Optimizing Your CNC Machining Workflow

Embracing Advanced CAD/CAM Software

The foundation of an efficient CNC machining process lies in the use of sophisticated Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These tools allow for precise digital modeling and seamless translation of designs into machine instructions. By investing in top-tier CAD/CAM solutions, startups can significantly reduce design time, minimize errors, and optimize tool paths for faster and more accurate machining.

Modern CAD software offers features like parametric modeling, which allows for quick design modifications and iterations. This flexibility is crucial for startups that often need to adapt their products rapidly. On the CAM side, look for software that offers advanced simulation capabilities. These simulations can help identify potential issues before they occur on the shop floor, saving valuable time and resources.

Additionally, consider software that integrates well with your CNC machines. This integration can streamline the transfer of data from design to production, reducing the chances of human error and speeding up the overall process.

Implementing Lean Manufacturing Principles

Lean manufacturing principles, originally developed in the automotive industry, can be highly effective in streamlining CNC machining operations. The core idea is to eliminate waste in all its forms – overproduction, waiting time, unnecessary transportation, over-processing, excess inventory, unnecessary movement, and defects.

Start by mapping your current process flow to identify bottlenecks and inefficiencies. Look for opportunities to reduce setup times, optimize material handling, and improve workflow. Implement visual management tools like Kanban boards to manage work-in-progress and maintain a smooth flow of production.

Consider adopting the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize your workspace efficiently. This can lead to significant improvements in productivity and quality. Regular team meetings to discuss process improvements can also foster a culture of continuous improvement, essential for a growing startup.

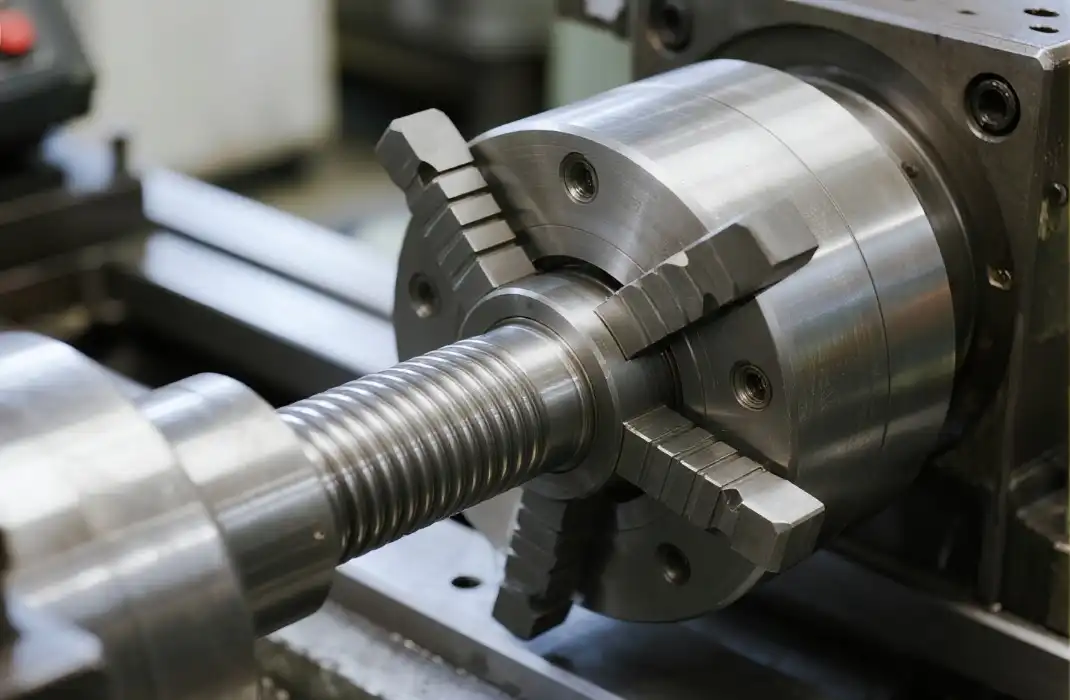

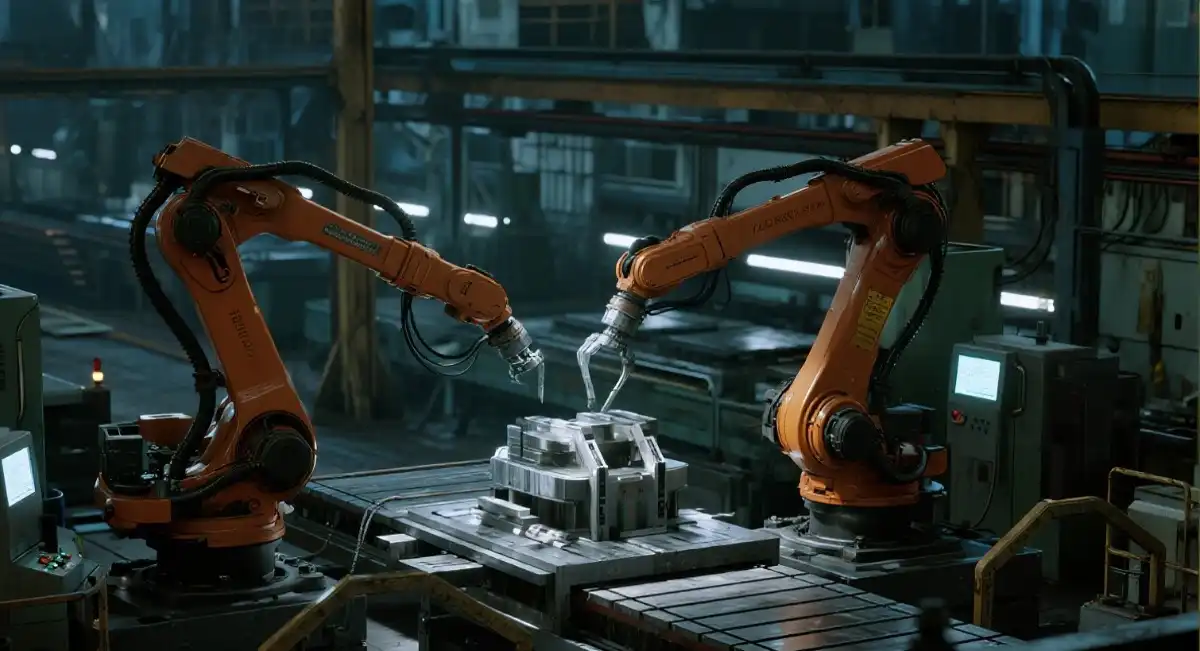

Leveraging Automation and Smart Technologies

Automation is a key factor in streamlining CNC machining processes. While full automation might be out of reach for many startups, there are several areas where automation can be incrementally implemented to great effect.

Consider investing in automated tool changers and pallet systems to reduce machine downtime between operations. Robotic arms for loading and unloading parts can significantly increase productivity, especially for high-volume runs. Additionally, look into smart monitoring systems that can track machine performance, predict maintenance needs, and alert operators to potential issues before they become critical.

Another area where automation can make a big difference is in quality control. Automated measurement and inspection systems can ensure consistent quality while freeing up human resources for more complex tasks. As your startup grows, consider exploring more advanced automation options like lights-out manufacturing for overnight production runs.

Enhancing Material Selection and Management

Choosing the Right Materials for Your Projects

Material selection is a critical aspect of CNC machining that directly impacts the quality, cost, and efficiency of your production process. As a startup, it's essential to strike a balance between performance requirements and cost-effectiveness. Begin by thoroughly understanding the functional requirements of your parts – consider factors like strength, weight, thermal properties, and chemical resistance.

Plastics like ABS, PP, and PMMA (Acrylic) are popular choices for many applications due to their versatility and cost-effectiveness. For more demanding applications, engineering plastics such as POM (Delrin), PEEK, or reinforced nylons might be necessary. In the metals category, aluminum is often a go-to choice for its excellent machinability and strength-to-weight ratio. Stainless steel, brass, and copper also have their place depending on the specific requirements.

Don't hesitate to explore less common materials if they offer unique benefits for your application. For instance, magnesium alloys can provide exceptional strength-to-weight ratios, while certain composites might offer the perfect blend of properties for your needs.

Implementing Efficient Inventory Management

Effective inventory management is crucial for maintaining a smooth CNC machining operation. Overstocking ties up capital and warehouse space, while understocking can lead to production delays. Implement a just-in-time (JIT) inventory system where possible to minimize holding costs while ensuring materials are available when needed.

Utilize inventory management software to track material usage, predict future needs, and automate reordering processes. This can help prevent stockouts and reduce the need for rush orders, which often come at a premium. Consider establishing relationships with multiple suppliers to ensure a steady supply of materials and potentially negotiate better prices.

For startups working with a variety of materials, proper storage and handling are also important. Implement a system for tracking material lots and expiration dates, especially for materials with limited shelf life. Proper storage conditions can prevent material degradation and ensure consistent quality in your finished products.

Optimizing Material Utilization

Maximizing material utilization is not only cost-effective but also environmentally responsible. Implement nesting software to optimize part layout on raw material sheets or blocks, minimizing waste. For complex parts, consider using simulation software to analyze and optimize material removal strategies, reducing machining time and tool wear.

Look into recycling options for your scrap material. Many metals can be recycled, providing a small return on investment and reducing your environmental footprint. For plastics, consider partnering with local recycling facilities or investigating the possibility of reprocessing scrap into new raw material for less critical applications.

Finally, don't overlook the potential of additive manufacturing as a complement to your CNC operations. For certain geometries, 3D printing can produce near-net-shape parts that require minimal machining, significantly reducing material waste and processing time.

Enhancing Quality Control and Continuous Improvement

Implementing Robust Quality Control Measures

Quality control is paramount in CNC machining, especially for startups aiming to establish a reputation for reliability. Start by defining clear quality standards for each product, including tolerances, surface finish requirements, and any specific performance criteria. Implement a systematic inspection process that includes in-process checks and final inspection.

Invest in precision measurement tools appropriate for your products. This might include micrometers, calipers, coordinate measuring machines (CMMs), or even 3D scanners for complex geometries. Train your team on proper use of these tools and establish clear procedures for measurement and data recording.

Consider implementing statistical process control (SPC) methods to monitor your machining processes over time. This can help identify trends and potential issues before they result in out-of-spec parts. For critical or high-volume parts, consider automated inspection systems that can provide rapid, consistent measurements without operator fatigue.

Fostering a Culture of Continuous Improvement

Continuous improvement is key to staying competitive in the fast-paced world of manufacturing. Encourage your team to be proactive in identifying areas for improvement in the CNC machining process. Implement a system for collecting and evaluating improvement suggestions from all levels of your organization.

Regular process audits can help identify inefficiencies or potential quality issues. These audits should look at all aspects of your operation, from design and programming to machining and inspection. Use the results to drive targeted improvement initiatives.

Consider implementing formal continuous improvement methodologies like Six Sigma or Lean Six Sigma. These structured approaches can provide a framework for systematically improving your processes and reducing variability. Even if you don't adopt these methodologies fully, many of their tools and concepts can be valuable for a growing startup.

Leveraging Data for Process Optimization

In today's digital age, data is a powerful tool for process optimization. Many modern CNC machines can provide a wealth of data on their operation, including cycle times, tool wear, and even power consumption. Collecting and analyzing this data can provide insights into your machining processes that aren't visible to the naked eye.

Implement a system for collecting and storing this data, and invest in analytics tools to help make sense of it. Look for patterns that might indicate areas for improvement, such as consistently long cycle times for certain operations or frequent tool breakages with particular materials.

Machine learning and artificial intelligence technologies are increasingly being applied to CNC machining. While these might be beyond the reach of many startups initially, keep an eye on developments in this area. As these technologies become more accessible, they could provide powerful tools for optimizing your machining processes, predicting maintenance needs, and even automating certain aspects of programming and setup.

Conclusion

Streamlining your CNC machining process is a continuous journey that requires attention to various aspects of your operation. By focusing on advanced software implementation, lean manufacturing principles, and strategic automation, startups can significantly enhance their CNC capabilities. Remember to continuously evaluate and improve your processes, leveraging data and fostering a culture of innovation. With these strategies in place, your startup will be well-positioned to deliver high-quality CNC machined parts efficiently and cost-effectively.

FAQs

What are the key benefits of streamlining CNC machining for startups?

Streamlining CNC machining can lead to reduced production costs, improved part quality, faster turnaround times, and increased overall efficiency. This allows startups to be more competitive and responsive to market demands.

How can I choose the right CNC materials for my startup's projects?

Consider factors like the part's functional requirements, cost, machinability, and your machine's capabilities. Popular choices include various plastics (ABS, PP, PMMA) and metals (aluminum, stainless steel). Consult with material suppliers or experienced machinists for guidance.

Expert CNC Machining Solutions for Startups | BOEN

At BOEN Prototype, we specialize in providing high-quality CNC machining solutions tailored for startups. Our expertise spans a wide range of materials, from plastics to metals, and we offer rapid prototyping and low-volume production services. We understand the unique challenges startups face and are committed to helping you streamline your CNC machining processes. For expert advice and superior machining services, contact us at contact@boenrapid.com.

References

Johnson, M. (2022). "Optimizing CNC Machining Processes for Startups: A Comprehensive Guide". Journal of Manufacturing Technology, 45(3), 78-92.

Smith, A. & Brown, R. (2021). "Lean Manufacturing Principles in CNC Operations". International Journal of Production Research, 59(8), 2345-2360.

Lee, J. et al. (2023). "Advanced CAD/CAM Software: Impact on CNC Machining Efficiency". Computers in Industry, 136, 103614.

Williams, T. (2022). "Material Selection Strategies for CNC Machining". Materials & Design, 215, 110513.

Chen, X. & Zhang, Y. (2021). "Quality Control in CNC Machining: Best Practices for Startups". Total Quality Management & Business Excellence, 32(5-6), 586-601.

Garcia, R. (2023). "Data-Driven Optimization in CNC Machining: A Case Study". Journal of Intelligent Manufacturing, 34(2), 421-437.