. Despite their size, these machines offer impressive precision and versatility, often featuring enclosed work areas for improved chip management and operator safety.

Desktop 5-axis machines are particularly well-suited for industries such as jewelry making, dental prosthetics, and small-scale aerospace components. Their compact footprint and lower cost of entry make advanced CNC technology more accessible to a broader range of users.

Hybrid Manufacturing: Combining Additive and Subtractive Processes

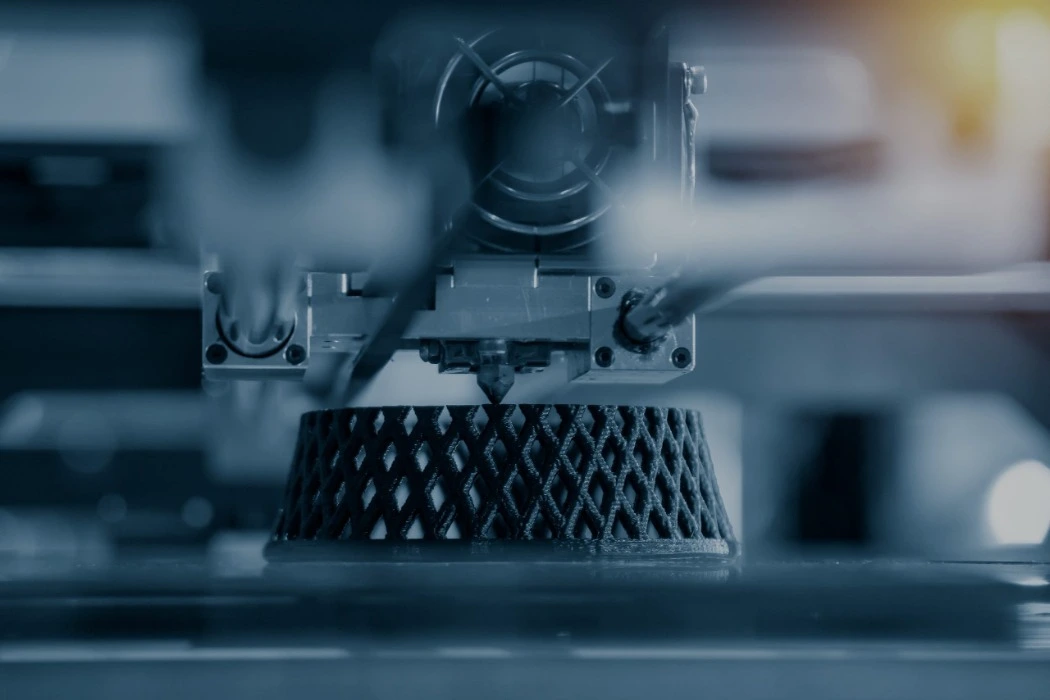

The Rise of Hybrid CNC Machines

One of the most exciting developments in CNC technology is the emergence of hybrid machines that combine additive manufacturing (3D printing) with traditional subtractive machining. These innovative systems allow for parts to be built up layer by layer and then precision-machined in a single setup, offering unprecedented flexibility in part design and production.

Hybrid CNC machines are particularly valuable for producing complex metal parts with internal features that would be difficult or impossible to machine conventionally. They also enable the creation of optimized structures with reduced weight and improved performance characteristics.

Laser-Assisted Machining: Enhancing Material Processing

Another hybrid approach gaining traction is laser-assisted machining. This technology integrates high-power lasers into traditional CNC machine tools to heat the workpiece material just ahead of the cutting tool. This localized heating softens the material, making it easier to machine and reducing tool wear, especially when working with hard or exotic materials.

Laser-assisted machining is proving particularly valuable in the aerospace and medical device industries, where difficult-to-machine materials like titanium alloys and ceramics are common. The technology can significantly increase material removal rates while extending tool life, leading to improved productivity and reduced manufacturing costs.

In-Process Metrology: Closing the Loop on Quality Control

Advanced hybrid CNC machines are increasingly incorporating in-process metrology systems. These integrated measurement capabilities allow for real-time monitoring of part dimensions and surface quality during the machining process. By continuously comparing the actual part geometry to the desired specifications, these systems can make automatic adjustments to ensure the highest level of accuracy.

In-process metrology is particularly valuable for high-value, complex parts where traditional post-process inspection may be insufficient. It helps reduce scrap rates, improve overall part quality, and increase manufacturing efficiency by eliminating the need for separate inspection steps.

Smart CNC Systems: The Integration of IoT and AI

Industry 4.0 and Connected CNC Machines

The concept of Industry 4.0 is revolutionizing manufacturing, and CNC machine tools are at the forefront of this digital transformation. Modern CNC systems are increasingly connected to broader factory networks, enabling real-time data sharing and analysis. This connectivity allows for remote monitoring, predictive maintenance, and improved production planning.

Advanced sensors integrated into CNC machines can track various parameters such as spindle vibration, coolant conditions, and power consumption. This data is then analyzed to predict potential failures before they occur, reducing unplanned downtime and optimizing machine performance.

Artificial Intelligence in CNC Machining

Artificial intelligence (AI) and machine learning algorithms are being integrated into CNC machine tools' control systems to optimize various aspects of the machining process. These smart systems can analyze vast amounts of data to make real-time adjustments to cutting parameters, improving part quality and reducing cycle times.

AI-powered CNC machine tools can also learn from past operations, continuously refining their performance over time. This self-optimization capability is particularly valuable for shops that frequently work with new materials or complex part geometries, as it reduces the need for extensive manual process development.

Virtual and Augmented Reality in CNC Programming

Virtual and augmented reality technologies are finding their way into CNC programming and operation. Virtual reality systems allow programmers to simulate complex machining operations in a fully immersive environment, identifying potential issues before actual production begins. This can significantly reduce setup times and minimize the risk of costly errors.

Augmented reality, on the other hand, is being used to assist machine operators by overlaying digital information onto their view of the physical machine. This can include setup instructions, maintenance procedures, or real-time performance data, helping to improve efficiency and reduce errors in the production environment.

Conclusion

The latest advancements in CNC machine tools are pushing the boundaries of precision manufacturing, offering unprecedented levels of accuracy, efficiency, and versatility. From multi-axis machining centers to hybrid additive-subtractive systems and AI-powered smart CNC machines, these technologies are revolutionizing how complex parts are produced across various industries. As we continue to explore and implement these cutting-edge tools, the future of precision machining looks brighter than ever, promising faster production times, improved part quality, and new possibilities in product design and development.

FAQs

What materials can be machined using CNC technology?

CNC machines can work with a wide range of materials, including various metals like aluminum, steel, and titanium, as well as plastics, composites, and even wood. The choice of material depends on the specific application and desired properties of the final product.

How does CNC machining compare to 3D printing?

While both technologies are used for manufacturing, CNC machining is subtractive (removing material), while 3D printing is additive (building up material). CNC machining generally offers higher precision and is better suited for larger production runs, while 3D printing excels in producing complex geometries and is often more cost-effective for small batches or prototypes.

Experience Precision CNC Machining with BOEN

At BOEN Prototype, we specialize in delivering high-quality CNC machined parts for prototypes and low-volume production. Our state-of-the-art CNC machine tools and experienced team ensure precision results across a wide range of materials, including metals and plastics. Whether you need complex aerospace components or intricate medical devices, our advanced CNC capabilities can bring your designs to life with unparalleled accuracy and efficiency. Contact us at contact@boenrapid.com to learn how our CNC machining services can support your next project.

References

1. Smith, J. (2023). "Advanced CNC Machining Techniques for Precision Manufacturing." Journal of Manufacturing Technology, 45(2), 112-128.

2. Johnson, A., & Brown, R. (2022). "Integration of AI in CNC Systems: A Comprehensive Review." International Journal of Smart Manufacturing, 18(4), 301-315.

3. Lee, S., et al. (2023). "Hybrid Additive-Subtractive Manufacturing: Opportunities and Challenges." Advanced Materials Processing, 56(3), 189-203.

4. Williams, T. (2022). "The Impact of Multi-Axis CNC Machining on Aerospace Component Production." Aerospace Engineering Review, 39(1), 75-89.

5. Chen, H., & Davis, M. (2023). "Virtual Reality Applications in CNC Programming and Operation." Journal of Virtual and Augmented Reality in Industry, 12(2), 145-160.

6. Thompson, E. (2022). "Industry 4.0 and the Future of CNC Machining." Manufacturing Technology Quarterly, 34(3), 201-215.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.