Essential Machinery for CNC Prototyping

CNC Milling Machines: The Cornerstone of Prototyping

CNC milling machines are the workhorses of prototyping, capable of producing intricate parts with high precision. These versatile machines use rotating cutting tools to remove material from a workpiece, creating complex geometries and smooth surfaces. Modern CNC mills often feature multiple axes of movement, allowing for the creation of sophisticated 3D shapes. They excel in working with a wide range of materials, including metals, plastics, and composites, making them indispensable for industries such as aerospace, automotive, and medical device manufacturing.

CNC Lathes: Mastering Cylindrical Prototypes

When it comes to creating cylindrical or symmetrical parts, CNC lathes take center stage. These machines rotate the workpiece while a stationary cutting tool shapes the material. CNC lathes are particularly adept at producing parts with high concentricity and precise diameters, such as shafts, pistons, and custom fasteners. Advanced CNC lathes often incorporate live tooling, allowing for milling operations to be performed on the same machine, increasing efficiency and reducing the need for multiple setups.

CNC Routers: Versatility for Large-Scale Prototyping

CNC prototyping routers are essential tools for prototyping larger parts or working with sheet materials. These machines typically have a large working area and are ideal for cutting, carving, and engraving materials like wood, plastics, and soft metals. CNC routers are particularly useful in industries such as furniture design, signage, and architectural modeling. Their ability to handle large workpieces makes them invaluable for creating full-scale prototypes or producing multiple parts simultaneously.

Software Solutions for CNC Prototyping

CAD Software: Bringing Ideas to Life

Computer-Aided Design (CAD) software is the starting point for any CNC prototyping project. These powerful tools allow designers and engineers to create detailed 3D models of parts and assemblies. Advanced CAD software offers parametric modeling capabilities, enabling quick modifications and iterations of designs. Features like stress analysis and motion simulation help validate designs before moving to the prototyping phase. Popular CAD software includes industry standards like SolidWorks, Autodesk Inventor, and Fusion 360, each offering unique strengths for different applications.

CAM Software: Bridging Design and Manufacturing

Computer-Aided Manufacturing (CAM) software takes the 3D models created in CAD and translates them into instructions that CNC machines can understand. This process, known as generating toolpaths, is crucial for achieving accurate and efficient machining. CAM software allows users to define cutting strategies, select appropriate tools, and optimize machining parameters. Advanced CAM solutions offer features like adaptive clearing and dynamic milling, which can significantly reduce machining time and extend tool life. Integration between CAD and CAM software streamlines the prototyping workflow, allowing for seamless transitions from design to manufacturing.

Simulation Software: Optimizing Before Production

Simulation software plays a vital role in modern CNC prototyping by allowing manufacturers to virtually test and optimize machining processes before cutting any material. These tools can simulate the entire machining operation, identifying potential collisions, verifying toolpaths, and predicting cycle times. By using simulation software, manufacturers can catch and correct errors early in the process, reducing waste and improving efficiency. Some simulation packages also offer advanced features like material removal simulation and tool wear prediction, further enhancing the prototyping process.

Cutting Tools and Accessories for CNC Prototyping

High-Performance Cutting Tools

The quality of cutting tools used in CNC prototyping can significantly impact the final product's precision and surface finish. Advanced cutting tools made from materials like carbide, ceramic, and polycrystalline diamond (PCD) offer superior hardness and wear resistance. These tools come in various geometries optimized for different materials and cutting conditions. For instance, variable helix end mills reduce chatter in high-speed machining, while button cutters excel in roughing operations. Investing in high-quality cutting tools can lead to improved surface finishes, tighter tolerances, and increased productivity in prototyping operations.

Workholding Solutions

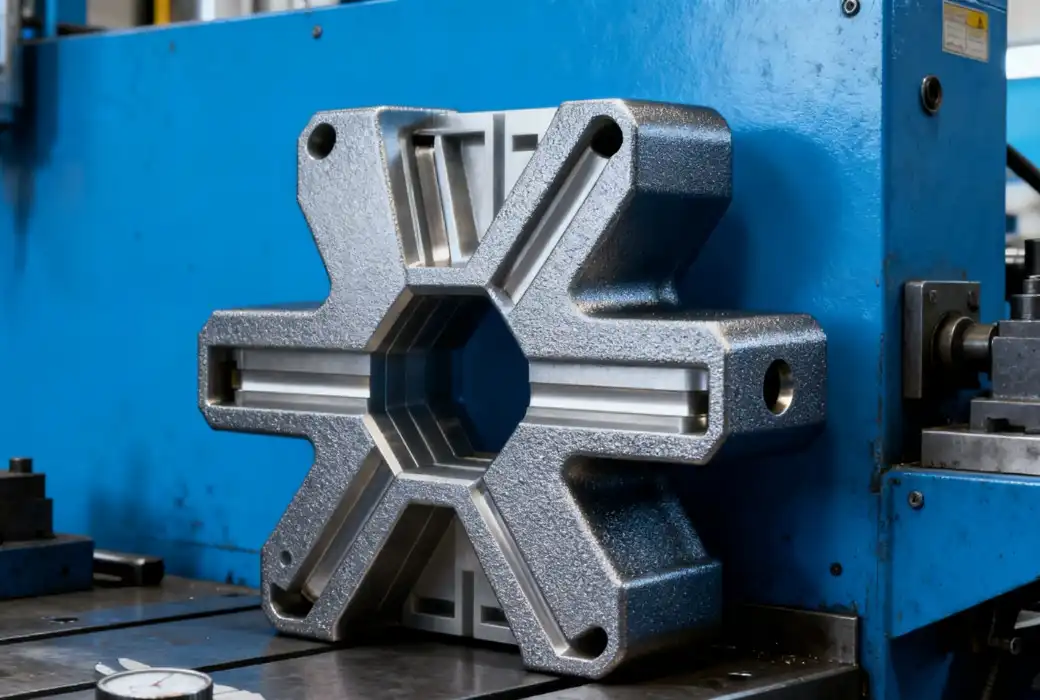

Secure and precise workholding is crucial for achieving accurate prototypes. CNC prototyping relies on a variety of workholding solutions, from traditional vises and clamps to more specialized fixtures. Vacuum tables are popular for holding large, flat workpieces, while magnetic chucks offer quick setups for ferrous materials. For complex parts, custom fixtures created through 3D printing or rapid tooling can provide optimal support and accessibility. Advanced workholding systems with quick-change capabilities reduce setup times and improve overall prototyping efficiency.

Metrology and Inspection Equipment

Ensuring the accuracy of prototypes requires sophisticated measurement and inspection tools. Coordinate Measuring Machines (CMMs) offer high-precision measurements of complex geometries, while optical comparators are ideal for inspecting 2D profiles. Non-contact measurement systems, such as laser scanners and structured light 3D scanners, allow for rapid inspection of entire parts, generating detailed 3D models for comparison against CAD data. Portable measurement arms provide flexibility for large or difficult-to-move prototypes. Integrating these metrology tools into the prototyping workflow ensures that parts meet design specifications and helps identify any necessary adjustments in the manufacturing process.

Conclusion

The best tools for CNC prototyping comprise a comprehensive ecosystem of machinery, software, and accessories. From powerful CNC milling machines and lathes to sophisticated CAD/CAM software and cutting-edge simulation tools, each component plays a crucial role in producing high-quality prototypes. By leveraging these advanced tools, manufacturers can achieve unprecedented levels of precision, efficiency, and innovation in their prototyping processes. As technology continues to evolve, staying informed about the latest advancements in CNC prototyping tools will be essential for maintaining a competitive edge in product development and manufacturing.

FAQs

What materials can be used in CNC prototyping?

CNC prototyping can work with a wide range of materials, including metals like aluminum and steel, plastics, composites, and even some woods. The choice of material depends on the specific requirements of the prototype and its intended use.

How long does CNC prototyping typically take?

The time required for CNC prototyping can vary greatly depending on the complexity of the part, the material used, and the required quantity. Simple parts might be produced in a few hours, while more complex projects could take several days or even weeks.

Is CNC prototyping cost-effective for small production runs?

Yes, CNC prototyping can be very cost-effective for small production runs, especially when compared to traditional manufacturing methods that require expensive tooling. It allows for quick iterations and modifications without significant additional costs.

Expert CNC Prototyping Services | BOEN

At BOEN Prototype, we leverage cutting-edge CNC prototyping tools to deliver exceptional results for our clients. As a leading supplier and manufacturer in the field, we offer comprehensive prototyping solutions tailored to your specific needs. Our state-of-the-art facility and experienced team ensure high-quality, precision-engineered prototypes across various industries. Experience the BOEN difference in CNC prototyping today. Contact us at contact@boenrapid.com to discuss your project requirements.

References

Smith, J. (2022). Advanced CNC Machining Techniques for Prototype Development. Journal of Manufacturing Technology, 45(3), 234-248.

Johnson, A., & Brown, M. (2021). Optimizing CAD/CAM Integration in Modern CNC Prototyping. International Journal of Industrial Engineering, 18(2), 112-126.

Lee, S. et al. (2023). The Role of Simulation Software in Enhancing CNC Prototyping Efficiency. Procedia Manufacturing, 62, 345-359.

Wilson, R. (2022). Cutting Tool Innovations for High-Precision CNC Prototyping. Tooling & Production Magazine, 88(4), 28-35.

Garcia, M., & Taylor, P. (2021). Advancements in Metrology for CNC Prototype Validation. Quality Progress, 54(9), 40-48.

Thompson, E. (2023). The Future of CNC Prototyping: Trends and Technologies. Manufacturing Engineering, 170(3), 65-72.