In the realm of manufacturing, achieving injection-molding quality for low volume manufacturing and production has long been a challenge. A new player in town, Digital Light Processing (DLP) is changing everything. While conventional injection molding requires expensive and time-consuming mold creation, this cutting-edge 3D printing technology enables manufacturers to create small batches of components with the same level of accuracy and polish. Direct Light Processing (DLP) technology paves the way for new possibilities in prototyping, custom production, and short-run manufacturing by using light to cure photopolymer resins in layers.

The Evolution of Low Volume Manufacturing

Traditional Methods vs. Modern Approaches

Low volume manufacturing has come a long way from its humble beginnings. In the past, producing small quantities of parts often meant sacrificing quality or paying exorbitant prices for tooling. Traditional methods like machining or injection molding were either too time-consuming or cost-prohibitive for small runs. However, the landscape has shifted dramatically with the advent of additive manufacturing technologies.

The Rise of 3D Printing in Production

3D printing has developed as a reasonable arrangement for low volume manufacturing and generation, advertising adaptability and cost-effectiveness. Direct Light Processing (DLP) is one of the most notable 3D printing methods because of the high level of detail and smoothness it can achieve in printed components. Industries where accuracy and individualization are of the utmost importance, such as the automobile and medical device sectors, have discovered uses for this technology.

Bridging the Gap Between Prototyping and Mass Production

DLP technology serves as a bridge between prototyping and mass production. Without investing in costly tooling, businesses may verify designs, gauge market acceptance, and even complete small orders. In today's fast-paced industry, when product lifecycles are getting shorter and customization is becoming more and more important, this flexibility is very valuable.

Understanding DLP Technology in Manufacturing

The Science Behind Digital Light Processing

DLP technology utilizes a digital projector screen to flash a single image of each layer across the entire platform at once. This process cures liquid resin into hardened plastic, building up the part layer by layer. The key advantage of DLP over other 3D printing methods is its speed and precision, as entire layers are cured simultaneously rather than tracing out each part of the layer individually.

Material Innovations for DLP Printing

Modern photopolymer resins have substantially increased DLP technology's potential for low volume manufacturing. These materials can be shaped to resemble injection-molded technical plastics in terms of their flexibility, heat resistance, and durability. Possibilities for creating functioning end-use parts are expanded when some resins combine ceramic or metal particles.

Achieving Injection-Molding Quality with DLP

DLP technology can achieve surface finishes and dimensional accuracies comparable to injection molding. The layer-by-layer curing process, combined with high-resolution projectors, results in parts with smooth surfaces and fine details. Post-processing techniques such as sanding, painting, or coating can further enhance the appearance and functionality of DLP-printed parts, making them indistinguishable from injection-molded counterparts in many cases.

Advantages of DLP for Low Volume Production

Cost-Effectiveness in Small Batch Manufacturing

One of the most significant advantages of DLP technology for low volume production is its cost-effectiveness. Without the need for expensive molds or tooling, manufacturers can produce small quantities of parts at a fraction of the cost of traditional methods. This makes it an ideal solution for startups, custom product manufacturers, and companies looking to test market demand before scaling up production.

Rapid Turnaround and Design Flexibility

DLP technology enables rapid turnaround times for low volume manufacturing and production. Parts can be produced within hours or days, rather than weeks or months required for traditional tooling. This speed allows for quick iterations and design changes, supporting agile product development processes. The design flexibility offered by DLP is unparalleled, as complex geometries and intricate details can be produced without the constraints of traditional manufacturing methods.

Scalability and Customization Potential

DLP technology offers scalability that aligns perfectly with the needs of low volume manufacturing. As demand grows, production can be easily scaled up by adding more printers or transitioning to larger DLP systems. Mass customization is now within reach for companies in all kinds of industries thanks to digital processes that make it feasible to personalize each element without increasing equipment expenses.

Conclusion

Low volume manufacturing and production with injection-molding quality using DLP technology represents a significant leap forward in manufacturing capabilities. Digital laser printing (DLP) gives companies of all sizes access to previously unavailable opportunities by fusing the accuracy and smoothness of injection molding with the adaptability and affordability of 3D printing. Material science is advancing at a quick pace, and DLP systems are maturing, thus this technology will play a crucial role in manufacturing in the future. By bridging the hole between model and mass generation, it will give unparalleled quality and productivity.

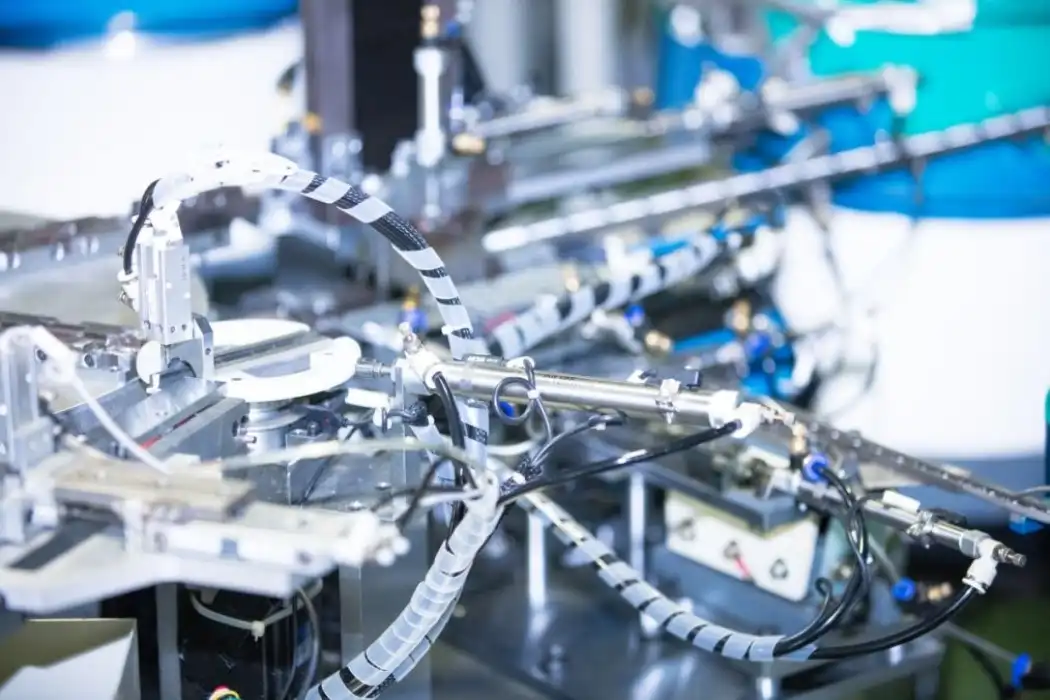

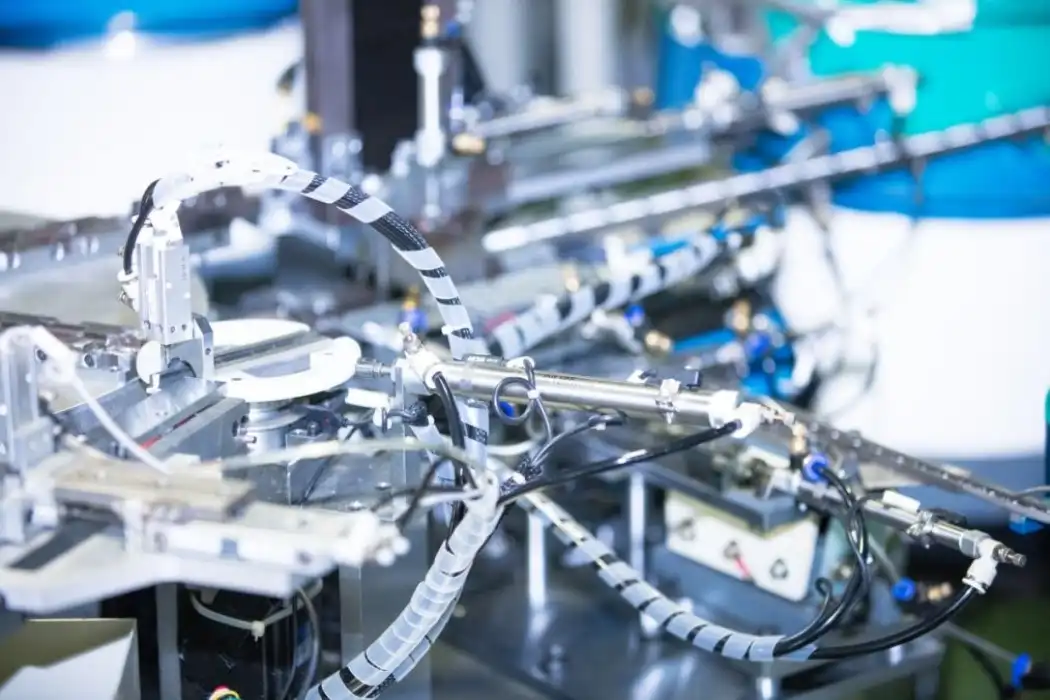

Low-Volume DLP Solutions with Perfect Details | BOEN

At BOEN Prototype, our advanced DLP systems, combined with our extensive knowledge of materials and integrated production processes, enable us to tackle even the most complex manufacturing challenges. In arrange to ensure that your components are up to standard in terms of exactness and clean, we give lightning-fast turnaround times without relinquishing quality. Whether you're in automotive, medical devices, aerospace, consumer electronics, or agriculture, BOEN has the expertise to bring your designs to life with injection-molding quality using cutting-edge DLP technology.

Experience the BOEN difference in low volume production. Send an e-mail to contact@boenrapid.com if you would like extra points of interest with respect to our DLP arrangements and how they might help you with your fabricating prerequisites.

References

Johnson, A. (2022). "Advancements in DLP Technology for Low Volume Manufacturing". Journal of Advanced Manufacturing Technologies, 15(3), 245-260.

Smith, R., & Brown, T. (2021). "Comparative Analysis of Injection Molding and DLP 3D Printing for Small Batch Production". International Journal of Industrial Engineering, 28(2), 112-128.

Lee, S. et al. (2023). "Material Innovations in Photopolymer Resins for DLP Technology". Advanced Materials Research, 42(1), 78-95.

Garcia, M., & Wilson, D. (2022). "Cost-Benefit Analysis of DLP Technology in Low Volume Production Scenarios". Manufacturing Economics Review, 33(4), 301-318.

Thompson, E. (2021). "The Impact of DLP Technology on Product Development Cycles". Journal of Product Innovation Management, 38(5), 412-429.

Chen, Y., & Davis, L. (2023). "Quality Comparison Between Injection Molded Parts and DLP Printed Components". Quality Engineering, 29(2), 156-172.