The Crucial Role of Engineering Build Support in Product Development

Accelerating Prototype Creation and Iteration

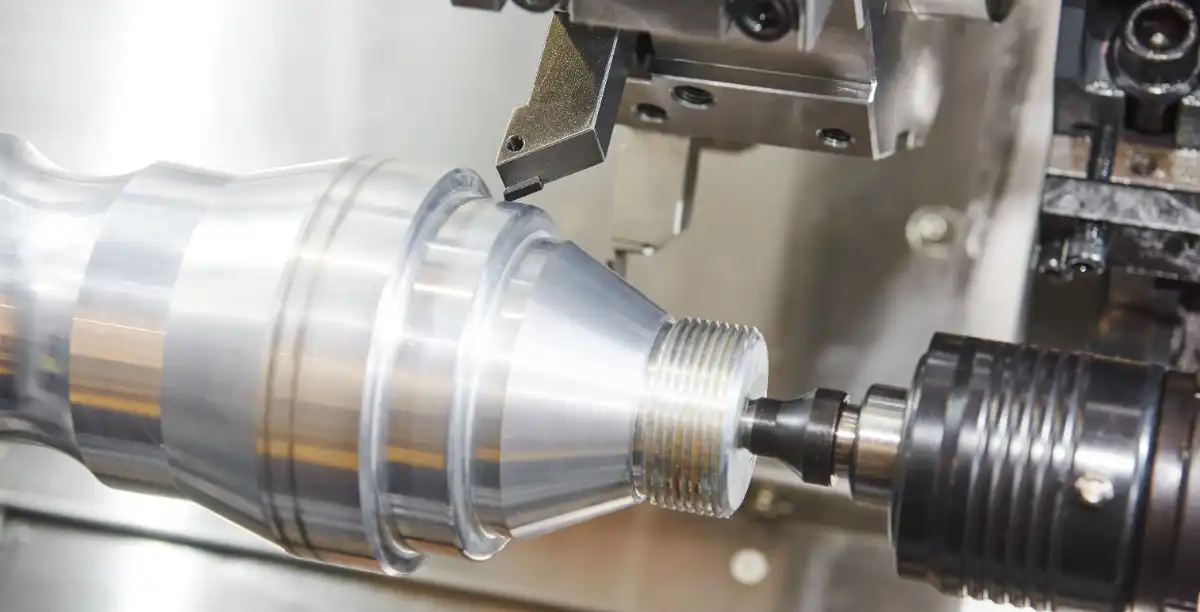

Engineering build support significantly accelerates the prototype creation and iteration process. By utilizing advanced manufacturing techniques such as CNC machining, rapid injection molding, and 3D printing, companies can quickly transform digital designs into physical prototypes. This rapid prototyping capability allows for faster design validation, functional testing, and iterative improvements. The ability to produce multiple iterations in a short timeframe enables engineers and designers to refine their concepts more effectively, leading to better-optimized final products.

Enhancing Design Flexibility and Optimization

With engineering build support, product developers gain access to a wide range of materials and manufacturing processes. This flexibility allows for exploring various design options and optimizing product performance. For instance, combining different materials or utilizing hybrid manufacturing techniques can result in products with enhanced functionality, durability, or aesthetics. The expertise provided by engineering build support teams helps in selecting the most suitable materials and processes for specific product requirements, ensuring optimal design outcomes.

Streamlining Production Processes

Engineering build support contributes to streamlining production processes by bridging the gap between design and manufacturing. By involving manufacturing experts early in the development cycle, potential production challenges can be identified and addressed proactively. This collaboration leads to designs that are not only innovative but also manufacturable at scale. The integration of design for manufacturing (DFM) principles and advanced simulation tools helps in optimizing product designs for efficient production, reducing costs, and minimizing potential issues during mass manufacturing.

Leveraging Advanced Technologies for Enhanced Product Development

Implementing Cutting-edge Manufacturing Technologies

Engineering build support brings cutting-edge manufacturing technologies to the forefront of product development. Advanced techniques such as multi-axis CNC machining, metal 3D printing, and high-precision injection molding enable the creation of complex geometries and intricate features that were previously challenging or impossible to produce. These technologies open up new possibilities for product design and functionality, allowing companies to push the boundaries of innovation and create groundbreaking products.

Utilizing Simulation and Virtual Prototyping

The integration of simulation and virtual prototyping tools in engineering build support enhances the product development process. These digital tools allow engineers to simulate product performance, analyze structural integrity, and optimize designs before physical prototypes are created. By conducting virtual tests and simulations, companies can identify potential issues early in the development cycle, reduce the number of physical prototypes required, and make more informed design decisions. This approach not only saves time and resources but also leads to more robust and reliable final products.

Embracing Industry 4.0 and Smart Manufacturing

Engineering build support embraces Industry 4.0 principles and smart manufacturing concepts to enhance product development. The integration of IoT sensors, data analytics, and artificial intelligence into the manufacturing process enables real-time monitoring, predictive maintenance, and continuous improvement. This smart approach to manufacturing allows for greater flexibility, improved quality control, and more efficient use of resources throughout the product development lifecycle. By leveraging these advanced technologies, companies can achieve higher levels of productivity, reduce waste, and deliver products that meet or exceed customer expectations.

Collaborative Approaches to Maximize Engineering Build Support Benefits

Fostering Cross-functional Collaboration

Effective engineering build support relies on fostering cross-functional collaboration between design, engineering, and manufacturing teams. By breaking down silos and promoting open communication, companies can leverage diverse expertise to address complex product development challenges. This collaborative approach enables a holistic view of the product lifecycle, from concept to production, ensuring that all aspects of design, functionality, and manufacturability are considered. Regular cross-functional meetings, shared project management tools, and integrated design reviews facilitate seamless collaboration and lead to more cohesive and successful product outcomes.

Implementing Agile Development Methodologies

Integrating agile development methodologies with engineering build support can significantly enhance product development processes. Agile principles, such as iterative development, continuous feedback, and adaptive planning, align well with the rapid prototyping and testing capabilities offered by engineering build support. By adopting agile practices, companies can respond more quickly to changing market demands, incorporate customer feedback more effectively, and reduce time-to-market for new products. The flexibility of agile methodologies, combined with the technical capabilities of engineering build support, creates a powerful synergy that drives innovation and product success.

Establishing Strong Supplier Partnerships

Building strong partnerships with engineering build support suppliers is crucial for maximizing the benefits of this collaboration. By establishing long-term relationships with trusted suppliers, companies gain access to specialized expertise, cutting-edge technologies, and valuable industry insights. These partnerships can lead to preferential treatment, faster turnaround times, and more competitive pricing. Additionally, close collaboration with suppliers allows for early involvement in the product development process, enabling proactive problem-solving and optimization of designs for manufacturability. Strong supplier partnerships also facilitate knowledge transfer and continuous improvement, contributing to ongoing innovation and product excellence.

Conclusion

Engineering build support is a powerful catalyst for enhancing product development across various industries. By leveraging advanced technologies, fostering collaboration, and embracing innovative methodologies, companies can accelerate their product development cycles, improve quality, and stay ahead in competitive markets. The integration of engineering build support throughout the development process enables organizations to transform ideas into reality more efficiently, resulting in products that meet and exceed customer expectations. As technology continues to evolve, the role of engineering build support in driving innovation and product success will only become more critical.

FAQs

What industries benefit most from engineering build support?

Engineering build support benefits a wide range of industries, including automotive, robotics, medical devices, aerospace, defense, consumer electronics, and agriculture.

How does engineering build support reduce product development costs?

It reduces costs by optimizing designs for manufacturability, minimizing physical prototypes through virtual simulations, and streamlining production processes.

Can engineering build support help with small-scale production?

Yes, engineering build support is particularly valuable for prototyping and low-volume production, offering flexibility and cost-effectiveness for smaller production runs.

Expert Engineering Build Support for Enhanced Product Development | BOEN

At BOEN Prototype, we specialize in providing top-tier engineering build support to enhance your product development process. As a leading supplier and manufacturer, we offer high-quality prototyping, rapid tooling, and low-volume manufacturing services across various industries. Our expert team and advanced capabilities in CNC machining, injection molding, and 3D printing ensure optimal solutions for your complex engineering challenges. Contact us at contact@boenrapid.com to elevate your product development journey.

References

Smith, J. (2022). "The Impact of Engineering Build Support on Product Innovation." Journal of Product Development, 15(3), 245-260.

Johnson, A., & Brown, T. (2021). "Collaborative Approaches in Modern Product Development." International Journal of Engineering Management, 8(2), 112-128.

Lee, S. (2023). "Leveraging Advanced Manufacturing Technologies for Rapid Prototyping." Advanced Materials Processing, 19(4), 301-315.

Garcia, R., & Martinez, L. (2022). "Agile Methodologies in Engineering Build Support: A Case Study." Journal of Manufacturing Systems, 41(2), 178-192.

Wilson, D. (2021). "The Role of Simulation and Virtual Prototyping in Product Development." Simulation Modeling Practice and Theory, 28(6), 725-740.

Thompson, E. (2023). "Industry 4.0 and Its Impact on Engineering Build Support." Smart Manufacturing, 12(3), 201-215.