How to Compare CNC Suppliers: A Comprehensive Checklist?

Choosing the right CNC supplier is crucial for successful manufacturing projects. To help you make an informed decision, we've created a comprehensive checklist for comparing CNC suppliers. This guide covers key factors such as technical capabilities, quality control measures, pricing, and customer service. By thoroughly evaluating potential suppliers using these criteria, you can ensure you select a partner that meets your specific needs and delivers high-quality CNC machined parts consistently. Let's dive into the essential aspects to consider when comparing CNC suppliers.

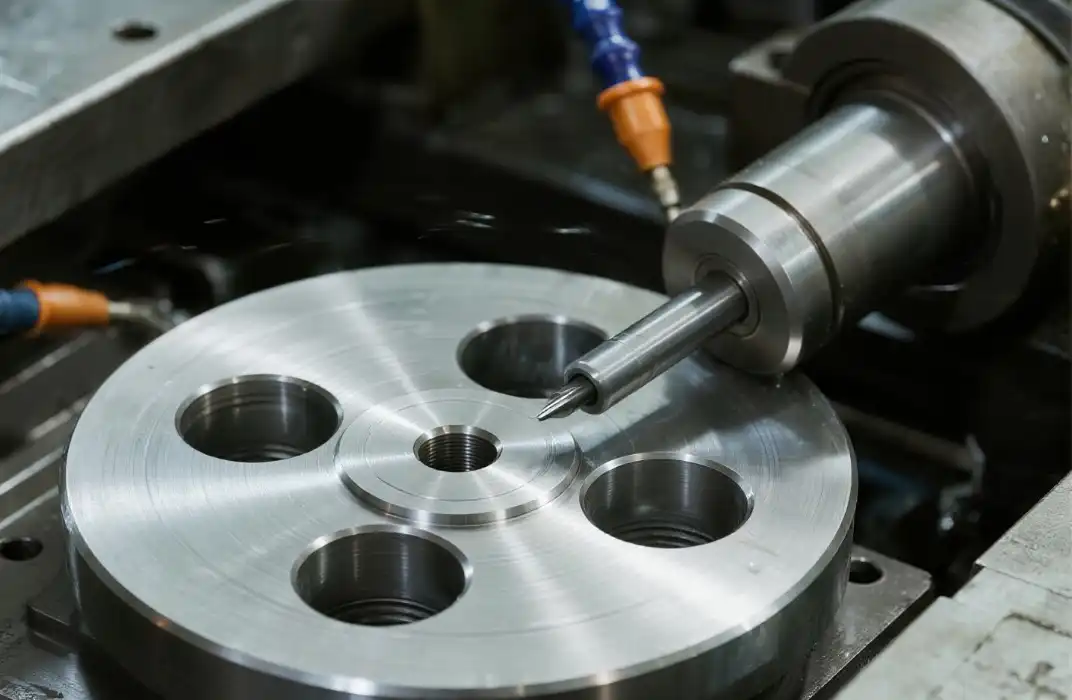

Evaluating Technical Capabilities and Equipment

Machinery and Technology

When evaluating CNC suppliers, it is essential to closely review their available machinery and technological capabilities. A supplier equipped with advanced multi-axis machining centers, precision turning equipment, and automated inspection tools is more likely to deliver complex geometries with high accuracy. The integration of modern CAD/CAM software is equally important, as it determines how effectively designs are translated into finished parts. Suppliers that invest in the latest technology can achieve shorter cycle times, tighter tolerances, and greater overall efficiency in production.

Material Expertise

Material expertise plays a critical role in choosing reliable CNC suppliers. The ability to work with a wide variety of materials—ranging from metals like stainless steel, aluminum, and titanium to engineering plastics such as ABS, POM, and PEEK—ensures versatility across different applications. Suppliers experienced with specialized materials for industries like aerospace, medical devices, or automotive can better support project-specific needs. A broad material portfolio not only enhances flexibility but also demonstrates a supplier’s technical competence in delivering durable and high-quality components.

Production Capacity

Assessing production capacity is fundamental to ensuring your CNC supplier can handle both current and future requirements. Consider the number of machines in operation, their level of automation, and how production shifts are scheduled to meet demand. A supplier with scalable capacity is better positioned to manage urgent requests, prototype development, and full-scale production without delays. Strong production capacity also reduces the risk of bottlenecks, enabling suppliers to maintain consistent quality standards and on-time delivery even when handling large or complex projects.

Assessing Quality Control and Certifications

Quality Management Systems

When selecting CNC suppliers, it is essential to evaluate the robustness of their quality management systems. Suppliers holding ISO 9001:2015 certification demonstrate adherence to global standards for quality consistency and continuous improvement. Beyond certification, investigate how they implement in-process inspections, traceability protocols, and final quality checks. A well-structured system minimizes the risk of defects and ensures each part conforms to required specifications. This not only supports product reliability but also builds long-term confidence in the supplier’s manufacturing capabilities.

Metrology and Inspection Equipment

Accurate metrology and inspection tools are central to maintaining precision in CNC machining. Suppliers should be equipped with advanced technologies such as coordinate measuring machines (CMMs), optical comparators, surface roughness testers, and digital microscopes. These instruments enable verification of critical dimensions and tolerances at every stage of production. A strong inspection capability ensures early detection of deviations, reduces rework, and guarantees parts meet engineering requirements. Partnering with a supplier that invests in advanced metrology helps safeguard both quality and efficiency in production.

Industry-Specific Certifications

Industry-specific certifications provide additional assurance that a CNC supplier can meet specialized requirements. For aerospace manufacturers, AS9100 certification validates compliance with strict aviation standards. Medical device projects require suppliers certified under ISO 13485 to ensure alignment with regulatory and safety guidelines. Automotive, energy, and defense sectors may also demand specific credentials. Choosing a supplier with the right certifications confirms their expertise, strengthens supply chain credibility, and reduces the risk of compliance issues. Such credentials highlight the supplier’s readiness to serve demanding global industries.

Comparing Pricing, Lead Times, and Customer Service

Transparent Pricing Structure

When comparing CNC suppliers, carefully analyze their pricing structure to ensure it is both clear and reliable. A transparent quotation should break down material costs, machining time, labor, and any value-added services such as finishing or assembly. Hidden costs or overly low prices can signal potential issues, including substandard materials or shortcuts in production. Instead of choosing solely based on the lowest bid, evaluate the overall value offered, balancing affordability with consistent quality, delivery reliability, and post-production support.

Lead Time Performance

Lead times are a critical factor in determining the reliability of a CNC supplier. A dependable partner should provide realistic project timelines and demonstrate a proven record of meeting deadlines across varying production volumes. Request data on their average turnaround times, flexibility in handling urgent orders, and contingency planning for unexpected disruptions. Consistent lead time performance ensures smooth product development cycles, minimizes costly delays, and supports agile market entry strategies—especially important for startups or businesses scaling production rapidly.

Customer Support and Communication

Strong customer support and effective communication are vital for managing CNC machining projects efficiently. Evaluate how quickly and professionally the supplier responds to inquiries, as well as the technical expertise of their support staff. Suppliers offering dedicated project managers or engineers provide better guidance throughout design and production. Clear communication channels help resolve issues quickly, prevent misunderstandings, and ensure alignment with your requirements. High-quality customer service not only simplifies collaboration but also builds long-term partnerships based on trust and reliability.

Conclusion

Selecting the right CNC suppliers are critical decision that can significantly impact your manufacturing projects. By thoroughly evaluating technical capabilities, quality control measures, pricing structures, and customer service, you can make an informed choice. Remember to consider factors such as material expertise, production capacity, and industry-specific certifications. A comprehensive comparison using this checklist will help you find a CNC supplier that not only meets your immediate needs but can also support your long-term manufacturing goals.

FAQs

What should I look for in a CNC supplier's equipment?

Look for modern CNC machines, multi-axis capabilities, and advanced CAD/CAM software.

How important are quality certifications?

Very important. ISO 9001:2015 is a must, and industry-specific certifications like AS9100 for aerospace are crucial.

What's the best way to assess a supplier's lead times?

Ask for average lead times on different project types and check their on-time delivery track record.

Why Choose BOEN for Your CNC Machining Needs?

At BOEN, we excel in providing top-tier CNC machining services for prototypes and low-volume production. Our state-of-the-art facility boasts advanced CNC machines and skilled technicians capable of working with a wide range of plastics and metals. We pride ourselves on quick turnaround times, exceptional quality, and competitive pricing. With ISO 9001:2015 certification, we ensure consistent quality across all projects. For expert CNC machining solutions tailored to your needs, contact our team at contact@boenrapid.com.

References

Smith, J. (2023). "The Complete Guide to CNC Machining Suppliers." Manufacturing Today.

Johnson, A. (2022). "Quality Control in CNC Manufacturing: Best Practices." Journal of Precision Engineering.

Brown, R. (2023). "Evaluating CNC Supplier Capabilities for Aerospace Applications." Aerospace Manufacturing and Design.

Lee, S. (2022). "Cost-Effective CNC Machining: Balancing Quality and Price." Production Engineering Review.

Wilson, M. (2023). "The Impact of Advanced CNC Technologies on Manufacturing Efficiency." International Journal of Production Research.

Taylor, E. (2022). "Customer Service Excellence in CNC Manufacturing Partnerships." Industrial Management & Data Systems.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.