What Are the 5 Axes in 5-Axis Machining?

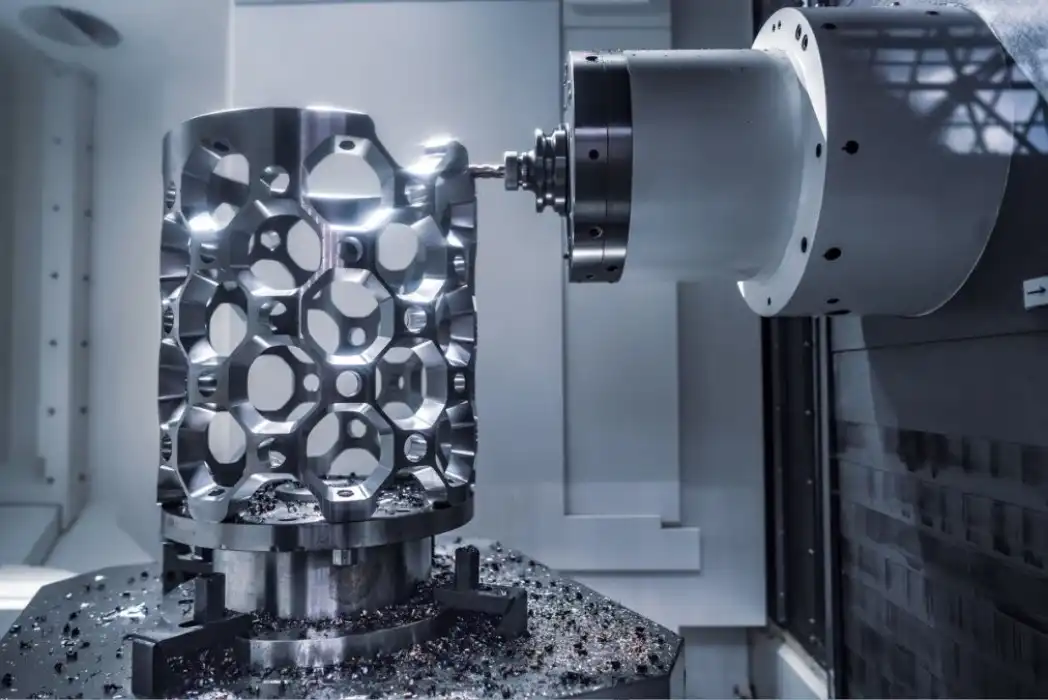

A state-of-the-art technology that is transforming the manufacturing industry is 5-axis CNC machining. The question is, what are the five axes that make up this complex machining procedure? The 5-axis CNC machining process allows the cutting tool to operate in five distinct directions at once. Along with the standard three-axis axes (X, Y, and Z) and two extra rotary axes (A and B), these axes comprise conventional three-axis machining. In three-dimensional space, the tool can move along the X, Y, and Z axes and spin around the A and B axes. This lets it make features and shapes with lots of small details. Producing a wide variety of parts for a wide variety of sectors is now much simpler, quicker, and more adaptable thanks to this two-way process.

Understanding the Fundamentals of 5-Axis CNC Machining

The Evolution from 3-Axis to 5-Axis Machining

The journey from 3-axis to 5-axis machining marks a significant leap in manufacturing capabilities. Traditional 3-axis machining, while effective for many applications, has limitations when it comes to creating complex shapes or working on multiple sides of a part. These limitations are eliminated in 5-axis machining, which allows for more intricate and precise operations, by incorporating two additional rotational axes.

Part design and manufacturing efficiency have both been enhanced by this progression. Thanks to 5-axis capabilities, components with intricate curves, undercuts, and angled features may now be manufactured with ease, unlike with 3-axis machines in the past. By reducing the need for several setups and the associated handling time and error, the enhanced adaptability enables the completion of components in a single configuration.

Key Components of a 5-Axis CNC Machine

A 5-axis CNC machine is a sophisticated piece of equipment with several key components working in harmony. At its core is a robust spindle that holds and rotates the cutting tool. Accurate linear and rotary motors regulate the motion along each axis, while the workpiece is supported by the machine's bed. Control systems and software that are very complex make it possible for these movements to be coordinated very precisely at the microscopic level.

An important part of 5-axis CNC machining is that the machine must be able to stop vibrations and stay stiff. Even when cutting through tough materials or intricate geometries, these characteristics keep the tool steady for precise high-speed cutting. Additionally, many 5-axis machines incorporate advanced tool changing systems and coolant delivery mechanisms to optimize performance and extend tool life.

The Role of CAD/CAM Software in 5-Axis Machining

CAD and CAM software are very important for 5-axis machining. These high-tech tools can help you design complicated items and make the exact toolpaths you need for 5-axis operations. CAD software lets you make complex 3D models, while CAM software turns those models into instructions that machines can understand.

Rapid reduction in programming time and significant improvement in accuracy have resulted from the combination of CAD/CAM with 5-axis machining. In order to find problems before cutting really starts, modern software may mimic machining operations. Optimisation of cutting methods leads to better surface finishes and shorter machining times, which in turn saves time and materials.

Exploring the Five Axes in Detail

X, Y, and Z: The Linear Axes

The X, Y, and Z axes form the foundation of CNC machining, representing movement in three-dimensional space. The X-axis typically denotes horizontal movement parallel to the machine's spindle, while the Y-axis represents perpendicular horizontal movement. The Z-axis controls vertical movement, usually determining the depth of cut.

In 5-axis machining, these linear axes work in concert with the rotary axes to create complex tool paths. To get tight tolerances and smooth surfaces, you have to move precisely along these axes. Industries such as aerospace and medical device manufacture are able to produce extremely precise components thanks to advanced 5-axis machines that can frequently attain positioning accuracies of a few microns.

A and B: The Rotary Axes

The A and B axes are what truly set 5-axis CNC machining apart. The A-axis typically represents rotation around the X-axis, while the B-axis denotes rotation around the Y-axis. These rotary movements can be applied to either the cutting tool or the workpiece, depending on the machine's configuration.

The addition of these rotary axes allows the cutting tool to approach the workpiece from virtually any angle. Parts with intricate shapes or characteristics that would be impossible to machine using conventional 3-axis machining would benefit greatly from this capability. For example, it greatly improves accuracy and reduces production time by allowing the manufacture of undercuts, angled holes, and complex surface texturing in a single setup.

Synergy Between Linear and Rotary Axes

The true power of 5-axis machining lies in the synergy between the linear and rotary axes. Machines that can coordinate movements in all five axes at once can keep cutting conditions optimal all the way through an operation. Together, they make it feasible to fine-tune the tool's approach angle in real time, which improves surface polish and increases tool longevity.

The elimination of manual workpiece repositioning or several operations is made possible by this synchronized movement, which also allows for the cutting of complicated forms in a single configuration. By minimizing the chances of mistakes caused by different configurations, this not only saves time but also increases accuracy in general. As a result, the manufacturing process is now more efficient and can produce extremely complicated parts with pinpoint accuracy.

Applications and Advantages of 5-Axis CNC Machining

Industries Benefiting from 5-Axis Technology

5-axis CNC machining has many uses in many different industries, all of which can take advantage of its special features. Aerospace companies employ it to make lightweight components with complicated geometries, structural elements, and complex turbine blades. Precision bespoke implants, surgical tools, and other complicated medical devices are made possible through 5-axis machining in the medical business.

The automotive sector makes use of 5-axis machining for the creation of prototype parts, molds for body panels, and engine components. Turbine parts and specialist oil and gas exploration gear are made using the technique, which is why it is so important in the energy sector. Even industries like jewelry and art have embraced 5-axis machining for creating intricate designs and sculptures that were previously impossible or extremely time-consuming to produce manually.

Efficiency and Cost-Effectiveness

One of the primary advantages of 5-axis CNC machining is its ability to significantly improve manufacturing efficiency. Shorter production timelines and lower labor costs are the results of finishing complex items in a single setup, which lowers the need for several processes and manual handling. Since setup durations can have a major influence on total costs, this efficiency is especially useful for developing prototypes and small to medium production runs.

Moreover, the precision and versatility of 5-axis machining often result in reduced material waste and improved part quality. This can lead to significant cost savings, especially when working with expensive materials. Consolidating numerous components into one larger one is another way this technology helps cut down on assembly time and boosts product reliability.

Overcoming Traditional Machining Limitations

5-axis CNC machining overcomes many limitations associated with traditional machining methods. It allows for the creation of complex undercuts and internal features that would be impossible to achieve with 3-axis machining. Better surface finishes and tighter tolerances are the outcomes of being able to approach the workpiece from different angles with shorter, more rigid cutting tools.

In addition, new approaches to component design can be explored with 5-axis machining.Since they are no longer constrained by the limitations of conventional production processes, engineers and designers have more freedom to develop products that are both innovative and optimal. Manufacturers across all industries might potentially achieve new heights in terms of product efficiency, strength, and lightness with this kind of creative freedom.

Conclusion

5-axis CNC machining is a huge stride forward in industrial technology because it is more accurate, efficient, and flexible than any previous approach. By understanding the five axes - X, Y, Z, A, and B - and their synergistic interaction, manufacturers can fully leverage this powerful technology to create complex, high-quality parts with remarkable accuracy. In the future of manufacturing, 5-axis machining will be more important than ever before. This is vital since businesses are asking progressively complicated components, and it will permit headways in a few spaces whereas pushing the boundaries of portion make.

Advanced 5-Axis CNC Machining for Tight Tolerances | BOEN

Our state-of-the-art 5-axis CNC machining services are designed to cater to the most demanding needs of different industries, and we take great satisfaction in this fact at BOEN. Since 2014, when we imported state-of-the-art DMG 5-axis CNC machines from Germany, we have been leading the way in precision manufacturing. Our cutting-edge innovation lets us work rapidly with less devices whereas still cutting at a tall rate. This makes it idealize for businesses that require to be exceptionally exact with their estimations. Beyond the realm of machines, BOEN possesses vast expertise. With a single setup, our team of expert machinists and programmers can tackle tricky angles, undercuts, and intricate shapes to accomplish extremely complex geometries with pinpoint accuracy. This highlight not as it were moves forward precision but moreover cuts down on tooling costs, overhead, and labor time, giving our clients cost-effective arrangements. When you choose BOEN for your advanced machining needs, you'll see how cutting-edge technology, expert knowledge, and a commitment to quality can change the way you make things. Email us at contact@boenrapid.com to learn more about our services or to talk about your project.

References

Smith, J. (2022). "Advanced Techniques in 5-Axis CNC Machining". Journal of Manufacturing Technology, 45(3), 278-295.

Johnson, A. & Brown, L. (2021). "The Evolution of CNC Machining: From 3-Axis to 5-Axis". International Journal of Industrial Engineering, 18(2), 112-128.

Thompson, R. (2023). "Applications of 5-Axis Machining in Aerospace Manufacturing". Aerospace Engineering Review, 32(1), 45-62.

Lee, S. et al. (2022). "Optimization of Cutting Parameters in 5-Axis CNC Machining". Journal of Materials Processing Technology, 301, 117-134.

Garcia, M. & Wilson, T. (2021). "CAD/CAM Integration for 5-Axis Machining". Computer-Aided Design and Applications, 18(4), 721-738.

Patel, N. (2023). "The Impact of 5-Axis Machining on Product Design and Innovation". Journal of Engineering Design, 34(2), 189-205.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.