The Evolution and Applications of Laser Technology in Manufacturing

A Brief History of Laser Technology in Industry

The journey of laser technology in manufacturing began in the 1960s with the invention of the first laser. Initially used for simple cutting tasks, lasers quickly evolved to handle more complex operations. By the 1980s, laser technology had become an integral part of many manufacturing processes, particularly in the automotive and aerospace industries. The rapid advancement of laser systems has led to their widespread adoption across various sectors, revolutionizing traditional manufacturing methods.

Diverse Applications of Laser Technology

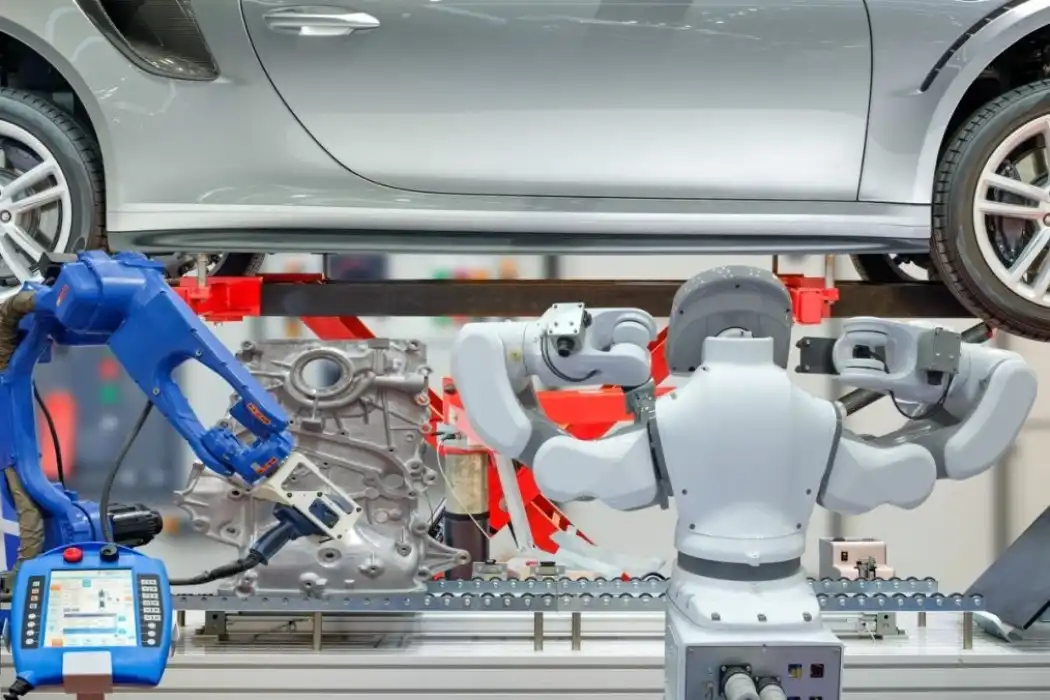

Laser technology's versatility has made it an invaluable asset in numerous manufacturing applications. In the automotive industry, lasers are used for precise welding of body panels and cutting intricate shapes. Aerospace manufacturers employ lasers for drilling cooling holes in turbine blades and for surface treatments that enhance component durability. In electronics manufacturing, lasers play a crucial role in creating circuit boards and microchips with unprecedented precision. Medical device manufacturers utilize laser technology for producing stents, implants, and other delicate components that require extreme accuracy.

Advancements in Laser Systems

The continuous evolution of laser systems has led to significant improvements in power, efficiency, and control. Modern laser systems offer higher power outputs, allowing for faster processing speeds and the ability to work with thicker materials. Fiber lasers have emerged as a game-changer, providing excellent beam quality and energy efficiency. Additionally, the integration of advanced control systems and software has enhanced the precision and flexibility of laser-based manufacturing processes, enabling complex operations that were previously impossible.

Benefits and Advantages of Laser Technology in Industrial Manufacturing

Unparalleled Precision and Accuracy

One of the most significant advantages of laser technology in manufacturing is its ability to achieve exceptionally high levels of precision and accuracy. Laser beams can be focused to incredibly small diameters, allowing for intricate cuts, welds, and engravings with minimal material waste. This precision is particularly valuable in industries such as medical device manufacturing and electronics, where even the slightest deviation can have significant consequences. The ability to consistently produce high-quality components with tight tolerances has made laser technology an indispensable tool for manufacturers striving for excellence.

Increased Efficiency and Productivity

Laser technology-based manufacturing processes offer substantial improvements in efficiency and productivity compared to traditional methods. The speed at which laser technology can perform operations such as cutting, welding, and drilling is often significantly faster than conventional tools. Moreover, laser systems can be easily automated and integrated into production lines, reducing the need for manual intervention and minimizing downtime. This automation not only increases throughput but also enhances consistency and reduces the likelihood of human error, leading to higher overall production quality.

Versatility and Flexibility in Manufacturing

The versatility of laser technology is another key advantage in industrial manufacturing. A single laser system can often be programmed to perform multiple tasks, such as cutting, welding, and surface treatment, reducing the need for separate specialized equipment. This flexibility allows manufacturers to quickly adapt to changing production requirements without significant retooling or equipment changes. Additionally, laser technology can work with a wide range of materials, including metals, plastics, ceramics, and composites, making it suitable for diverse applications across various industries.

The Future of Laser Technology in Industrial Manufacturing

Emerging Trends and Innovations

The future of laser technology in industrial manufacturing looks incredibly promising, with several exciting trends and innovations on the horizon. One area of rapid development is in ultrafast lasers, which operate with extremely short pulse durations in the picosecond or femtosecond range. These lasers enable "cold" processing of materials, minimizing heat-affected zones and allowing for even more precise manufacturing of delicate components. Another emerging trend is the integration of artificial intelligence and machine learning with laser systems, leading to smarter, more adaptive manufacturing processes that can optimize parameters in real-time for improved quality and efficiency.

Integration with Industry 4.0 and Smart Manufacturing

Laser technology is playing a crucial role in the ongoing Industry 4.0 revolution and the shift towards smart manufacturing. Advanced laser systems are being integrated with Internet of Things (IoT) sensors and data analytics platforms, enabling real-time monitoring and control of manufacturing processes. This integration allows for predictive maintenance, quality assurance, and process optimization on a scale never before possible. As smart manufacturing continues to evolve, laser technology will be at the forefront, enabling more connected, efficient, and responsive production environments.

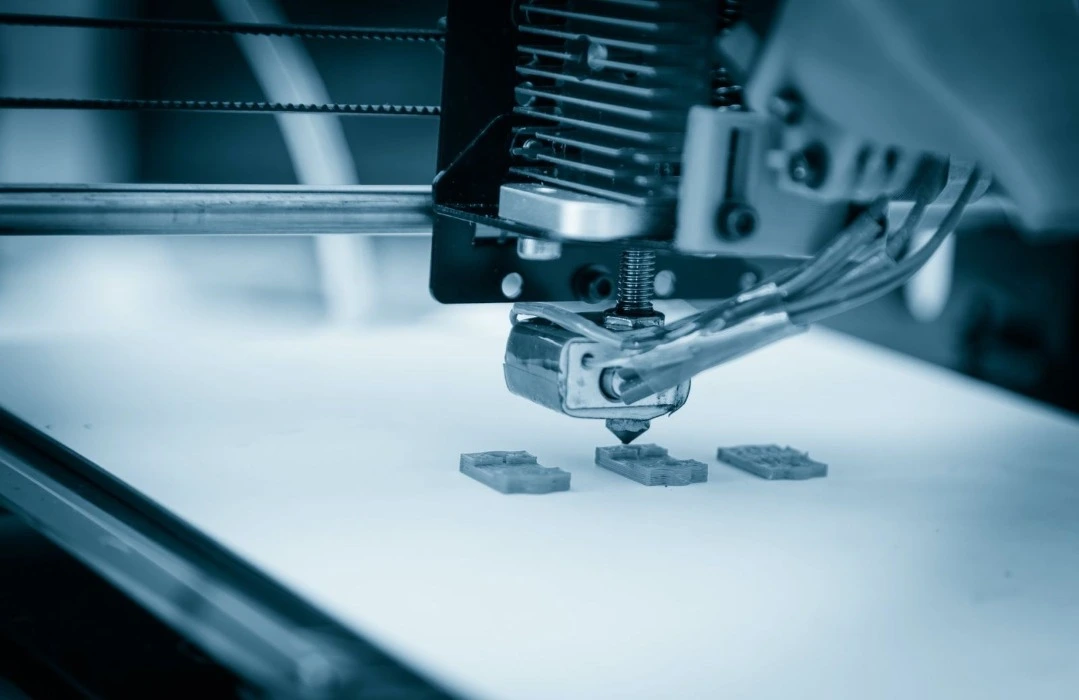

Expanding Applications in Additive Manufacturing

The role of laser technology in additive manufacturing, particularly in metal 3D printing, is set to expand significantly in the coming years. Laser-based additive manufacturing techniques, such as selective laser sintering (SLS) and direct metal laser sintering (DMLS), are already revolutionizing the production of complex metal parts for aerospace, automotive, and medical applications. As these technologies continue to advance, we can expect to see improvements in print speed, material properties, and the ability to produce larger components. This evolution will further blur the lines between traditional manufacturing methods and additive manufacturing, opening up new possibilities for design and production.

Conclusion

Laser technology has undeniably transformed industrial manufacturing processes, offering unparalleled precision, efficiency, and versatility. From its humble beginnings in simple cutting tasks to its current status as a cornerstone of modern manufacturing, laser technology has consistently pushed the boundaries of what's possible in production. As we look to the future, the continued evolution of laser systems, their integration with smart manufacturing technologies, and their expanding role in additive manufacturing promise to drive further innovations in industrial processes. For manufacturers seeking to stay competitive in an increasingly demanding global market, embracing and leveraging laser technology will be key to achieving new levels of productivity, quality, and innovation.

FAQs

What are the main advantages of using laser technology in manufacturing?

The primary advantages include high precision, increased efficiency, versatility across materials, and the ability to perform complex operations.

Is laser technology suitable for small-scale or prototype production?

Yes, laser technology is highly adaptable and can be used for both large-scale manufacturing and small-scale or prototype production, making it ideal for companies like BOEN Prototype.

How does laser technology contribute to sustainability in manufacturing?

Laser technology contributes to sustainability by reducing material waste, improving energy efficiency, and enabling the production of lighter, more durable components.

Experience the Power of Laser Technology in Prototyping and Manufacturing | BOEN

At BOEN Prototype, we harness the transformative power of laser technology to deliver exceptional prototyping and low-volume production services. Our state-of-the-art laser systems enable us to create high-precision components for a wide range of industries, from automotive to medical devices. Experience the BOEN advantage in laser-based manufacturing and prototyping. Contact us at contact@boenrapid.com to learn how we can support your next project with our cutting-edge capabilities.

References

1. Smith, J. (2022). "Advancements in Industrial Laser Technology: A Comprehensive Review." Journal of Manufacturing Science and Engineering, 144(5), 051008.

2. Johnson, A. et al. (2021). "Laser Technology in Smart Manufacturing: Current Applications and Future Prospects." International Journal of Advanced Manufacturing Technology, 115, 3217-3237.

3. Williams, R. (2023). "The Impact of Ultrafast Lasers on Precision Manufacturing." Optics and Lasers in Engineering, 158, 107000.

4. Chen, L. and Zhang, Y. (2022). "Integration of Laser-Based Additive Manufacturing in Industry 4.0 Ecosystems." Additive Manufacturing, 49, 102486.

5. Brown, K. (2021). "Laser Technology in Aerospace Manufacturing: Challenges and Opportunities." Progress in Aerospace Sciences, 120, 100681.

6. Lee, S. et al. (2023). "Sustainability Aspects of Laser-Based Manufacturing Processes: A Systematic Review." Journal of Cleaner Production, 380, 134971.