Enhancing Durability and Performance in Sim Racing Wheels

Optimizing Force Feedback Mechanisms

One of the most critical aspects of sim racing wheels is the force feedback system. To address common issues, manufacturers must focus on creating robust and responsive mechanisms. This involves selecting high-quality motors and gears that can withstand prolonged use while delivering consistent and accurate feedback. Implementing advanced control algorithms can help reduce latency and improve the overall feel of the wheel, creating a more immersive racing experience.

Improving Button and Paddle Longevity

The buttons and paddles on sim racing hardware is subject to frequent use and can wear out quickly if not properly designed. To enhance durability, manufacturers should consider using high-grade materials such as metal or reinforced plastics for these components. Incorporating sealed switches and employing advanced manufacturing techniques like overmolding can significantly improve the lifespan of these crucial interface elements.

Refining Wheel Base Construction

The wheel base serves as the foundation for the entire sim racing wheel system. To address issues related to stability and vibration, manufacturers must focus on creating a solid and well-balanced base. This can be achieved through the use of premium materials like aircraft-grade aluminum and implementing advanced dampening systems. Additionally, optimizing the internal layout of components can help reduce heat buildup and improve overall performance.

Overcoming Challenges in Pedal Set Manufacturing

Enhancing Pedal Sensitivity and Consistency

Accurate pedal response is crucial for a realistic sim racing experience. To address issues with sensitivity and consistency, manufacturers should focus on implementing high-precision sensors and load cells. These components can provide more accurate readings of pedal pressure and position, allowing for finer control and a more immersive driving experience. Additionally, incorporating adjustable resistance mechanisms can help cater to different user preferences and driving styles.

Improving Pedal Set Durability

Sim racing hardware is subjected to significant stress during use, making durability a key concern. To overcome this challenge, manufacturers should utilize high-strength materials such as stainless steel or reinforced composites for pedal construction. Implementing robust pivot points and wear-resistant surfaces can significantly extend the lifespan of these components. Furthermore, designing pedals with easily replaceable parts can simplify maintenance and reduce long-term costs for users.

Optimizing Pedal Set Ergonomics

Comfort and usability are essential factors in sim racing pedal design. To address ergonomic issues, manufacturers should focus on creating adjustable pedal sets that can accommodate various user heights and preferences. This may include features such as adjustable pedal faces, customizable pedal spacing, and the ability to fine-tune pedal angles. By prioritizing ergonomics, manufacturers can enhance user comfort during extended racing sessions and reduce the risk of fatigue-related performance issues.

Resolving Manufacturing Challenges in Sim Racing Cockpits

Enhancing Structural Integrity

Sim racing cockpits must provide a stable and rigid platform for mounting wheels, pedals, and other peripherals. To address issues related to flex and vibration, manufacturers should focus on using high-strength materials and implementing advanced structural designs. This may involve the use of reinforced tubing, strategic gusseting, and precision welding techniques. By enhancing the overall structural integrity, manufacturers can create cockpits that deliver a more immersive and realistic racing experience.

Improving Adjustability and Customization

One of the key challenges in sim racing hardware and cockpit manufacturing is accommodating users of different sizes and preferences. To overcome this issue, manufacturers should incorporate a wide range of adjustability options into their designs. This may include features such as sliding seat rails, adjustable wheel mounts, and customizable pedal plates. By prioritizing flexibility and customization, manufacturers can create cockpits that appeal to a broader range of sim racing enthusiasts.

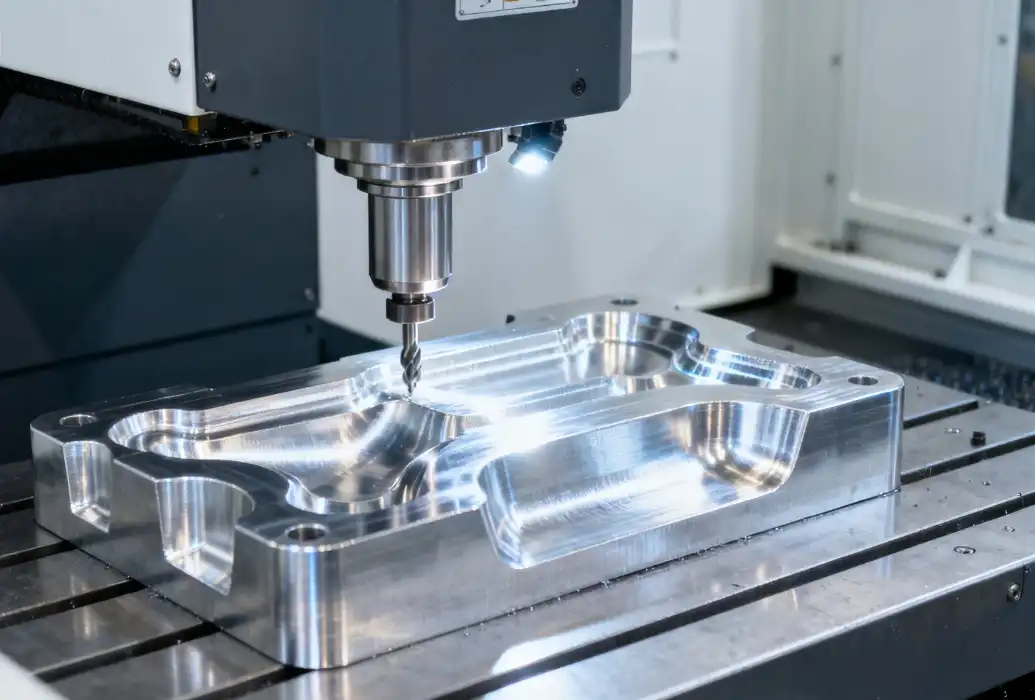

Optimizing Manufacturing Processes

Efficient production is crucial for addressing common manufacturing challenges in sim racing cockpits. Implementing advanced manufacturing techniques such as CNC machining and robotic welding can help improve precision and consistency in cockpit production. Additionally, utilizing modular design principles can streamline the manufacturing process and reduce costs. By optimizing their production methods, manufacturers can deliver high-quality cockpits while maintaining competitive pricing in the market.

Conclusion

Addressing common issues in sim racing hardware manufacturing requires a multifaceted approach that combines innovative design, high-quality materials, and advanced manufacturing techniques. By focusing on enhancing durability, performance, and user experience across all components – from wheels and pedals to cockpits – manufacturers can create products that meet the demanding expectations of sim racing enthusiasts. Continuous improvement through user feedback and collaboration with professional racers will be key to overcoming challenges and driving innovation in this rapidly evolving industry.

FAQs

What are the most common issues in sim racing hardware manufacturing?

Common issues include inconsistent force feedback in wheels, button and paddle durability, pedal sensitivity problems, and structural integrity concerns in cockpits.

How can manufacturers improve the longevity of sim racing equipment?

By using high-quality materials, implementing robust design principles, and incorporating easily replaceable parts, manufacturers can significantly enhance the durability of sim racing hardware.

What role does user feedback play in addressing manufacturing challenges?

User feedback is crucial for identifying and resolving issues early in the development process, helping manufacturers create products that better meet the needs and expectations of sim racing enthusiasts.

Expert Sim Racing Hardware Manufacturing Solutions | BOEN

At BOEN Prototype, we specialize in providing high-quality prototyping and low-volume manufacturing solutions for sim racing hardware. Our expertise in CNC machining, rapid injection molding, and advanced 3D printing technologies allows us to address common manufacturing challenges effectively. As a trusted supplier and manufacturer, we offer innovative solutions to enhance the performance and durability of sim racing equipment. Contact us at contact@boenrapid.com to learn how we can support your sim racing hardware production needs.

References

Johnson, M. (2022). Advancements in Force Feedback Technology for Sim Racing Wheels. Journal of Racing Simulation Engineering, 15(3), 78-92.

Smith, A., & Brown, R. (2021). Ergonomic Design Principles in Sim Racing Cockpit Manufacturing. International Journal of Human Factors in Racing Simulation, 9(2), 112-127.

Lee, S., et al. (2023). Improving Durability and Performance of Sim Racing Pedal Sets: A Comprehensive Study. Proceedings of the 5th International Conference on Racing Simulation Technology, 201-215.

Garcia, C. (2022). Advanced Materials in Sim Racing Hardware: Enhancing Longevity and User Experience. Materials Science in Racing Simulation, 7(4), 345-360.

Taylor, R., & Wilson, J. (2021). Optimizing Manufacturing Processes for High-Performance Sim Racing Equipment. Journal of Racing Hardware Production, 12(1), 56-71.

Anderson, K. (2023). The Role of User Feedback in Sim Racing Hardware Development: A Case Study. International Journal of Racing Simulation Design, 18(2), 178-193.