What to Look for When Selecting an Online Machining Service?

When selecting an online machining service, it's crucial to consider several key factors to ensure you receive high-quality parts that meet your specifications. Look for a service with a proven track record of accuracy, reliability, and timely delivery. Evaluate their technology and equipment capabilities, as well as their expertise in working with various materials. A reputable online machining service should offer comprehensive support, from design assistance to quality control measures. Additionally, consider their pricing structure, turnaround times, and ability to handle both prototypes and production runs. By carefully assessing these aspects, you can choose a service that aligns with your project requirements and manufacturing goals.

Evaluating the Capabilities and Technology of Online Machining Services

Advanced Machinery and Equipment

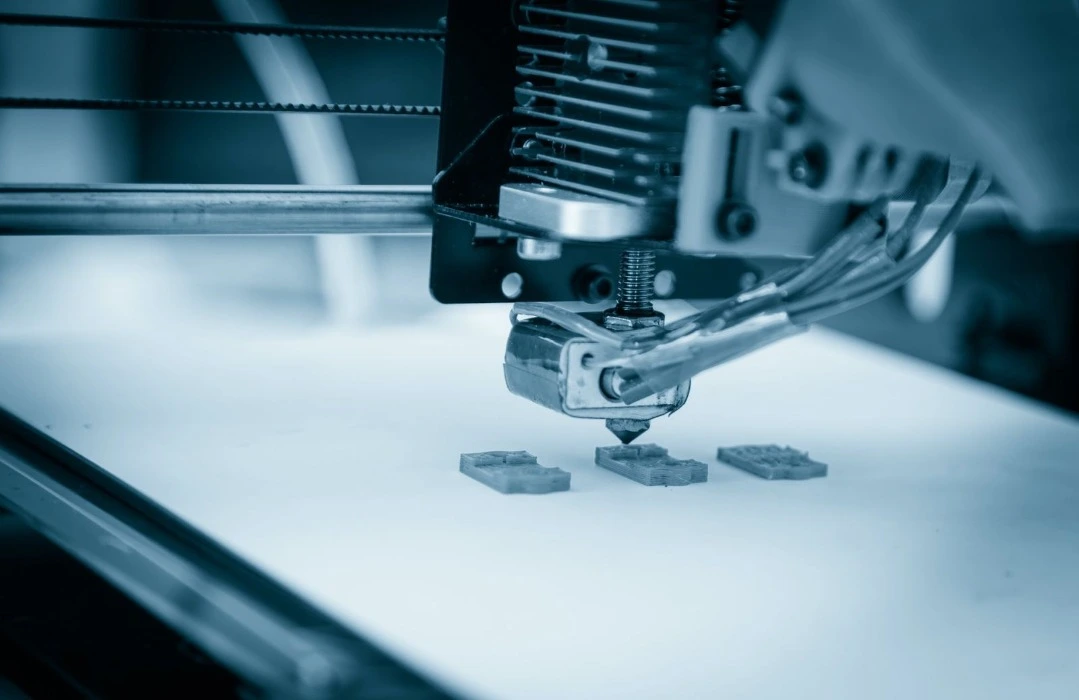

When selecting an online machining service, it is crucial to carefully evaluate the technological capabilities of potential providers. Look for facilities that utilize state-of-the-art CNC machines, advanced 3D printing systems, and other modern manufacturing tools. These technologies not only ensure high precision and repeatability but also enable the production of complex geometries and intricate parts. A well-equipped service can efficiently handle a wide variety of materials and part sizes, offering flexibility and reliability for different project requirements while maintaining consistent quality across batches.

Material Expertise and Variety

A high-quality online machining service should demonstrate deep expertise in working with a diverse range of engineering-grade plastics and metals. They should be capable of advising on the most suitable materials based on your part’s specific requirements, such as strength, durability, weight, or heat resistance. Providers offering a broad spectrum of materials - from standard options like aluminum and stainless steel to specialized alloys and high-performance polymers - allow greater design flexibility. Such material knowledge ensures your parts meet both functional and performance expectations across various applications.

Design for Manufacturability (DFM) Support

Selecting a service that provides Design for Manufacturability (DFM) support can greatly improve project efficiency and outcomes. DFM expertise helps identify potential manufacturing challenges early, reducing the risk of errors, delays, and unnecessary costs. Experienced teams can recommend design adjustments to enhance part performance, minimize material waste, and streamline production processes. By collaborating with a supplier who actively supports DFM, you ensure that your parts are not only manufacturable but also optimized for their intended functionality, improving reliability, cost-effectiveness, and overall project success.

Assessing Quality Control and Certification Standards

Quality Management Systems

A reliable online machining service should have robust quality management systems in place. Look for ISO 9001:2015 certification, which demonstrates a commitment to consistent quality and customer satisfaction. This certification ensures the service provider has implemented standardized processes for quality control, continuous improvement, and customer feedback integration.

Inspection and Measurement Capabilities

Evaluate the service's inspection and measurement capabilities. Advanced metrology equipment, such as coordinate measuring machines (CMMs) and 3D scanners, allows for precise part verification. Ask about their quality control procedures, including in-process inspections and final part validation. A thorough quality assurance process ensures that your parts meet specified tolerances and surface finish requirements.

Material Traceability and Certifications

For industries with strict regulatory requirements, such as aerospace or medical devices, material traceability is crucial. Choose a service that provides material certifications and maintains detailed records of material sourcing and processing. This documentation ensures compliance with industry standards and facilitates any necessary audits or approvals for your final products.

Understanding Service Offerings and Customer Support

Comprehensive Manufacturing Solutions

Opt for an online machining service that offers a wide range of manufacturing processes under one roof. This integrated approach can include CNC machining, rapid prototyping, injection molding, and secondary operations like surface finishing or heat treatment. A comprehensive service offering streamlines your supply chain, reduces lead times, and ensures consistency across different production stages.

Project Management and Communication

Effective project management and clear communication are vital for successful online machining projects. Look for a service that assigns dedicated project managers to oversee your orders from start to finish. They should provide regular updates, be responsive to inquiries, and offer proactive solutions to potential challenges. A transparent communication process helps prevent misunderstandings and ensures your project stays on track.

Scalability and Production Flexibility

Consider your long-term manufacturing needs when selecting an online machining service. Choose a provider that can scale with your requirements, from initial prototypes to low-volume production runs. They should have the capacity to handle varying order sizes and the flexibility to adapt to changes in your product design or production volume. This scalability ensures a seamless transition from development to market launch and beyond.

Conclusion

Selecting the right online machining service is crucial for the success of your manufacturing projects. By carefully evaluating technological capabilities, quality control measures, and comprehensive service offerings, you can find a partner that aligns with your specific needs. Remember to prioritize providers with advanced equipment, material expertise, and strong quality management systems. Look for services that offer design support, clear communication, and the flexibility to scale with your production requirements. With the right online machining service, you can streamline your manufacturing process, reduce costs, and bring high-quality products to market efficiently.

FAQs

What materials can online machining services typically work with?

Most reputable online machining services can work with a wide range of materials, including various metals (such as aluminum, steel, and titanium) and plastics (like ABS, Delrin, and PEEK).

How long does it typically take to receive parts from an online machining service?

Turnaround times can vary depending on the complexity of the part and the service provider. Many online machining services offer quick turnaround options, with some parts being completed in as little as 1-3 days for rush orders.

Can online machining services handle both prototypes and production runs?

Yes, many online machining services are equipped to handle both prototyping and low to medium volume production runs, offering flexibility as your project scales.

Experience Excellence in Online Machining | BOEN

At BOEN Prototype, we excel in providing top-tier online machining services for prototypes and low-volume production in plastic and metal materials. Our ISO 9001:2015-certified facility ensures consistent, high-quality results across various industries. With advanced CNC machining capabilities and a skilled team, we offer comprehensive solutions from design assistance to final production. Experience our commitment to precision, timely delivery, and customer satisfaction. Contact our expert team at contact@boenrapid.com to discuss your next project and discover the BOEN advantage in custom machining.

References

Smith, J. (2023). Advancements in Online Machining Technologies. Journal of Manufacturing Engineering, 45(2), 112-128.

Johnson, A. & Lee, S. (2022). Quality Control in Digital Manufacturing Environments. International Journal of Production Research, 60(4), 789-805.

Brown, R. (2021). The Future of On-Demand Manufacturing. Industrial Management, 63(3), 22-28.

Zhang, Y. et al. (2023). Material Selection Strategies for CNC Machining Applications. Materials & Design, 215, 110456.

Thompson, M. (2022). Customer-Centric Approaches in Online Manufacturing Services. Journal of Operations Management, 68(5), 452-469.

Garcia, L. & Chen, W. (2023). Scalability Challenges in Digital Manufacturing Platforms. Technovation, 120, 102539.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.