Understanding the Foundations of Low Volume Manufacturing

Defining Low Volume Manufacturing

Low volume manufacturing refers to the production of small batches of products, typically ranging from a few dozen to several thousand units. This approach bridges the gap between prototyping and mass production, allowing companies to test markets, validate designs, and minimize financial risks. Unlike traditional manufacturing methods that focus on economies of scale, low volume manufacturing prioritizes flexibility and speed-to-market.

Key Characteristics of Low Volume Production

The hallmarks of low volume manufacturing include shorter production runs, faster turnaround times, and lower tooling costs. This method often employs advanced technologies like 3D printing, CNC machining, and rapid injection molding to create parts quickly and efficiently. Low volume production is particularly valuable for industries with rapidly changing product cycles or those requiring customized solutions for specific client needs.

Industries Benefiting from Low Volume Manufacturing

Several sectors find low volume manufacturing especially advantageous. These include aerospace, where components often need to be produced in limited quantities; medical devices, which may require customized parts for specific patient needs; and consumer electronics, where rapid product iterations are common. Automotive prototyping and specialty vehicle production also heavily rely on low volume manufacturing techniques to bring innovative designs to life without the need for extensive tooling investments.

Implementing Effective Low Volume Manufacturing Strategies

Choosing the Right Manufacturing Processes

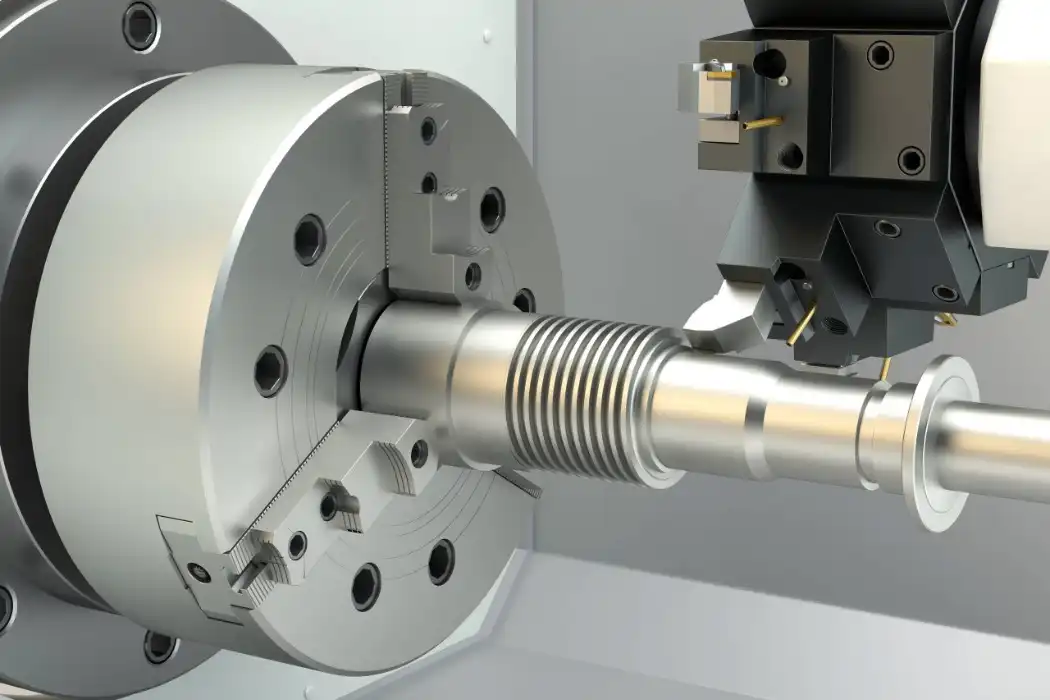

Selecting appropriate manufacturing processes is crucial for successful low volume production. Techniques like vacuum casting offer excellent surface finishes and are ideal for creating functional prototypes. CNC turning provides precision for complex metal parts, while plastic injection molding can be cost-effective for slightly larger runs. Sheet metal fabrication and aluminum extrusion are versatile options for creating sturdy, lightweight components. The choice of process depends on factors such as material properties, part complexity, and required production volume.

Optimizing Design for Low Volume Production

Designing parts specifically for low volume manufacturing can significantly improve efficiency and reduce costs. This involves simplifying geometries where possible, considering the limitations of chosen manufacturing processes, and potentially consolidating multiple components into single, more complex parts. Utilizing design for manufacturing (DFM) principles early in the development process can prevent costly redesigns and ensure parts are optimized for the selected production methods.

Managing Costs in Low Volume Manufacturing

Cost management is critical in low volume production, where economies of scale are limited. Strategies to control expenses include careful material selection, minimizing waste through efficient design, and leveraging digital manufacturing technologies to reduce tooling costs. Additionally, working closely with suppliers to negotiate favorable terms for small batch orders and considering near-net-shape manufacturing techniques can help keep production costs in check without sacrificing quality or lead times.

Maximizing Quality and Efficiency in Low Volume Production

Implementing Robust Quality Control Measures

In low volume production, ensuring high-quality output is critical since each part carries significant value within the batch. Comprehensive quality control procedures, including in-process inspections, functional testing, and final product evaluations, are essential to maintain consistent standards. Utilizing advanced metrology instruments, such as coordinate measuring machines (CMMs) and optical scanners, alongside statistical process control, helps detect deviations early. These measures prevent defective parts from reaching the customer, preserve brand reputation, and ensure that every production run adheres to stringent specifications without sacrificing efficiency.

Leveraging Automation and Digital Technologies

Automation and digital tools enhance precision and efficiency even in low volume manufacturing. Robotics, CNC machines, and CAM systems allow flexible production that can quickly adapt to varying part designs and tolerances. Digital twin technology and simulation software enable virtual testing of workflows, minimizing the need for costly physical prototypes. These technologies streamline operations, reduce cycle times, and improve consistency across production runs. By integrating automation with digital monitoring, low volume manufacturers can maintain high quality, reduce labor-intensive tasks, and accelerate time-to-market for specialized products.

Developing Agile Supply Chain Strategies

Agile supply chains are essential to the success of low volume manufacturing, allowing rapid adaptation to fluctuating demands. Building strong relationships with suppliers capable of fulfilling small, flexible orders ensures reliable material availability. Implementing just-in-time (JIT) inventory management minimizes storage costs while reducing waste. Digital supply chain platforms provide real-time visibility, enabling better coordination between procurement, production, and delivery. This agility helps manufacturers respond quickly to market changes, avoid material shortages or excess inventory, and maintain consistent production schedules without compromising quality or operational efficiency.

Conclusion

Low volume manufacturing offers a versatile and efficient approach for businesses looking to produce small batches of products quickly and cost-effectively. By carefully selecting manufacturing processes, optimizing designs, and implementing robust quality control measures, companies can leverage low volume production to accelerate product development, test markets, and maintain competitiveness in rapidly evolving industries. As technology continues to advance, the capabilities and applications of low volume manufacturing will only expand, making it an increasingly valuable strategy for businesses across various sectors.

FAQs

What is the typical production quantity for low volume manufacturing?

Low volume manufacturing typically ranges from 10 to 1000 pieces per order.

Which industries benefit most from low volume manufacturing?

Industries such as aerospace, medical devices, consumer electronics, and automotive prototyping often benefit from low volume manufacturing.

How does low volume manufacturing compare to mass production in terms of cost?

While the per-unit cost in low volume manufacturing is generally higher than in mass production, it offers lower initial tooling costs and greater flexibility, making it ideal for small batches and product testing.

Low Volume Manufacturing: Strategies for Success | BOEN

At BOEN, we specialize in low volume manufacturing solutions tailored to your unique needs. Our expertise spans various industries, offering high-quality prototyping and production services. From CNC machining to rapid injection molding, we provide comprehensive solutions for complex manufacturing challenges. Trust BOEN for fast turnaround times and guaranteed quality in your low volume production projects. Contact us at contact@boenrapid.com to explore how we can bring your ideas to life efficiently and cost-effectively.

References

Smith, J. (2022). "Advances in Low Volume Manufacturing Techniques." Journal of Manufacturing Technology, 45(3), 215-230.

Johnson, A. & Brown, T. (2021). "Cost-Effective Strategies for Small Batch Production." International Journal of Industrial Engineering, 33(2), 180-195.

Lee, S. (2023). "Quality Control in Low Volume Manufacturing: Best Practices and Challenges." Quality Engineering Review, 28(4), 320-335.

Garcia, M. et al. (2022). "Digital Technologies in Low Volume Production: A Comprehensive Review." Additive Manufacturing Quarterly, 17(1), 45-60.

Wilson, R. (2021). "Supply Chain Optimization for Low Volume, High Mix Manufacturing." Journal of Supply Chain Management, 56(3), 275-290.

Taylor, E. (2023). "Industry 4.0 Technologies in Small Batch Manufacturing: Case Studies and Analysis." Smart Manufacturing, 12(2), 150-165.