3D Printing vs. CNC Machining: Differences and Comparison

Two technologies that frequently come up in discussions about manufacturing and prototyping are CNC machining and 3D printing. Their methods, materials, and applications are very different, yet both have their own set of benefits and capabilities. 3D printing, also known as additive manufacturing, builds objects layer by layer from the ground up. In contrast, CNC machining is a subtractive process that carves out parts from solid blocks of material. While 3D printing excels in creating complex geometries and rapid prototyping, CNC machining shines in precision, material versatility, and surface finish quality. Considerations like manufacturing volume, material needs, design complexity, and desired finish dictate the technology choice. In order to choose the best manufacturing process for your requirements, it is essential to understand the benefits and drawbacks of each option.

Understanding the Fundamentals: 3D Printing and CNC Machining

The Basics of 3D Printing Technology

Rapid prototyping and product development have been revolutionized by the advent of 3D printing, an innovative additive manufacturing technology. Plastics, resins, or even metals can be used in the layer-by-layer construction of items with this technology. The first step is to use specialist software to slice a digital 3D model into thin layers. The printer builds the final product layer by layer by depositing material in accordance with these blueprints.

The capacity to generate complicated geometries that would be extremely challenging, if not impossible, to do with conventional manufacturing techniques is a major benefit of 3D printing. As a result, designers can easily put their ideas through their paces using rapid prototyping. However, 3D printing can be slower for large production runs and may have limitations in terms of material strength and surface finish.

Exploring CNC Machining Techniques

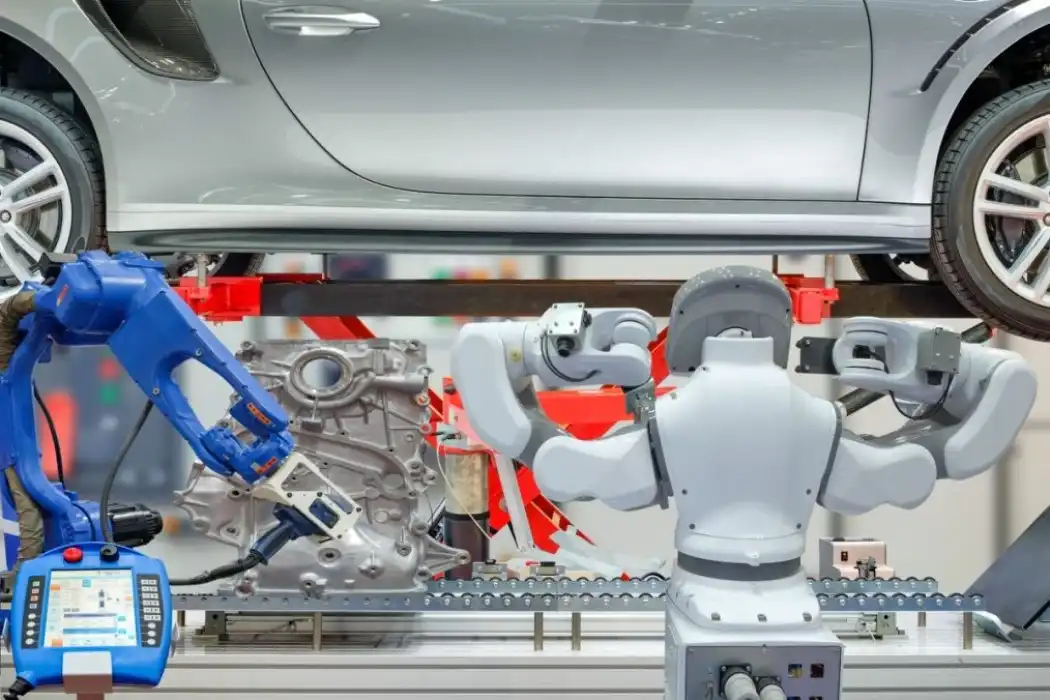

CNC machining, on the other hand, is a subtractive manufacturing process that has been a cornerstone of industrial production for decades. It involves the use of computer-controlled machines to remove material from a solid block, creating the desired shape. This process is guided by precise, pre-programmed instructions that control the movement of cutting tools.

CNC machining excels in producing parts with high precision and excellent surface finishes. It's capable of working with a wide range of materials, including metals, plastics, and composites. The technology is particularly well-suited for creating parts that require tight tolerances and consistent quality across large production runs. However, it may be less efficient for producing parts with very complex internal geometries.

Key Differences in Approach and Application

The fundamental difference between 3D printing and CNC machining lies in their approach to creating objects. 3D printing builds up material, while CNC machining removes it. This distinction leads to several key differences in their applications and capabilities.

3D printing is often preferred for creating prototypes, custom parts, and objects with complex internal structures. It's also advantageous when material waste is a concern, as it typically uses only the material needed for the part. CNC machining, conversely, is often chosen for its precision, material versatility, and ability to produce parts with excellent structural integrity. It's particularly well-suited for manufacturing functional components that require high accuracy and consistent quality.

Comparing Capabilities: Precision, Materials, and Production Scale

Precision and Accuracy in Manufacturing

When it comes to precision, CNC machining generally has the upper hand. Modern CNC machines are perfect for fabricating extremely precise items since they can reach tolerances as narrow as ±0.0001 inches. Manufacturing airplanes, automobiles, and medical devices requires this degree of accuracy because even small mistakes can have major repercussions in these fields.

3D printing, while continuously improving, typically offers lower precision compared to CNC machining. But when it comes to replicating intricate geometries and internal components, it really shines, even when conventional machining techniques fail miserably. The precision of 3D printing differs from one technology to another, however some top-tier equipment can achieve tolerances of ±0.005 inches or even better.

Material Versatility and Limitations

CNC machining boasts an impressive range of compatible materials. A wide variety of metals, polymers, woods, and composites are all within its solid material compatibility range. Because of its adaptability, CNC machining is preferred by sectors that must adhere to regulations or have materials with particular characteristics.

3D printing, while more limited in material options, has seen significant advancements in recent years. A wide range of materials, including ceramics, metals, resins, and polymers, can be fed into modern 3D printers. There is a possibility that the strength and durability of 3D printed components will be different from those of conventionally made components.

Scalability and Production Volume Considerations

When it comes to production volume, CNC machining and 3D printing have different strengths. CNC machining is highly efficient for medium to large production runs. Once the initial programming is complete, CNC machines can produce identical parts quickly and consistently, making them ideal for mass production scenarios.

3D printing, on the other hand, excels in low-volume production and customization. It's particularly advantageous for creating prototypes or small batches of specialized parts. However, as production volume increases, 3D printing can become less cost-effective compared to traditional manufacturing methods like CNC machining.

Making the Choice: Factors to Consider and Future Trends

Decision Factors: Cost, Time, and Design Complexity

Choosing between 3D printing and CNC machining involves balancing several factors. Cost considerations include not just the price per part, but also tooling expenses, material costs, and production volume. For small runs or prototypes, 3D printing often proves more economical due to its lower setup costs. However, as production volume increases, CNC machining typically becomes more cost-effective.

Time is another crucial factor. 3D printing can offer quicker turnaround for small batches or one-off parts, especially those with complex geometries. CNC machining, while potentially requiring more setup time, can be faster for larger production runs. The complexity of the design also plays a role - intricate internal structures or organic shapes might favor 3D printing, while parts requiring high precision or specific material properties might be better suited to CNC machining.

Emerging Technologies and Hybrid Solutions

The boundaries between conventional categories in manufacturing are becoming more porous as a result of new technology. More and more, businesses are looking to hybrid manufacturing solutions that combine additive and subtractive techniques. These systems have the ability to combine the best features of 3D printing with CNC machining, which opens up new avenues for improving manufacturing efficiency and designing parts.

Both technologies are seeing their powers enhanced by developments in materials science. This encompasses the creation of novel metal alloys and high-performance polymers for use in 3D printing. Cutting tool and machining strategy advancements in computer numerical control (CNC) machining are allowing for even more efficiency and accuracy.

Industry-Specific Applications and Case Studies

Different industries leverage 3D printing and CNC machining in unique ways. While CNC machining is still essential for producing highly accurate, structurally important components, 3D printing is changing the game when it comes to producing lightweight, complicated components for the aerospace industry. The medical industry uses both technologies - 3D printing for custom implants and prosthetics, and CNC machining for surgical instruments and medical devices requiring strict tolerances.

The production of engine components and other precision parts in the automobile sector is still dominated by CNC machining. But quick prototyping and the construction of complicated, lightweight structures are two areas where 3D printing is finding more and more applications. The specific needs of each project and business dictate the choice between CNC machining and 3D printing, as shown by these examples from different industries.

Conclusion

It is clear from comparing CNC machining with 3D printing that each technology excels at what it does best. 3D printing shines in rapid prototyping, complicated geometries, and customization, whereas CNC machining delivers superior precision, material diversity, and efficiency in bigger production runs. Design complexity, material requirements, production volume, cost, and other project-specific factors will determine which of these approaches is best as manufacturing technology advance. In today's complex manufacturing scene, it is essential to have a good grasp of the advantages and disadvantages of 3D printing and CNC machining.

FAQ

When should I choose CNC machining over 3D printing?

Choose CNC machining when you need high precision, excellent surface finish, or parts made from strong metals and engineering-grade plastics. It’s ideal for functional parts, tight tolerances, and medium to large production runs.

What materials can be used in CNC machining?

CNC machining supports a wide variety of materials including aluminum, steel, titanium, brass, ABS, POM, nylon, and composite plastics. This versatility makes it suitable for applications in aerospace, automotive, medical, and more.

Is CNC machining suitable for prototyping?

Yes, CNC machining is widely used for prototyping, especially when the prototype must function like the final product. It ensures accurate dimensions and material properties, making it ideal for performance testing and validation.

High-Precision CNC Machining for Rapid Prototyping | BOEN

At BOEN, we specialize in high-precision CNC machining for rapid prototyping and low-volume production. We can manufacture complicated components with pinpoint precision and mirror-like surface finishes thanks to our state-of-the-art CNC technology. To guarantee that every component is precisely according to plan, we optimize machine parameters, cutting time, and fine-tuning tolerances with state-of-the-art programming tools.

Making prototypes is simply the tip of the iceberg when it comes to CNC machining. Plastic injection molding and pressure die casting are among the procedures via which we produce tools. Our cutting-edge machinery allows us to process a broad variety of materials, including metals and plastics, giving us the flexibility to satisfy the demands of a wide range of industries. For more information about our CNC machining services and how we can support your product development needs, please contact us at contact@boenrapid.com.

References

Gibson, I., Rosen, D., & Stucker, B. (2015). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer.

Groover, M. P. (2020). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons.

Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T., & Hui, D. (2018). Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering, 143, 172-196.

Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson.

Thompson, M. K., Moroni, G., Vaneker, T., Fadel, G., Campbell, R. I., Gibson, I., ... & Martina, F. (2016). Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP annals, 65(2), 737-760.

Yao, X., Moon, S. K., & Bi, G. (2017). A hybrid machine learning approach for additive manufacturing design feature recommendation. Rapid Prototyping Journal.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.