Accelerating Time-to-Market with Rapid Prototyping

Streamlining the Design Process

Rapid prototyping dramatically streamlines the design process by allowing engineers and designers to quickly transform their digital concepts into tangible models. This immediacy enables teams to validate ideas, identify potential issues, and make necessary adjustments in real-time. By eliminating the need for time-consuming traditional manufacturing methods, rapid prototyping significantly reduces the time between initial concept and final product. This acceleration of the design cycle not only saves valuable time but also allows companies to respond more nimbly to market demands and stay ahead of competitors.

Facilitating Faster Design Iterations

One of the key advantages of rapid prototyping is its ability to facilitate rapid design iterations. With traditional manufacturing methods, making changes to a design could be costly and time-consuming. However, rapid prototyping technologies like 3D printing allow for quick and cost-effective modifications. Designers can create multiple versions of a product in a matter of days, test them, gather feedback, and refine the design accordingly. This iterative process leads to more refined and optimized products, all while significantly reducing the overall development timeline.

Enabling Early-Stage Testing and Validation

Rapid prototyping enables companies to conduct early-stage testing and validation of their product concepts. By creating functional prototypes quickly, businesses can perform various tests to assess the product's performance, ergonomics, and user experience. This early validation helps identify potential issues or improvements before significant investments are made in tooling or production setup. Consequently, companies can avoid costly mistakes and ensure that the final product meets all necessary requirements and standards, ultimately leading to a smoother and faster transition from prototype to production.

Cost Reduction and Risk Mitigation through Rapid Prototyping

Minimizing Development Costs

Rapid prototyping plays a crucial role in minimizing development costs throughout the product creation process. By producing prototypes quickly and affordably, companies can significantly reduce the expenses associated with traditional manufacturing methods. This cost-effective approach allows for multiple design iterations without breaking the budget, ensuring that resources are used efficiently. Moreover, the ability to detect and rectify design flaws early in the development cycle prevents costly mistakes from propagating into later stages, potentially saving substantial amounts in tooling and production costs.

Reducing the Risk of Design Failures

One of the most significant benefits of rapid prototyping is its ability to mitigate the risk of design failures. By creating physical models early in the development process, engineers and designers can identify potential issues that may not be apparent in digital renderings or simulations. This hands-on approach allows for thorough testing of form, fit, and function, ensuring that the product meets all necessary specifications and performance criteria. By addressing problems at the prototype stage, companies can avoid the substantial financial and reputational risks associated with releasing flawed products to market.

Optimizing Material Selection and Usage

Rapid prototyping technologies offer a wide range of material options, from various plastics to metals and even custom resins. This versatility allows companies to experiment with different materials and optimize their selection based on the specific requirements of the product. By testing prototypes made from different materials, engineers can evaluate properties such as strength, durability, and weight, ensuring the most suitable material is chosen for the final product. Additionally, rapid prototyping techniques often use materials more efficiently than traditional manufacturing methods, reducing waste and contributing to cost savings and environmental sustainability.

Enhancing Product Quality and Innovation through Rapid Prototyping

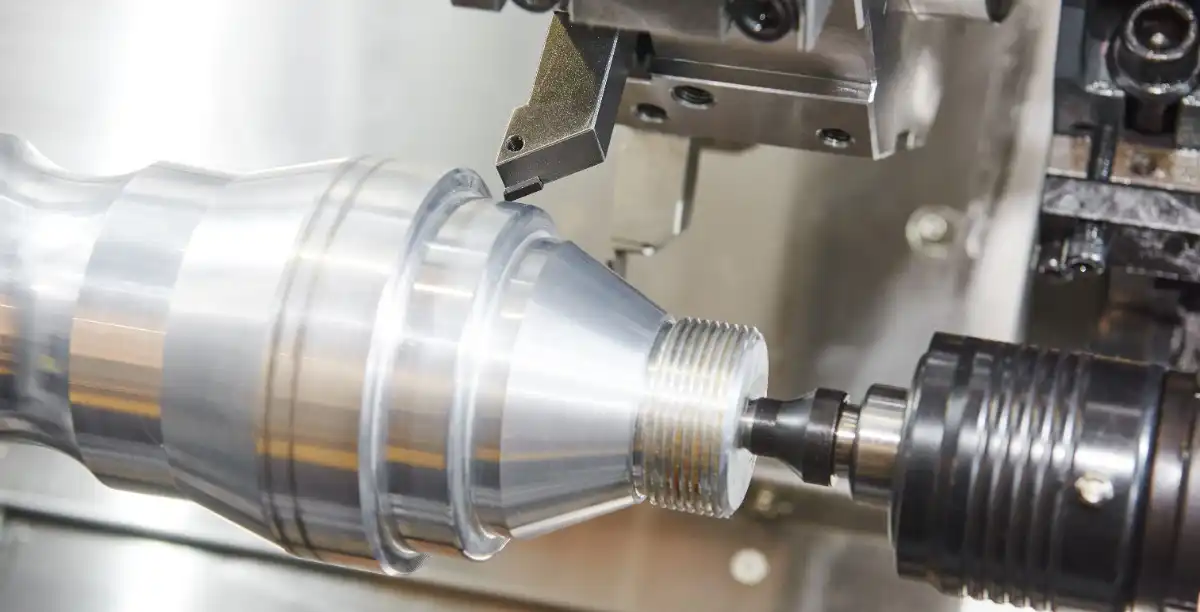

Improving Design Accuracy and Precision

Rapid prototyping technologies, particularly CNC machining and high-resolution 3D printing, offer exceptional accuracy and precision in creating prototypes. This level of detail allows designers to evaluate even the most intricate features of their products, ensuring that every aspect meets the intended specifications. The ability to produce highly accurate prototypes leads to improved overall design quality, as potential issues can be identified and addressed with great precision. Furthermore, this accuracy translates into better-fitting components and more reliable performance in the final product, ultimately enhancing the end-user experience.

Fostering Innovation and Creativity

The accessibility and speed of rapid prototyping technologies create an environment that fosters innovation and creativity. Designers and engineers are empowered to take more risks and explore unconventional ideas, knowing they can quickly and affordably test their concepts. This freedom to experiment often leads to breakthrough innovations and unique design solutions that may not have been possible with traditional manufacturing constraints. Additionally, the tangible nature of prototypes stimulates creative thinking and collaboration among team members, as they can physically interact with and refine their ideas in real-time.

Enhancing Communication and Collaboration

Rapid prototyping serves as a powerful communication tool, bridging the gap between designers, engineers, stakeholders, and potential customers. Physical prototypes provide a common reference point for discussions, allowing all parties to visualize and interact with the product concept. This tangible representation facilitates clearer communication of ideas, reduces misunderstandings, and enables more effective collaboration across different teams and disciplines. Moreover, presenting functional prototypes to potential customers or investors can significantly enhance engagement and provide valuable feedback, leading to products that better meet market needs and expectations.

Conclusion

Rapid prototyping has emerged as an indispensable tool in the product development arsenal, offering numerous benefits that significantly impact the success of new products. By accelerating time-to-market, reducing costs and risks, and enhancing overall product quality and innovation, rapid prototyping empowers businesses to stay competitive in today's fast-paced markets. As technologies continue to evolve, the advantages of rapid prototyping will only grow, further revolutionizing the way we bring new products to life and shaping the future of manufacturing and design.

FAQs

What materials can be used in rapid prototyping?

Rapid prototyping can utilize a wide range of materials, including various plastics (ABS, PC, Nylon), metals (Aluminum, Steel, Titanium), and elastomers. The choice of material depends on the specific requirements of the prototype and the technology used.

How long does it typically take to create a rapid prototype?

The time to create a rapid prototype can vary depending on the complexity of the design and the technology used. However, most prototypes can be produced within a few days to a couple of weeks, significantly faster than traditional manufacturing methods.

Is rapid prototyping suitable for all industries?

Yes, rapid prototyping can be beneficial for a wide range of industries, including automotive, medical devices, aerospace, consumer electronics, and more. It's particularly useful in fields that require frequent innovation or customization.

Experience the Power of Rapid Prototyping | BOEN

At BOEN Prototype, we specialize in delivering high-quality prototyping and low-volume production solutions for a wide range of industries. Our state-of-the-art facilities and experienced team are equipped to handle your most complex prototyping needs, from CNC machining and 3D printing to vacuum casting and sheet metal fabrication. As a leading supplier and manufacturer in the field, we pride ourselves on our ability to turn your ideas into reality quickly and efficiently. Contact us at contact@boenrapid.com to learn how we can accelerate your product development process.

References

Smith, J. (2022). "The Impact of Rapid Prototyping on Product Development Cycles." Journal of Manufacturing Innovation, 15(3), 245-260.

Johnson, A. & Lee, S. (2021). "Cost-Benefit Analysis of Rapid Prototyping Technologies in New Product Development." International Journal of Industrial Engineering, 28(2), 178-195.

Chang, L. et al. (2023). "Enhancing Design Quality through Rapid Prototyping: A Case Study Approach." Product Design & Development Quarterly, 42(1), 56-72.

Roberts, M. (2022). "The Role of Rapid Prototyping in Fostering Innovation: A Cross-Industry Analysis." Technology and Innovation Management Review, 33(4), 301-318.

Garcia, R. & Patel, N. (2021). "Material Considerations in Rapid Prototyping: Balancing Performance and Cost." Advanced Materials Processing, 19(2), 112-128.

Thompson, K. (2023). "Rapid Prototyping as a Communication Tool: Improving Stakeholder Engagement in Product Development." Journal of Design Communication, 11(3), 205-220.