Utilizing CNC machining on aluminum has changed the production industry because it is both very strong and very light. This material can be used in a lot of different ways and is now standard in many fields. When it comes to CNC cutting, aluminum has many benefits, such as being easy to work with, resistant to corrosion, and inexpensive. As we go more profound into this point, we will look at how aluminum CNC parts have risen as a pivotal component of modern fabricating, catering to the thorough prerequisites of businesses such as shopper hardware, flying, and automobiles.Unparalleled Properties of Aluminum for CNC Machining

Key Material Benefits of Aluminum for CNC Machining

Exceptional Machinability

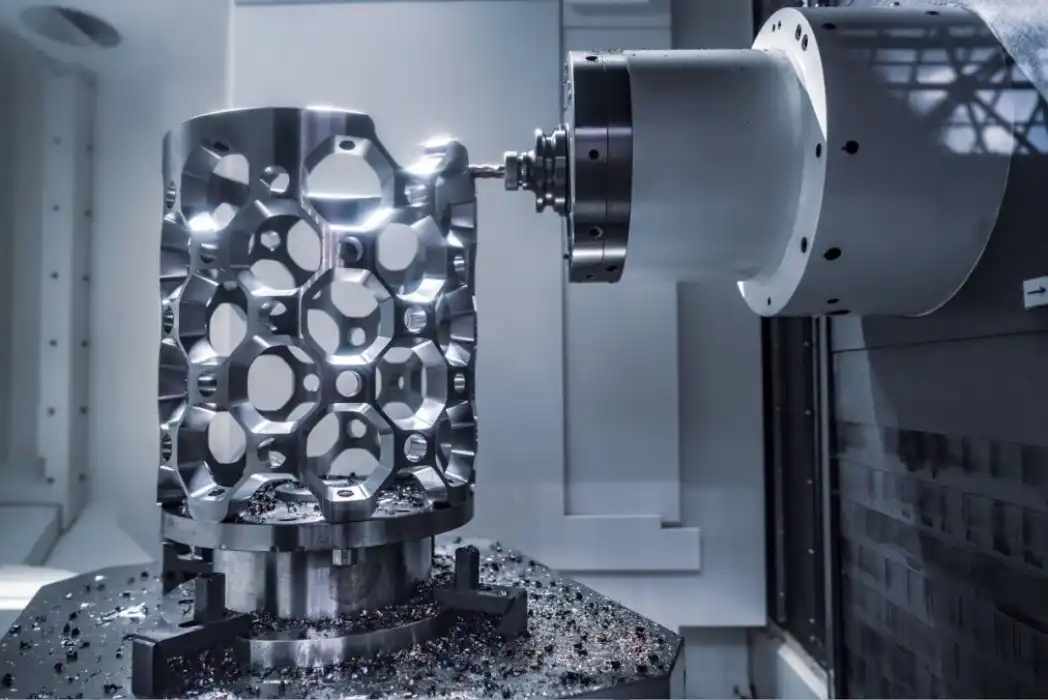

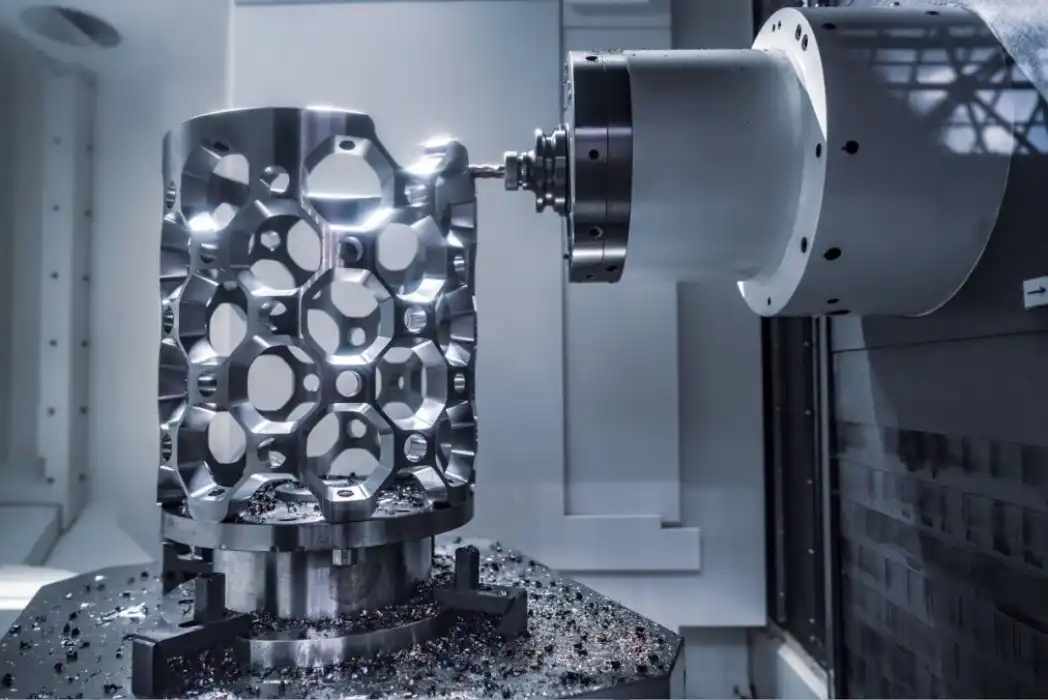

Aluminum's soft nature makes it highly machinable, allowing for intricate designs and precise cuts. This feature allows for the effortless creation of complex geometries by manufacturers, which in turn reduces production time and costs. Longer tool life and reduced cutting force needs are two additional benefits of this material that contribute to improved CNC efficiency.

Strength-to-Weight Ratio

The remarkable strength-to-weight ratio of aluminum is one of the most attractive features of this material when it comes to CNC machining. Because of this quality, aluminum CNC parts are perfect for uses where reducing weight is of the utmost importance without sacrificing structural integrity. Because it enables the fabrication of lightweight yet strong components, this feature is tremendously advantageous to industries such as aerospace and automotive.

Thermal Conductivity

There are numerous uses for aluminum because of its high thermal conductivity. Electronics and heat sink production benefit from CNC-machined aluminum components because of their excellent heat dissipation properties. This quality aids in keeping temperatures constant and decreases thermal expansion problems, both of which lead to better stability while milling.

Versatility and Applications of Aluminum CNC Parts

Aerospace and Defense

The aerospace and defense industries depend extensively on aluminum CNC machining to produce mission-critical components. A plane's fuselage, satellite assembly, and frames are all made of aluminum because of its high strength-to-weight ratio. Without sacrificing structural integrity, its lightweight nature improves fuel efficiency and boosts payload capacity. CNC machining ensures the tight tolerances and consistent quality demanded by aerospace standards. Moreover, aluminum’s corrosion resistance and ability to perform under extreme conditions make it indispensable for both commercial aviation and military defense applications.

Automotive Innovation

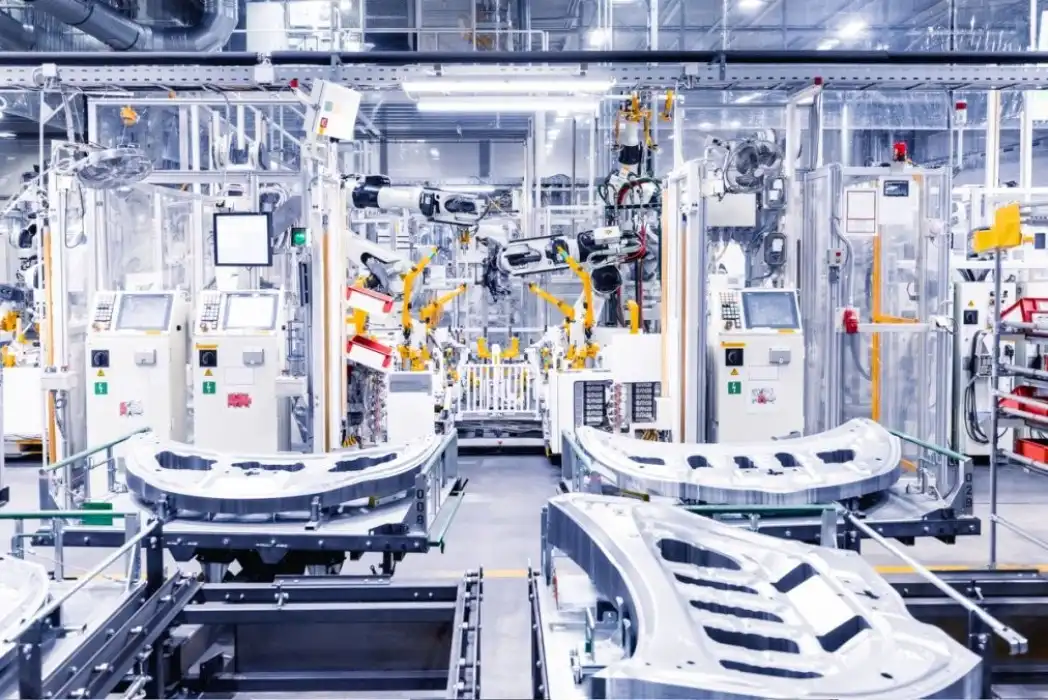

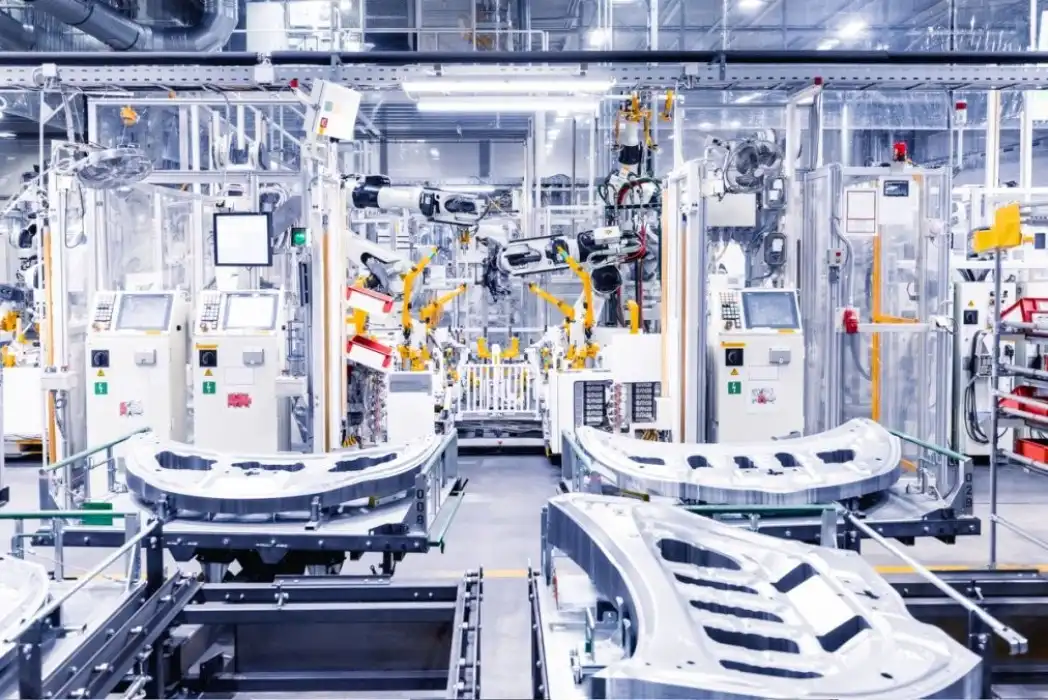

In the evolving automotive industry, aluminum CNC parts are essential for producing lightweight, high-performance components. Lots of different parts of engines, including blocks, cylinder heads, gearbox housings, and suspension systems, make use of this material. The machinability of aluminum enables the efficient mass fabrication of complicated geometries. Cutting edge car plan points for progressed fuel productivity and diminished emanations, and these lightweight components offer assistance accomplish that objective by decreasing the vehicle's by and large weight. In terms of thermal management and structural performance, CNC-machined aluminum components are becoming more important in electric vehicles.

Medical Device Manufacturing

Aluminum CNC machining supports the medical field by enabling the creation of highly precise, biocompatible, and lightweight components. Surgical tools, diagnostic equipment parts, and imaging machine housings are often machined from aluminum due to its durability and ability to withstand repeated sterilization. Because of their light weight, medical gadgets made of aluminum are easier to transport and use in hectic healthcare settings. Because of its CNC precision, aluminum is a popular material for both disposable and reusable medical equipment because it meets all of the stringent medical criteria.

Economic and Environmental Benefits of Aluminum CNC Machining

Cost-Effectiveness

Aluminum CNC machining delivers excellent cost-effectiveness due to both the material’s natural abundance and its favorable machining characteristics. Because of its low hardness, aluminum allows for higher cutting speeds with less tool wear, which in turn reduces manufacturing costs. In addition to reducing the need for surface treatments and maintenance, aluminum's corrosion resistance increases the lifespan of components. Because of these merits, aluminum is a viable and cost-effective option for sectors that need high-performance components but cannot afford to pay exorbitant amounts for their production or maintenance.

Sustainability and Recyclability

Aluminum is one of the most sustainable materials used in CNC machining, thanks to its remarkable recyclability. CNC-machined aluminum components, including aluminum CNC parts, can be reprocessed without losing material integrity, supporting circular manufacturing models. The recycling process for aluminum requires only a fraction of the energy needed to produce new metal, significantly reducing environmental impact. Aluminum is a extraordinary fabric for makers who are attempting to fulfill more exacting natural targets without relinquishing execution or quality since of this. Its environmental profile lends credence to ecologically sound manufacturing procedures in a variety of sectors.

Energy Efficiency in Production

Aluminum’s relatively low hardness and density make it easier and faster to machine than metals like steel or titanium. Because of this, tool loads are minimized and machining times are shortened, leading to lower energy consumption per part. The production process leaves less of an environmental imprint because to the energy reductions, which also lower operational expenses. Aligning manufacturing with modern energy saving and sustainability goals, manufacturers reap financial and environmental benefits by CNC machining aluminum.

Conclusion

The advantages of aluminum in CNC machining are clear and numerous. Metals like aluminum stay prevalent among makers all over the globe due to its numerous valuable properties, such as its tall strength-to-weight proportion, flexibility to distinctive applications, and ease of machining. Aluminum CNC parts already play a significant role in fostering innovation and efficiency, and their impact will only increase as technology progresses and sustainability takes center stage. Manufacturers can design goods that match the expectations of modern industries while being environmentally responsible, cost-effective, and of high quality by utilizing these advantages.

High-Speed CNC for Lightweight Aluminum Parts | BOEN

With unmatched experience in both prototypes and low-volume manufacturing, BOEN Prototype focuses on high-speed CNC machining of lightweight aluminum components. Complex aluminum components can be efficiently and precisely manufactured by us using our cutting-edge CNC technology. We are pleased of our capacity to give a few markets with high-quality components. The customer gadgets, healthcare, mechanical autonomy, and car businesses are all portion of this category. Our team's broad information of materials and coordinates generation forms permits us to handle indeed the most challenging assignments with imaginative arrangements. With BOEN, you can expect rapid turnaround times, guaranteed quality, and a commitment to meeting your unique product development needs. Send an email to contact@boenrapid.com if you would like further details regarding the CNC machining services we offer for aluminum.

References

Smith, J. (2022). "Advancements in Aluminum CNC Machining Techniques." Journal of Manufacturing Technology, 45(3), 178-192.

Garcia, M., & Johnson, L. (2021). "Comparative Analysis of Aluminum Alloys in Aerospace Applications." Aerospace Engineering Review, 33(2), 245-260.

Thompson, R. (2023). "Sustainability in Manufacturing: The Role of Recyclable Materials." Green Technology & Production, 18(4), 412-428.

Liu, Y., et al. (2022). "Optimization of CNC Machining Parameters for Aluminum Components." International Journal of Precision Engineering and Manufacturing, 23(5), 721-736.

Anderson, K. (2021). "The Impact of Lightweight Materials on Automotive Fuel Efficiency." Automotive Engineering Digest, 29(1), 55-70.

Patel, S., & Brown, D. (2023). "Innovations in Medical Device Manufacturing: The Aluminum Advantage." Medical Technology Review, 40(3), 302-318.