Although they have certain differences, rapid prototyping and 3D printing are frequently used interchangeably. Rapid prototyping includes a wider variety of procedures and technologies than just 3D printing, while the latter is still an important subset of the former. Rapid prototyping refers to a group of techniques used to quickly fabricate a model of a physical part or assembly using three-dimensional computer aided design (CAD) data. It includes a lot of different ways to make things, like 3D printing, CNC cutting, and injection molding. So, while all 3D printing can be considered rapid prototyping, not all rapid prototyping is 3D printing.

Understanding Rapid Prototyping Technologies

The Evolution of Rapid Prototyping

Rapid prototyping has come a long way since its inception in the 1980s. Initially developed as a means to create prototypes quickly and cost-effectively, it has evolved into a sophisticated set of technologies that can produce functional parts and even end-use products. The time it takes to go from an idea to a real product has been cut down by a huge amount. This lets businesses come up with new ideas and goods faster.

Various Rapid Prototyping Techniques

While 3D printing is perhaps the most well-known rapid prototyping technique, it's far from the only one. CNC machining, for instance, uses computer-controlled cutting tools to remove material from a solid block, creating precise parts with excellent surface finishes. Injection molding, another rapid prototyping method, involves injecting molten material into a mold to create parts quickly and in high volumes. Each technique has its strengths and is suited to different applications, materials, and production volumes.

Choosing the Right Rapid Prototyping Method

Choosing the right rapid prototyping method relies on a number of things, such as the material properties you want, the number of parts you need to make, how accurate you need the measurements to be, and the surface finish you need. For example, 3D printing is great for making complicated shapes and is best for small-scale production. On the other hand, CNC milling is more accurate and can be used with many different types of materials. Businesses that want to use rapid prototyping successfully in their product development process need to understand these differences.

The Role of 3D Printing in Rapid Prototyping

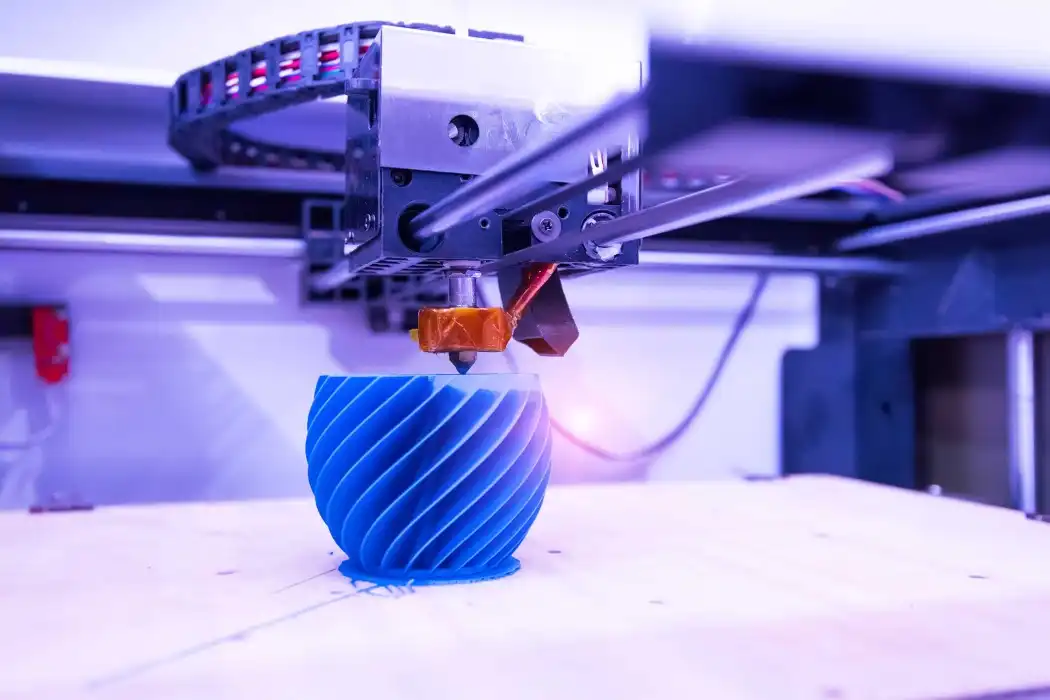

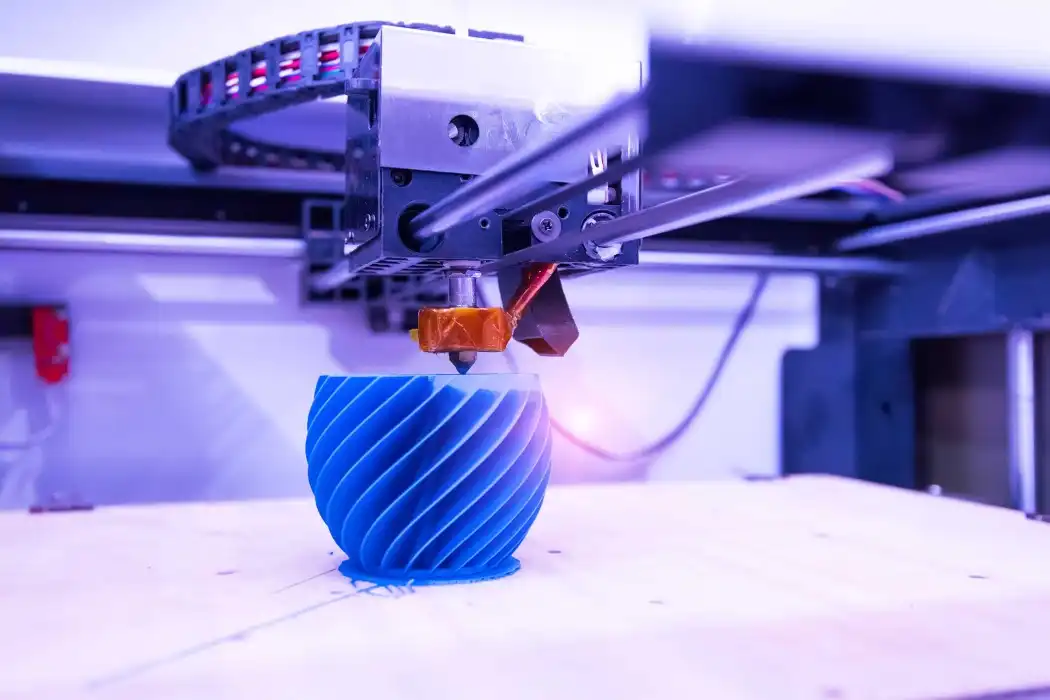

Advantages of 3D Printing

Rapid prototyping has changed a lot because of 3D printing, which is also called additive production. Due to its ability to make complex shapes that would be impossible or too expensive to make with traditional methods, it is the first choice for many businesses. Changes that were once thought to be impossible are now possible in areas like engineering and health care thanks to 3D printing. It is also very helpful when making new products because it is quick and cheap to make small amounts.

Limitations of 3D Printing

Despite its many advantages, 3D printing isn't without limitations. Material options, while expanding, are still more limited compared to traditional manufacturing methods. Finishing the surface and getting the sizes right can also be hard, especially with some 3D printing technologies. Also, when making a lot of things, 3D printing is often not as cost-effective as other methods like injection casting. Businesses need to know these limits in order to make smart choices about when and how to use 3D printing in their rapid prototyping processes.

Integrating 3D Printing with Other Rapid Prototyping Techniques

The most effective rapid prototyping strategies often involve a combination of techniques. As an example, a product might begin with a 3D-printed sample to test the idea, then move on to CNC-machined parts to make sure the product works, and finally use injection molding for test runs before it goes into production. With this unified method, companies can use the best parts of each technique at different stages of product creation, making the most of cost, time, and quality.

The Future of Rapid Prototyping and 3D Printing

Emerging Technologies in Rapid Prototyping

New ideas are born all the time in the field of rapid prototyping. It appears like new tools are being developed daily, which will further alter production methods. The development of high-performance polymers and metal alloys has expanded the range of applications for rapid prototyping. Hybrid manufacturing systems, which combine additive and subtractive techniques, are also on the rise. Methods for producing intricate, precisely engineered components are expanded by these systems.

Industry 4.0 and Rapid Prototyping

The integration of rapid prototyping with Industry 4.0 technologies is set to transform manufacturing. More intelligent and efficient manufacturing processes are being developed by combining rapid prototyping methods with digital twins, AI, and the IoT. Adaptive manufacturing using real-time data, predictive equipment maintenance, and real-time optimization of prototyping processes are all made possible by this convergence.

Sustainability in Rapid Prototyping

As sustainability becomes an increasingly important consideration in manufacturing, rapid prototyping techniques are evolving to meet these challenges. The industry is actively striving to reduce its environmental impact through the use of biodegradable materials for 3D printing and more energy-efficient CNC machines. In addition, a more sustainable manufacturing environment is being created by rapid prototyping's capacity to make parts locally and on-demand, which helps to reduce waste and emissions connected to transportation.

Conclusion

Although 3D printing plays a significant role in rapid prototyping, it's worth noting that a wider array of technologies and techniques are used in the process. Computer numerical control (CNC) machining, injection molding, and other types of 3D printing all have their own advantages and uses. Businesses can improve their product development processes, decrease time-to-market, and promote innovation by gaining a good grasp of these distinctions and using the appropriate techniques as needed. The future of production and product design will be profoundly influenced by fast prototyping technologies as they advance.

ISO-Certified Rapid Prototyping | BOEN

At BOEN Prototype, we offer more than just 3D printing solutions. As specialists in prototypes and low-volume production using both plastic and metal materials, we provide a comprehensive range of rapid prototyping services. Our cutting-edge SLA and SLS 3D printing technologies, together with our CNC machining, compression molding, rapid injection molding, metal pressing, die casting, and vacuum casting, are all part of our ISO-certified procedures that guarantee the best quality standards. When companies want to shorten the time it takes to develop a new product, they turn to BOEN as a partner because of our dedication to quick turnaround times and guaranteed quality.

Experience the BOEN difference in rapid prototyping. For more information about our services and how we can support your product development needs, contact us at contact@boenrapid.com.

References

Gibson, I., Rosen, D., & Stucker, B. (2021). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer.

Gebhardt, A. (2018). Understanding Additive Manufacturing: Rapid Prototyping, Rapid Tooling, Rapid Manufacturing. Carl Hanser Verlag GmbH & Company KG.

Kamrani, A. K., & Nasr, E. A. (2019). Rapid Prototyping: Theory and Practice. Springer.

Chua, C. K., Leong, K. F., & Lim, C. S. (2020). Rapid Prototyping: Principles and Applications. World Scientific.

Noorani, R. (2017). 3D Printing: Technology, Applications, and Selection. CRC Press.

Hopkinson, N., Hague, R., & Dickens, P. (2018). Rapid Manufacturing: An Industrial Revolution for the Digital Age. John Wiley & Sons.