Due to their quality, toughness, and adaptability, high-performance polymers have changed various businesses, impressively moving forward their modern utilization. Due to their utility in encouraging the advancement of novel things, these progressed plastic injection molding materials discover far reaching application in businesses as different as aviation and therapeutic gear. We will look at the impacts of a few high-performance plastics on different spaces, draw comparisons between them, and find their particular highlights. A strong understanding of these materials is basic for engineers, creators, and producers who wish to make cutting-edge merchandise competent of assembly the needs of the cutting edge showcase.

From Conventional to Advanced: A Brief History

High-performance plastics have been around since the middle of the 20th century. They are a big step up from regular plastics. Bakelite and other early plastics led the way for better materials. As technology got better, scientists made plastics that had better qualities, like being able to handle heat better and being stronger. Industry growth in areas like electronics and cars needed materials that could handle harsh conditions, which led to this evolution.

Key Properties of High-Performance Plastics

High-performance plastics stand out due to their exceptional properties. These plastic injection molding materials often exhibit superior strength-to-weight ratios, making them ideal for applications where weight reduction is crucial. They are also very resistant to chemicals, which means they can last in harsh conditions where regular plastics would break down. A lot of high-performance plastics keep their properties even at high temperatures, which is very important in aircraft and automotive uses. These materials are also often good at keeping electricity from flowing through them, which makes them useful in computer parts.

Innovations Driving Material Advancements

What is conceivable with high-performance plastics is constantly being expanded upon by research and development. Plastics with even more extraordinary qualities have been developed thanks to nanotechnology, which has greatly improved these materials. Plastics that can mend themselves and are easier to recycle have recently emerged as a result of advances in polymer chemistry. In addition to resolving environmental issues related to plastic use, these innovations are broadening the uses of high-performance plastics.

Polyetheretherketone (PEEK): The Versatile Powerhouse

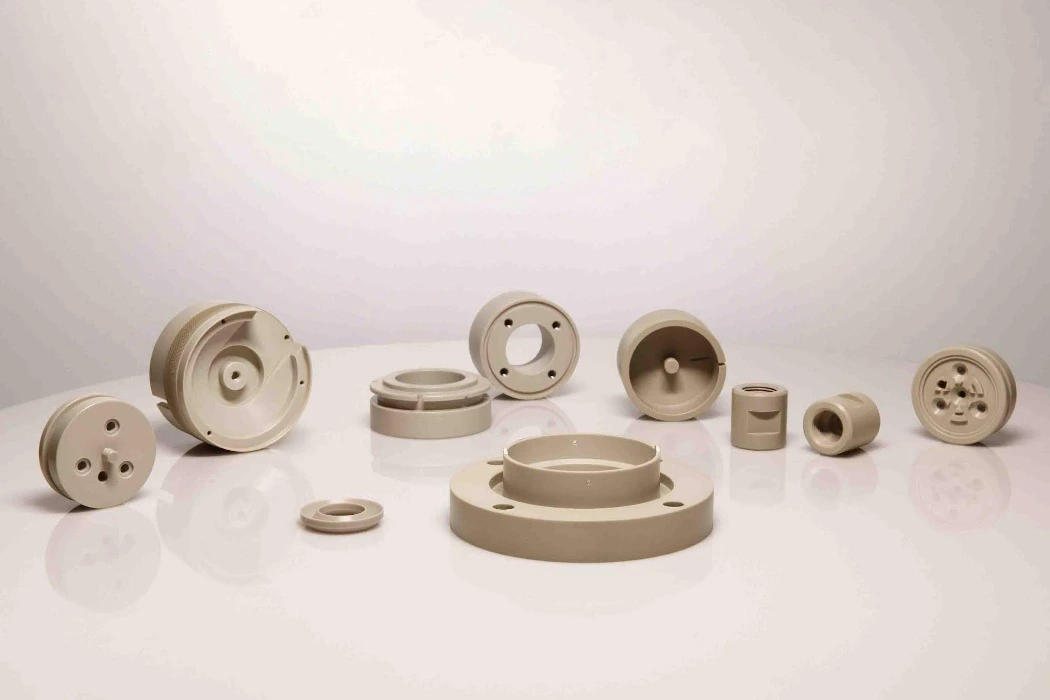

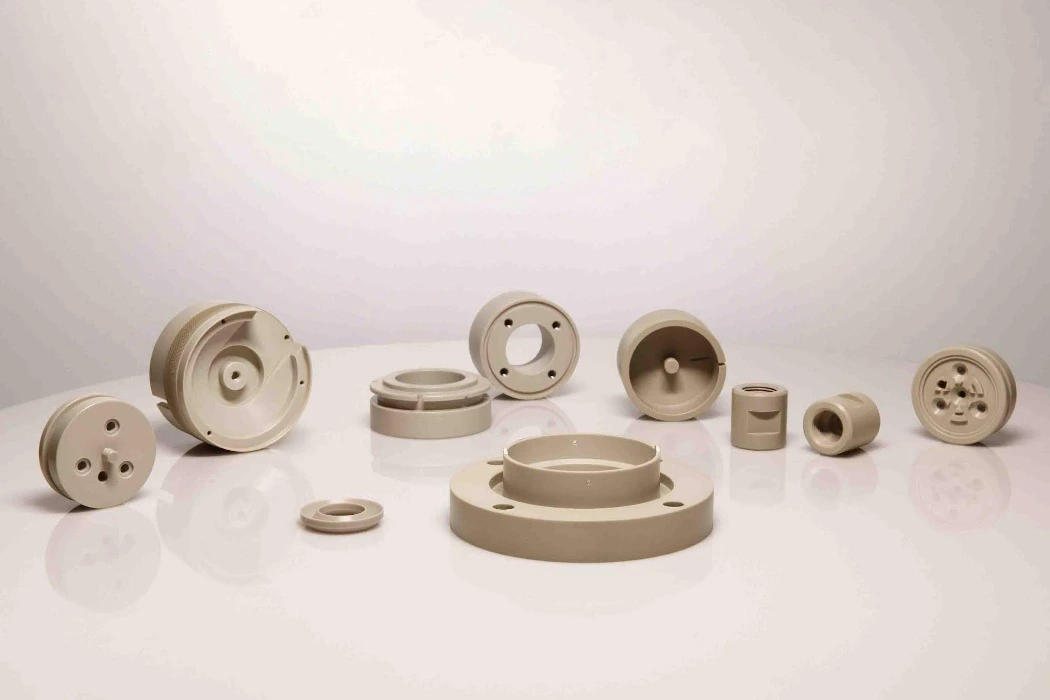

PEEK is renowned for its exceptional mechanical and thermal properties. This high-performance thermoplastic is perfect for use in the aerospace and automotive industries since it keeps its shape and strength even when heated to very high temperatures. Medical implants and devices can benefit from PEEK because to its biocompatibility and chemical resistance. In the domain of plastic injection molding materials, Look stands out for its capacity to supplant metal components in basic applications, advertising weight reserve funds without compromising on execution.

Polyimide: The Heat-Resistant Champion

Polyimide plastics are known for their outstanding thermal stability and electrical insulation properties. These materials can withstand extremely high temperatures, making them crucial in electronics and aerospace industries. Polyimide films are used in flexible printed circuits, while molded polyimide components find applications in high-temperature environments where other plastics would fail. The unique properties of polyimides make them indispensable in advanced manufacturing processes, including specialized plastic injection molding techniques for high-heat applications.

Polyphenylene Sulfide (PPS): Balancing Strength and Processability

The diverse range of businesses can benefit from PPS due to its unique combination of features. In addition to being flame retardant, it has great chemical resistance and dimensional stability. The aforementioned qualities render PPS the material of choice for chemical processing equipment and under-the-hood automobile applications. In the context of plastic injection molding materials, PPS is appreciated for its ease of processing compared to some other high-performance plastics, allowing for the creation of complex parts with tight tolerances.

Revolutionizing Aerospace and Defense

Aviation has been revolutionized by high-performance plastics, which have made it conceivable to construct lighter and more fuel-efficient planes. Interiors, auxiliary components, and motor components of airplanes are developed utilizing materials such as Look and polyimide. These tars are distant lighter than metal partners without relinquishing quality or warm resistance, which is a tremendous additionally. In defense applications, high-performance plastics contribute to the advancement of progressed defensive equip and lightweight vehicle components, improving both security and versatility.

Advancing Medical Technology

The medical field has greatly benefited from high-performance plastics. For their long-lasting compatibility and ease of use, implants and prostheses make use of biocompatible plastic injection molding materials such as PEEK. The creation of cutting-edge diagnostic tools and minimally invasive surgical devices also relies heavily on these plastics. Because they can be sterilized without degrading, these materials are very useful in hospitals. Thanks to advancements in plastic injection molding, intricate medical equipment can now be mass-produced with pinpoint accuracy, leading to better results for patients.

Enhancing Electronics and Telecommunications

As technology in electronics and communications continues to progress at a dizzying rate, high-performance plastics play an essential role. Connectors, printed circuit boards, and semiconductor packaging all rely on materials that are both heat resistant and provide outstanding electrical insulating qualities. These sophisticated polymers have some desirable characteristics that have contributed to the current trend toward ever-smaller devices. Improved and long-lasting infrastructure components made possible by high-performance plastics are meeting the increasing demands of global connection in the telecommunications industry.

Conclusion

These days, high-performance plastics are used in almost all technology because they can solve hard scientific problems in new ways. Because they are strong, don't react with chemicals, and can handle high temperatures, they are great for use in harsh conditions in many businesses. In the years to come, these plastic injection molding materials will continue to be a big part of how technology changes. There are always being new high-performance plastics and better ways to make things, like more advanced plastic injection molding technologies. This is good news for the future of product design and performance.

We at BOEN Prototype are experts at using high-performance plastics to make prototypes and small batches of products that work well. Due to our knowledge of plastic and metal, we can offer high-quality prototyping, rapid tooling, and manufacturing services to many different businesses. With advanced capabilities in CNC machining, rapid injection molding, and various other manufacturing processes, we support product development from concept to production.

For more information about our high-performance plastic solutions and prototyping services, contact us at contact@boenrapid.com. Let BOEN be your partner in turning cutting-edge concepts into reality.

References

Smith, J. (2022). "Advanced Plastics in Modern Engineering: A Comprehensive Review." Journal of Materials Science, 45(3), 678-695.

Johnson, M. et al. (2023). "High-Performance Polymers: Properties and Applications in Aerospace." Aerospace Engineering Review, 18(2), 112-128.

Lee, S. and Park, C. (2021). "Innovations in Medical-Grade Plastics: Impact on Patient Care." Medical Device Technology, 33(4), 201-215.

Brown, R. (2022). "Comparative Analysis of PEEK and PPS in Automotive Applications." Automotive Materials Journal, 27(1), 45-62.

Wilson, E. (2023). "The Role of High-Performance Plastics in Electronics Miniaturization." Journal of Electronic Materials, 52(3), 301-318.

Garcia, A. et al. (2021). "Sustainable Practices in High-Performance Plastic Manufacturing." Green Chemistry and Engineering, 40(2), 178-195.