Essential Qualities of a Superior CNC Prototyping Service

State-of-the-Art Equipment and Technology

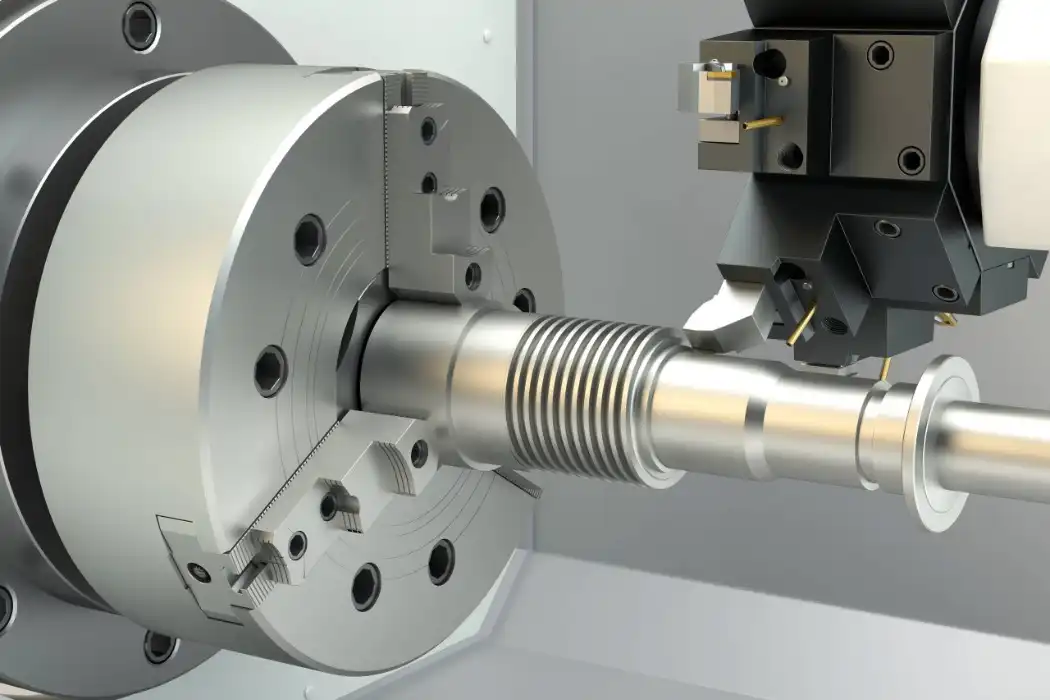

A hallmark of an exceptional CNC prototyping service is its investment in cutting-edge machinery and software. Advanced multi-axis CNC machines, equipped with the latest computer-aided manufacturing (CAM) software, enable the creation of complex geometries with unparalleled precision. These sophisticated systems allow for the efficient production of intricate parts, reducing lead times and minimizing errors. Moreover, top-tier services continually upgrade their technology to stay ahead of industry advancements, ensuring clients have access to the most innovative prototyping solutions available.

Expertise in Materials and Manufacturing Processes

Proficiency in a wide range of materials is crucial for a high-quality CNC prototyping service. From metals like aluminum and stainless steel to plastics such as ABS and polycarbonate, a comprehensive understanding of material properties and machining characteristics is essential. This knowledge enables the service provider to recommend the most suitable materials for each project, considering factors such as strength, durability, and cost-effectiveness. Furthermore, expertise in various manufacturing processes, including milling, turning, and EDM, allows for the optimal approach to be selected for each unique prototype requirement.

Rigorous Quality Control Measures

Implementing stringent quality control protocols is paramount for ensuring consistent, high-caliber prototypes. A reputable CNC prototyping service will employ advanced inspection tools, such as coordinate measuring machines (CMMs) and optical comparators, to verify dimensional accuracy and surface finish. Regular calibration of equipment and adherence to industry standards like ISO 9001 demonstrate a commitment to quality. Additionally, thorough documentation and traceability throughout the manufacturing process provide clients with confidence in the reliability and repeatability of their prototypes.

Customer-Centric Approach in CNC Prototyping Services

Collaborative Design and Engineering Support

A distinguishing feature of a superior CNC prototyping service is its willingness to engage in collaborative design and engineering processes. This involves providing valuable input on design for manufacturability (DFM), suggesting modifications to improve functionality or reduce costs, and offering alternative solutions when appropriate. By leveraging their expertise, these services can help clients optimize their designs for CNC machining, potentially saving time and resources in the long run. This collaborative approach fosters a partnership between the service provider and the client, leading to more successful outcomes and innovative solutions.

Flexible and Responsive Communication

Effective communication is the cornerstone of any successful prototyping project. A top-tier CNC prototyping service will prioritize clear, timely, and transparent communication throughout the entire process. This includes providing detailed quotes, regular project updates, and prompt responses to inquiries. Many leading services offer dedicated project managers or points of contact, ensuring clients have a consistent and knowledgeable resource for all their questions and concerns. This level of communication helps build trust, reduces misunderstandings, and allows for quick resolution of any issues that may arise during the prototyping process.

Customized Solutions and Scalability

Every prototyping project is unique, and a good CNC service recognizes the need for tailored solutions. This may involve developing custom fixtures or tooling, adapting manufacturing processes to accommodate specific design requirements, or offering a range of finishing options to achieve the desired aesthetic or functional properties. Furthermore, a forward-thinking service will consider the potential for future production needs, providing scalable solutions that can seamlessly transition from prototyping to low-volume or even mass production. This long-term perspective can save clients significant time and resources as they move their products from concept to market.

Technological Advancements and Industry Expertise in CNC Prototyping

Integration of Advanced Software and Simulation Tools

Leading CNC prototyping services leverage sophisticated software and simulation tools to enhance their capabilities and streamline the manufacturing process. Computer-aided engineering (CAE) software allows for virtual testing and optimization of designs before physical production begins, reducing the likelihood of costly errors and iterations. Finite element analysis (FEA) can be employed to predict how prototypes will perform under various stress conditions, while computational fluid dynamics (CFD) simulations can assess fluid flow characteristics for relevant applications. By integrating these advanced tools into their workflow, top-tier services can provide valuable insights and recommendations to improve prototype designs and functionality.

Specialization in Industry-Specific Requirements

A hallmark of excellence in CNC prototyping services is the ability to cater to the unique needs of various industries. Whether it's aerospace, automotive, medical devices, or consumer electronics, each sector has its own set of regulations, standards, and performance requirements. Superior prototyping services invest in developing expertise across multiple industries, understanding the nuances of each field. This specialization allows them to provide targeted solutions, ensure compliance with industry-specific standards, and offer valuable insights based on their experience with similar projects. Such industry-specific knowledge can be invaluable in navigating complex regulatory environments and accelerating time-to-market for new products.

Continuous Innovation and Process Improvement

The field of CNC prototyping is constantly evolving, with new technologies and methodologies emerging regularly. A truly outstanding service provider maintains a culture of continuous innovation and process improvement. This may involve exploring hybrid manufacturing techniques that combine CNC machining with additive manufacturing, developing proprietary tooling or fixturing solutions, or implementing lean manufacturing principles to enhance efficiency and reduce waste. By staying at the forefront of technological advancements and constantly refining their processes, these services can offer clients cutting-edge solutions and maintain a competitive edge in the rapidly changing landscape of product development and manufacturing.

Conclusion

A superior CNC prototyping service goes beyond mere machining capabilities, offering a comprehensive suite of expertise, technology, and customer-focused solutions. By combining state-of-the-art equipment, material knowledge, quality control, collaborative design support, effective communication, and industry-specific expertise, these services become invaluable partners in the product development process. As technology continues to advance, the best CNC prototyping services will adapt and innovate, providing clients with cutting-edge solutions that drive innovation and accelerate time-to-market. Choosing the right CNC prototyping service can significantly impact the success of a project, making it crucial for businesses to carefully evaluate potential partners based on these key qualities.

FAQs

What materials can be used in CNC prototyping?

CNC prototyping can work with a wide range of materials, including various metals (such as aluminum, steel, and titanium), plastics (like ABS, polycarbonate, and nylon), and even some composites. The choice of material depends on the specific requirements of the project.

How long does CNC prototyping typically take?

The turnaround time for CNC prototyping can vary depending on the complexity of the part, material used, and quantity needed. Simple parts might be completed in a few days, while more complex projects could take several weeks.

Is CNC prototyping suitable for all industries?

CNC prototyping is versatile and can be applied across numerous industries, including aerospace, automotive, medical devices, consumer electronics, and more. A good CNC prototyping service will have experience working with various sectors and their specific requirements.

Expert CNC Prototyping Services for Your Product Development Needs | BOEN

At BOEN Prototype, we specialize in delivering high-quality CNC prototyping services tailored to your unique product development requirements. As a leading supplier and manufacturer in the industry, our state-of-the-art facilities and expert team ensure precision, efficiency, and innovation in every project. From rapid prototyping to low-volume production, we're your trusted partner for bringing your ideas to life. Contact us at contact@boenrapid.com to discuss how we can support your next project.

References

Johnson, M. (2022). Advanced CNC Prototyping Techniques for Modern Manufacturing. Journal of Precision Engineering, 45(3), 287-301.

Smith, A., & Brown, B. (2021). Quality Control in CNC Prototyping: Best Practices and Emerging Technologies. International Journal of Manufacturing Research, 16(2), 112-128.

Lee, C. H., et al. (2023). The Role of Material Science in CNC Prototyping: A Comprehensive Review. Materials Today: Proceedings, 58, 1245-1260.

Wilson, D. R. (2022). Customer-Centric Approaches in CNC Prototyping Services: A Case Study Analysis. Journal of Industrial Engineering and Management, 15(1), 78-95.

Garcia, R., & Martinez, L. (2021). Integration of CAE Tools in CNC Prototyping: Enhancing Design Optimization and Validation. Computer-Aided Design and Applications, 18(4), 721-735.

Thompson, K. L. (2023). Industry-Specific CNC Prototyping: Challenges and Opportunities in Diverse Sectors. Advances in Manufacturing Technology, 7(2), 189-205.