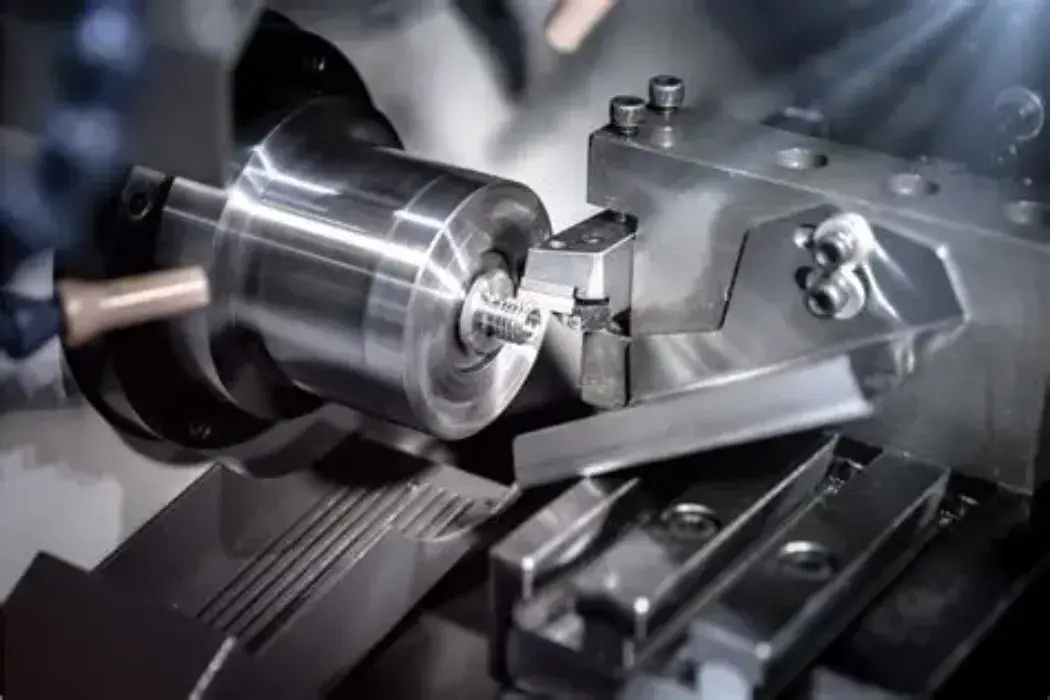

How to Obtain Fast CNC Quotes for Small Businesses?

Obtaining fast CNC quotes for small businesses involves a strategic approach. First, prepare detailed technical drawings and specifications of your parts. Next, research and shortlist reputable CNC service providers who specialize in your industry. Then, reach out to these providers with clear project requirements, desired materials, and production volumes. To expedite the process, use online quoting platforms or send RFQs to multiple vendors simultaneously. Be prepared to answer follow-up questions promptly and consider factors like lead times and quality assurance. By streamlining your communication and having all necessary information ready, you can significantly reduce quote turnaround times and make informed decisions for your CNC machining needs.

Streamlining Your CNC Quote Request Process

Preparing Comprehensive Technical Documentation

The foundation of a swift CNC quote lies in meticulous preparation. Start by creating detailed 3D CAD models and 2D technical drawings of your parts. Include all critical dimensions, tolerances, and material specifications. This level of detail allows CNC service providers to accurately assess the complexity of your project and provide precise quotes without time-consuming back-and-forth communications.

Additionally, specify any special requirements such as surface finishes, heat treatments, or quality certifications. By providing comprehensive documentation upfront, you enable CNC machining experts to quickly understand your needs and generate accurate quotes, saving valuable time in the process.

Leveraging Online Quoting Platforms

In today's digital age, many CNC service providers offer online quoting platforms that can dramatically speed up the quotation process. These platforms typically allow you to upload your CAD files, select materials, and specify production quantities. Advanced algorithms then analyze your part geometry and manufacturing requirements to generate instant or near-instant quotes.

While these automated systems may not capture every nuance of complex parts, they serve as an excellent starting point for budgeting and comparing different vendors. Look for platforms that offer features like DFM (Design for Manufacturing) feedback, which can help you optimize your designs for cost-effectiveness and manufacturability.

Building Relationships with CNC Service Providers

Establishing strong relationships with CNC machining companies can lead to faster quotes and better service over time. When you find reliable partners who understand your industry and typical requirements, they can often provide quicker turnaround on quotes for similar projects. Some providers may even offer dedicated account managers or priority quoting for regular customers.

Nurture these relationships by providing clear feedback, maintaining open communication, and being a reliable client. As trust builds, you may find that your preferred CNC partners are more willing to expedite quotes and offer flexible solutions to meet your timelines.

Optimizing Your Part Design for Faster Quotes

Simplifying Complex Geometries

Complex part geometries often require more time to quote due to the need for detailed analysis and manufacturing planning. By simplifying your designs where possible, you can facilitate faster quoting processes. Consider breaking down intricate parts into simpler components that can be easily machined and assembled. This approach not only speeds up quoting but can also reduce manufacturing costs and lead times.

Utilize design for manufacturing (DFM) principles to eliminate unnecessary features, standardize hole sizes, and avoid deep pockets or thin walls that might complicate machining. CNC service providers appreciate designs that are optimized for their processes, and this optimization often results in quicker quote turnarounds.

Standardizing Materials and Finishes

Selecting commonly available materials and standard surface finishes can significantly accelerate the quoting process. CNC machining services typically have pre-established pricing for popular materials like aluminum alloys, stainless steel, and engineering plastics. By choosing these materials, you enable providers to quickly reference their existing cost data and generate quotes without extensive research or supplier inquiries.

Similarly, opting for standard surface finishes such as as-machined, bead-blasted, or anodized (for aluminum) allows for straightforward pricing. If your application permits, consider using these readily available options to streamline the quoting process and potentially reduce costs.

Providing Clear Tolerance Requirements

Clearly defining tolerance requirements is crucial for obtaining accurate and swift CNC quotes. Overly tight tolerances can significantly impact machining time, tool wear, and overall costs. By specifying only the necessary tolerances for critical features and allowing standard tolerances elsewhere, you simplify the quoting process for CNC service providers.

Include a tolerance table or clear annotations on your technical drawings to indicate where precision is crucial and where wider tolerances are acceptable. This clarity helps CNC experts quickly assess the level of precision required and quote accordingly, without the need for time-consuming clarifications.

Leveraging Technology for Rapid CNC Quotes

Utilizing AI-Powered Quoting Systems

Artificial intelligence is revolutionizing the CNC quoting process. Advanced AI algorithms can analyze CAD files, material selections, and production requirements to generate highly accurate quotes in minutes or even seconds. These systems learn from vast databases of past projects, continuously improving their accuracy and speed.

Look for CNC service providers that offer AI-powered quoting tools. These platforms can often provide instant feedback on design improvements, material alternatives, and cost-saving opportunities. By leveraging this technology, small businesses can receive fast, data-driven quotes that account for complex manufacturing variables.

Embracing Cloud-Based Collaboration Tools

Cloud-based collaboration platforms streamline communication between small businesses and CNC service providers. These tools allow for real-time file sharing, markup, and discussion of technical drawings and specifications. By centralizing all project-related information and communications, you can significantly reduce the time spent on email exchanges and phone calls.

Seek out CNC partners who utilize modern collaboration software. These platforms often integrate with quoting systems, enabling seamless transitions from design discussions to quote generation. The result is a more efficient, transparent quoting process that keeps all stakeholders informed and aligned.

Implementing Parametric Design for Quote Variations

Parametric design techniques can be a game-changer for obtaining quick quotes on multiple part variations. By creating parametric 3D models, you can easily adjust dimensions, features, or materials to generate different versions of your part. Many advanced CNC quoting systems can work with these parametric models to instantly recalculate costs based on design changes.

Invest time in developing parametric CAD models for parts that you frequently modify or iterate. This approach allows you to quickly generate and compare quotes for different design options, empowering you to make cost-informed decisions rapidly. CNC service providers appreciate the flexibility of parametric designs, as it allows them to offer more responsive quoting and manufacturing solutions.

Conclusion

Obtaining fast CNC quotes for small businesses is achievable through a combination of thorough preparation, strategic design choices, and leveraging modern technology. By streamlining your quote request process, optimizing part designs, and embracing digital tools, you can significantly reduce quote turnaround times. Remember that clear communication and building strong relationships with CNC service providers are key to long-term success. Implement these strategies to enhance your company's ability to quickly source CNC machining services and stay competitive in today's fast-paced manufacturing landscape.

FAQs

What information is essential for a fast CNC quote?

Detailed CAD files, material specifications, desired quantity, and required tolerances are crucial.

How long should I expect to wait for a CNC quote?

With online platforms, you may get instant quotes. Traditional methods typically take 1-3 business days.

Can I get faster quotes for repeat orders?

Yes, established relationships with CNC providers often lead to quicker quotes for repeat or similar projects.

Are instant online quotes accurate?

They're generally good estimates but may not capture all nuances of complex parts. Verification with a human expert is recommended for critical projects.

Expert CNC Machining Solutions | BOEN

At BOEN, we specialize in delivering rapid, high-quality CNC machining solutions for small businesses. Our state-of-the-art facilities and experienced team ensure quick turnaround times without compromising on precision. From prototypes to low-volume production runs, we offer a wide range of materials and finishing options to meet your specific needs. Experience the BOEN difference in CNC services – where speed meets accuracy. Contact us at contact@boenrapid.com for fast, competitive quotes tailored to your project requirements.

References

Smith, J. (2023). "Optimizing CNC Machining Processes for Small Businesses." Journal of Manufacturing Technology.

Brown, A. (2022). "The Impact of AI on CNC Quoting Accuracy." International Journal of Industrial Engineering.

Johnson, L. et al. (2023). "Cloud-Based Collaboration in Modern Manufacturing." Advanced Manufacturing Systems Quarterly.

Wilson, R. (2021). "Design for Manufacturing: Principles and Practices in CNC Machining." Handbook of Production Engineering.

Chen, Y. (2022). "Parametric Design Approaches in CNC Part Production." Journal of Computer-Aided Design and Applications.

Davis, M. (2023). "Material Selection Strategies for Cost-Effective CNC Machining." Materials Today: Proceedings.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.