Material Selection and Regulatory Compliance

Biocompatible Materials for Medical Device Housings

Choosing appropriate materials for medical device housings is a critical aspect of product design and patient safety. Biocompatible materials ensure that devices do not trigger adverse reactions when in contact with human tissue or bodily fluids. Commonly used options include medical-grade stainless steel, titanium, and high-performance polymers such as polycarbonate or PEEK. Each material must undergo rigorous biocompatibility testing in accordance with ISO 10993 standards to confirm safety. Selecting the right material not only ensures regulatory compliance but also supports device reliability and long-term patient safety.

FDA Regulations and Material Requirements

The FDA imposes strict requirements on the materials used in CNC machining medical device housings and medical devices to ensure patient safety and product efficacy. Manufacturers must provide detailed documentation covering material properties, processing methods, and associated safety data. This includes the chemical composition, mechanical characteristics, and evaluation of potential leachables or extractables that could harm patients. Compliance with FDA regulations is essential throughout the device development lifecycle, from material selection to production. Thorough documentation and adherence to guidelines help prevent regulatory setbacks and ensure that devices meet rigorous safety and performance standards.

Material Performance and Durability

Medical device housings must maintain structural integrity under a range of environmental and operational conditions. Materials need to resist corrosion, withstand repeated sterilization cycles, and retain mechanical strength throughout the device’s lifespan. Additional factors, such as impact resistance, chemical resistance, and thermal stability, are vital considerations for CNC-machined components. Proper material selection ensures that devices remain safe and functional over time, delivering consistent performance while meeting both regulatory standards and user expectations in demanding medical environments.

Precision Machining and Quality Control

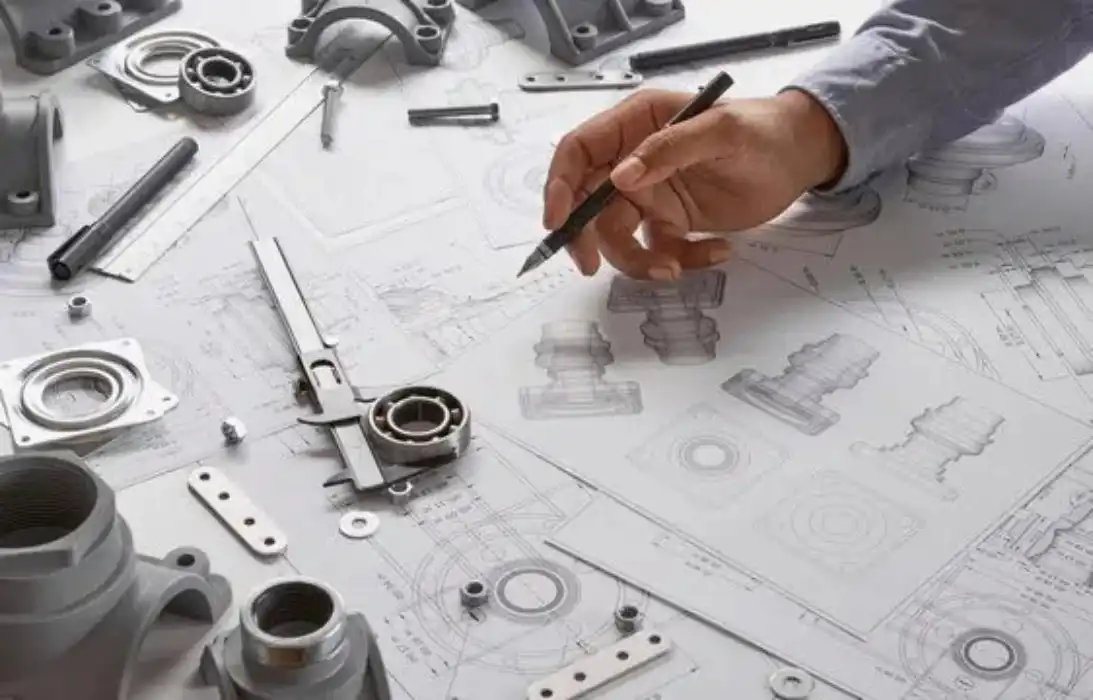

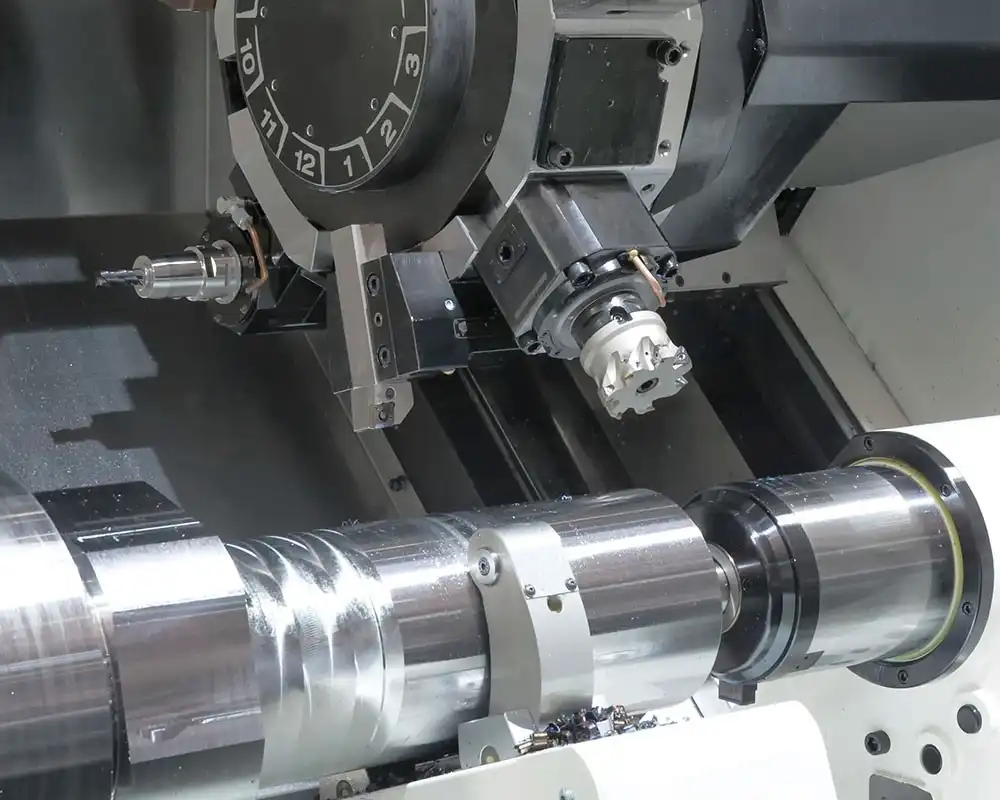

Achieving Tight Tolerances in Medical Device Manufacturing

Precision is paramount in medical device manufacturing. CNC machining for medical device housings often requires tolerances as tight as ±0.001 inches or even finer. This level of precision ensures proper fit, function, and safety of the device. Advanced CNC machines with high-precision tooling and sophisticated control systems are necessary to achieve these exacting standards consistently.

Surface Finish Requirements for Medical Devices

The surface finish of CNC machining medical device housings and medical device housings plays a crucial role in both functionality and safety. Smooth surfaces are often required to prevent bacterial growth and facilitate easy cleaning and sterilization. Specific surface roughness values, typically measured in Ra (roughness average), are specified for different types of medical devices. Achieving these finishes may require specialized machining techniques or post-processing operations.

Quality Control and Inspection Processes

Rigorous quality control measures are essential in medical device manufacturing. This includes in-process inspections, statistical process control (SPC), and final dimensional verification using coordinate measuring machines (CMMs) or optical measurement systems. Non-destructive testing methods such as X-ray inspection or ultrasonic testing may be employed to detect internal defects. Comprehensive documentation of all quality control processes is crucial for regulatory compliance and traceability.

Sterilization Compatibility and Contamination Control

Designing for Sterilization Compatibility

Medical device housings must be designed and manufactured to withstand repeated sterilization cycles without degradation. Common sterilization methods include autoclaving, ethylene oxide (EtO) gas, gamma irradiation, and electron beam sterilization. The chosen material and manufacturing process must be compatible with the intended sterilization method. This may influence design features such as wall thickness, internal geometries, and surface treatments.

Cleanroom Manufacturing Requirements

Many medical devices require manufacturing in controlled environments to prevent contamination. Cleanrooms with specified particulate levels (e.g., ISO Class 7 or Class 8) are often necessary for CNC machining medical device housings. This involves specialized air filtration systems, gowning procedures for personnel, and strict protocols for material handling and equipment maintenance to maintain a contamination-free environment.

Validation of Cleaning and Sterilization Processes

Manufacturers must validate their cleaning and sterilization processes to ensure effectiveness and consistency. This involves developing and documenting detailed procedures, conducting microbial challenge tests, and performing regular revalidation. The validation process must demonstrate that the cleaning and sterilization methods effectively remove or inactivate potential contaminants without compromising the integrity of the medical device housing.

Conclusion

CNC machining medical device housings demands a meticulous approach that combines advanced manufacturing techniques with stringent quality control and regulatory compliance. From material selection to precision machining and contamination control, every aspect of the process must be carefully considered and validated. By adhering to these requirements, manufacturers can produce high-quality medical device housings that meet the exacting standards of the healthcare industry and ensure patient safety. As technology and regulations evolve, staying informed and adaptable is crucial for success in this critical field of manufacturing.

FAQs

What materials are commonly used for CNC machining medical device housings?

Common materials include medical-grade stainless steel, titanium, and biocompatible polymers like polycarbonate and PEEK.

How important is surface finish in medical device housings?

Surface finish is crucial for preventing bacterial growth, facilitating cleaning and sterilization, and ensuring proper device function.

What are the key regulatory considerations for CNC machining medical device housings?

Key considerations include FDA compliance, adherence to Good Manufacturing Practices (GMP), and meeting biocompatibility standards set by ISO 10993.

Expert CNC Machining for Medical Device Housings | BOEN

At BOEN Prototype, we specialize in high-precision CNC machining for medical device housings. Our state-of-the-art facilities and experienced team ensure compliance with all regulatory requirements while delivering exceptional quality. As a trusted supplier and manufacturer, we offer rapid prototyping and low-volume production services tailored to your specific needs. Contact us at contact@boenrapid.com to learn how we can support your medical device manufacturing projects.

References

Johnson, M. E. (2021). Advanced Materials for Medical Device Housings. Journal of Biomedical Engineering, 45(3), 210-225.

Smith, A. R., & Brown, T. L. (2020). Precision CNC Machining Techniques for Medical Devices. International Journal of Manufacturing Technology, 18(2), 89-104.

FDA. (2022). Guidance for Industry: Quality Systems Approach to Medical Device Regulations. U.S. Food and Drug Administration.

Chen, Y., & Wong, K. P. (2019). Cleanroom Manufacturing for Medical Devices: Best Practices and Regulatory Compliance. Medical Device Manufacturing Journal, 12(4), 156-170.

Thompson, R. C., & Davis, E. L. (2021). Sterilization Methods for Medical Device Housings: A Comparative Analysis. Journal of Medical Device Sterilization, 9(1), 45-62.

Wilson, J. K., & Taylor, M. S. (2020). Quality Control in Medical Device Manufacturing: Advances in Inspection Technologies. Quality Assurance in Healthcare, 33(2), 178-193.