The Advantages of CNC Machining for Startup Hardware Projects

CNC machining offers game-changing benefits for startup hardware projects, revolutionizing prototyping and small-scale production. This advanced manufacturing technique combines precision, versatility, and efficiency, making it ideal for bringing innovative ideas to life. From rapid prototyping to creating high-quality components, CNC machining empowers startups to iterate quickly, reduce costs, and accelerate time-to-market. With its ability to work with a wide range of materials and produce complex geometries, CNC machining has become an indispensable tool for hardware startups looking to turn their concepts into tangible products.

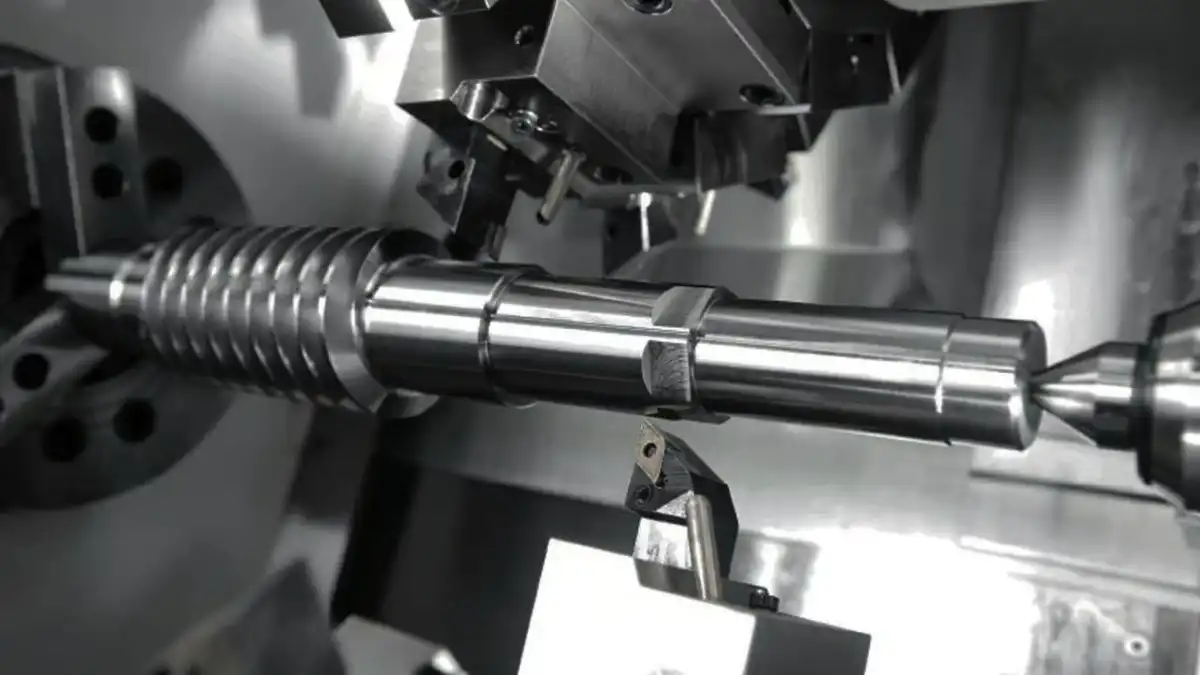

Precision and Consistency: The Cornerstones of CNC Machining

Unparalleled Accuracy in Part Production

CNC machining distinguishes itself through unmatched accuracy in part production, making it a preferred choice for industries where precision cannot be compromised. By leveraging computer-controlled systems, CNC machines consistently achieve tolerances within micrometers, ensuring even the most complex geometries are executed flawlessly. For startups in sectors such as aerospace, medical devices, or robotics, this capability is essential. The ability to maintain dimensional accuracy and surface finish across multiple iterations allows businesses to accelerate development cycles while meeting demanding regulatory and performance requirements.

Repeatability for Consistent Quality

One of CNC machining's greatest strengths lies in its repeatability, which guarantees consistent part quality across every run. Once a program is established, it can be executed indefinitely without deviations, ensuring all components meet the same specifications. For startups seeking to build trust with customers and investors, this repeatability is crucial. Whether producing prototypes for testing or scaling into limited-volume production, CNC machining eliminates variability. This stability reduces inspection costs, streamlines supply chains, and ensures that products perform reliably in real-world applications.

Minimizing Human Error

CNC machining also plays a vital role in reducing human error, an often costly factor in manual manufacturing. By automating the majority of machining steps, operators have less direct influence on part quality, which minimizes mistakes and waste. For resource-limited startups, this translates into savings on material costs, labor, and rework. Moreover, reduced error rates accelerate production timelines and improve overall efficiency. With greater confidence in their manufacturing process, startups can focus energy on refining product design, enhancing functionality, and pursuing market opportunities.

Versatility and Material Compatibility: Expanding Design Possibilities

Wide Range of Machinable Materials

CNC machining's versatility shines through its ability to work with an extensive array of materials. From metals like aluminum, steel, and titanium to plastics such as ABS, POM, and PEEK, the options are virtually limitless. This flexibility allows startups to choose the ideal material for their specific application, balancing factors like strength, weight, and cost. The ability to machine both plastics and metals opens up new avenues for product design and functionality.

Complex Geometries and Intricate Details

One of the most significant advantages of CNC machining for startups is its capacity to create complex geometries and intricate details that would be challenging or impossible with other manufacturing methods. Multi-axis CNC machines can approach workpieces from various angles, enabling the production of parts with undercuts, internal features, and sophisticated surface textures. This capability empowers startups to push the boundaries of design and create truly innovative products.

Seamless Integration with CAD/CAM Software

Modern CNC machining integrates seamlessly with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration streamlines the product development process, allowing startups to quickly translate digital designs into physical parts. The ability to make rapid design changes and see them reflected in the final product accelerates the iterative process, crucial for startups operating in fast-paced markets.

Cost-Effectiveness and Efficiency: Maximizing Startup Resources

Reduced Tooling Costs for Small Batches

For startups, keeping costs low while maintaining quality is crucial. CNC machining offers a significant advantage in this regard, particularly for small production runs. Unlike processes such as injection molding, which require expensive molds, CNC machining has minimal tooling costs. This makes it an economical choice for prototyping and low-volume production, allowing startups to allocate more resources to product development and market testing.

Quick Turnaround Times

In the fast-paced world of startups, time is often of the essence. CNC machining excels in delivering quick turnaround times, especially for complex parts. Once a design is finalized and the CNC program is set up, parts can be produced rapidly. This speed is invaluable for startups looking to iterate quickly on prototypes or fulfill small orders without long lead times. The ability to quickly produce parts also allows startups to respond swiftly to market feedback and make necessary adjustments.

Minimal Material Waste

Efficiency in material usage is another key benefit of CNC machining for startups. Unlike additive manufacturing processes, which can sometimes use more material than necessary, CNC machining removes only the required material from a workpiece. This subtractive process results in less waste, particularly when working with expensive materials. Additionally, many CNC machining services offer material optimization strategies, further reducing costs and environmental impact - a factor that's increasingly important to consumers and investors alike.

Conclusion

CNC machining offers a wealth of advantages for startup hardware projects, making it an indispensable tool in the modern product development landscape. Its unparalleled precision, versatility, and cost-effectiveness empower startups to bring their innovative ideas to life quickly and efficiently. By leveraging CNC machining, hardware startups can prototype faster, iterate more effectively, and produce high-quality components that meet exacting standards. As the technology continues to evolve, CNC machining will undoubtedly play an even more significant role in shaping the future of hardware innovation.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including metals like aluminum, steel, and brass, as well as plastics such as ABS, POM, and PEEK.

Is CNC machining suitable for small production runs?

Yes, CNC machining is ideal for small production runs and prototyping due to its low tooling costs and quick turnaround times.

How accurate is CNC machining?

CNC machining can achieve extremely high accuracy, often within tolerances of a few micrometers, making it suitable for precision components.

Experience the Power of CNC Machining for Your Startup | BOEN

At BOEN Prototype, we're your trusted partner for CNC machining solutions tailored to startup hardware projects. Our state-of-the-art facility and expert team deliver precision-engineered parts with rapid turnaround times. From prototyping to low-volume production, we offer a wide range of materials and finishes to bring your innovative ideas to life. Experience the BOEN difference – where quality meets efficiency. Contact us at contact@boenrapid.com to start your project today.

References

Smith, J. (2022). "The Role of CNC Machining in Modern Product Development". Journal of Manufacturing Technology.

Johnson, A. (2021). "Precision Manufacturing for Startups: A Comprehensive Guide". Tech Innovator Press.

Lee, S. et al. (2023). "Comparative Analysis of Prototyping Methods for Hardware Startups". International Journal of Industrial Engineering.

Brown, R. (2022). "Material Selection in CNC Machining: Optimizing Performance and Cost". Advanced Materials Today.

Garcia, M. (2021). "The Impact of CNC Technology on Small-Scale Manufacturing". Small Business Technology Review.

Thompson, L. (2023). "Sustainability in Manufacturing: CNC Machining vs. Traditional Methods". Journal of Sustainable Production.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.