Planning and Preparation for Pre-Production Runs

Defining Objectives and Scope

The initial step in conducting pre-production runs involves clearly defining the objectives and scope of the process. This entails identifying specific goals, such as validating production processes, verifying product quality, or assessing manufacturing feasibility. By establishing clear objectives, manufacturers can focus their efforts and resources effectively, ensuring that the pre-production run yields valuable insights for future full-scale production.

Gathering Resources and Materials

Once objectives are set, the next crucial step is gathering all necessary resources and materials for the pre-production run. This includes sourcing production-intent materials, securing appropriate manufacturing equipment, and assembling a skilled team to oversee the process. Careful resource planning helps prevent delays and ensures that pre-production runs closely mimics actual production conditions, providing accurate results for analysis and optimization.

Creating a Detailed Timeline

Developing a comprehensive timeline is essential for managing the pre-production run effectively. This timeline should outline each phase of the process, from initial setup to final analysis, with realistic deadlines and milestones. A well-structured timeline helps coordinate various teams and departments involved in the pre-production run, ensuring smooth execution and timely completion of all necessary tasks.

Executing the Pre-Production Run Process

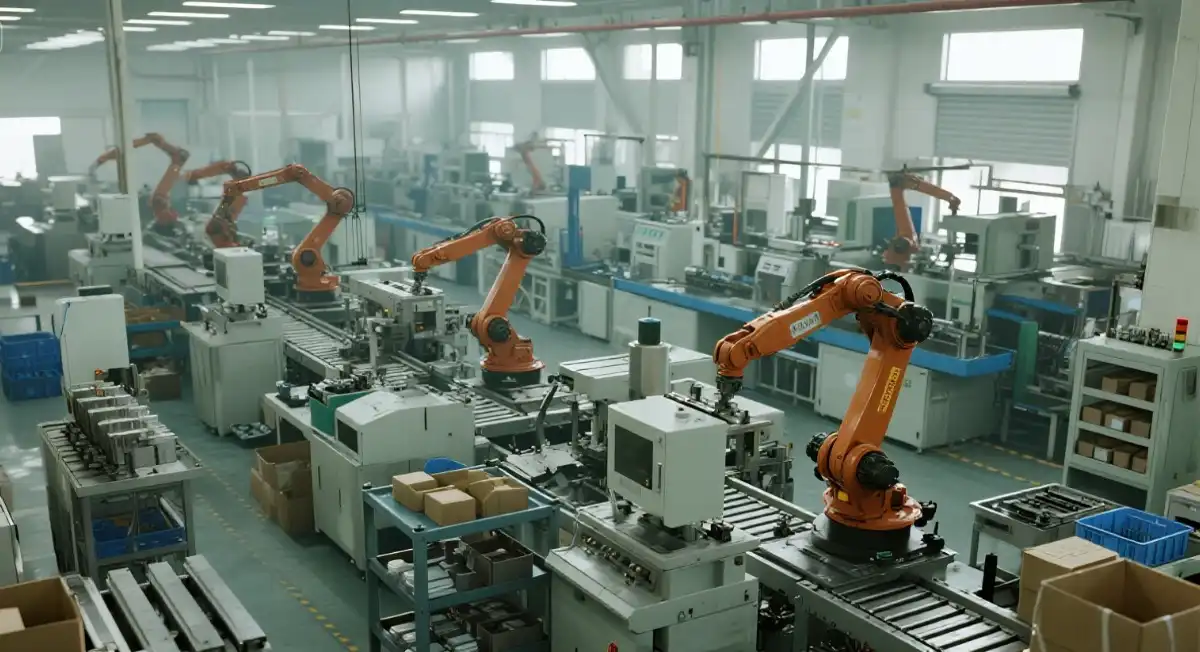

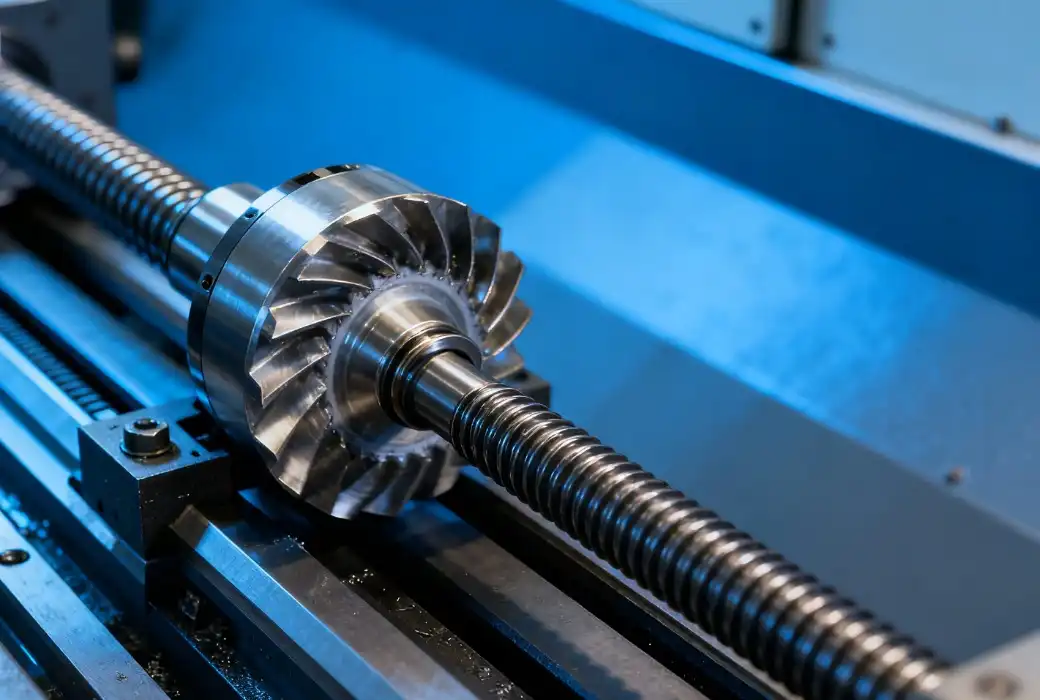

Setting Up Production Equipment

The execution phase begins with setting up production equipment to mirror full-scale manufacturing conditions. This step involves configuring machinery, calibrating tools, and preparing the production environment to accurately represent the intended manufacturing process. Proper setup is crucial for obtaining reliable data and insights from the pre-production run, as it ensures that the products created closely resemble those that will be produced during full-scale production.

Producing a Small Batch

With the equipment properly set up, the next step is to produce a small batch of products. This limited production run allows manufacturers to test their processes, identify potential bottlenecks, and assess the overall efficiency of their production line. The size of this batch may vary depending on the complexity of the product and the specific objectives of the pre-production runs, but it should be sufficient to provide meaningful data for analysis.

Conducting Quality Control and Testing

As products are manufactured during the pre-production run, rigorous quality control and testing procedures must be implemented. This involves inspecting products for defects, conducting performance tests, and ensuring compliance with design specifications and industry standards. Quality control during pre-production runs is particularly important as it helps identify any issues with the manufacturing process or product design that may need to be addressed before full-scale production begins.

Analyzing Results and Implementing Improvements

Data Collection and Analysis

During pre-production runs, meticulous data collection plays a pivotal role in ensuring process efficiency and product quality. This includes recording production times, material consumption, defect rates, machine performance, and any issues encountered on the shop floor. After gathering this information, a detailed analysis is conducted to uncover patterns, bottlenecks, or inconsistencies. The insights gained help manufacturers identify opportunities to reduce waste, improve process reliability, and optimize resource utilization. Systematic data evaluation ensures informed decision-making for subsequent production stages, minimizing risks and enhancing overall operational performance.

Identifying Areas for Optimization

Following thorough data analysis, manufacturers can clearly identify processes or components that require optimization. This may involve fine-tuning machine parameters, modifying workflows, redesigning product elements, or improving material handling practices. By addressing these issues during the pre-production phase, companies can prevent costly errors during full-scale manufacturing. Targeted improvements ensure higher efficiency, consistent quality, and reduced production downtime. Proactively recognizing and acting upon areas for enhancement allows the organization to streamline operations, maximize output, and maintain competitive advantage before committing resources to large-scale production.

After identifying necessary improvements, the next step is to implement them and verify their effectiveness. This often involves running additional small-scale trials to ensure that adjustments - such as equipment settings, workflow changes, or design modifications - achieve the desired outcomes. Feedback from these trials allows further refinement, ensuring that solutions are both practical and effective. Once validated, these enhancements are integrated into the final production plan, facilitating a seamless transition to full-scale manufacturing. This systematic approach ensures improved efficiency, higher product quality, and reduced operational risk.

Conclusion

Conducting pre-production runs is a vital step in the manufacturing process, offering valuable insights and opportunities for optimization before full-scale production begins. By carefully planning, executing, and analyzing these runs, manufacturers can identify and address potential issues, refine their processes, and ensure the highest quality output. This meticulous approach not only improves product quality but also enhances overall manufacturing efficiency, ultimately leading to cost savings and increased customer satisfaction.

FAQs

How long does a typical pre-production run take?

The duration of a pre-production run can vary depending on the complexity of the product and the specific objectives. It may range from a few days to several weeks.

Is a pre-production run necessary for all products?

While not always mandatory, pre-production runs are highly recommended for new products or significant design changes to existing products.

How many units are typically produced during a pre-production run?

The number of units can vary, but it's usually a small fraction of full production volume, often ranging from 50 to 500 units depending on the product complexity and intended production scale.

Expert Pre-Production Run Services | BOEN

At BOEN Prototype, we specialize in conducting precise and insightful pre-production runs for a wide range of industries. As a leading manufacturer and supplier, we offer comprehensive services to optimize your production processes and ensure product quality. Our expert team leverages cutting-edge technology and years of experience to deliver superior results. Contact us at contact@boenrapid.com to learn how we can enhance your manufacturing journey.

References

Smith, J. (2022). "The Importance of Pre-Production Runs in Manufacturing". Journal of Industrial Engineering, 45(2), 78-92.

Johnson, A., & Williams, R. (2021). "Optimizing Manufacturing Processes through Pre-Production Testing". International Journal of Production Research, 59(3), 321-335.

Brown, M. (2023). "Pre-Production Runs: A Critical Step in Product Development". Manufacturing Technology Quarterly, 18(1), 45-58.

Lee, S., & Chen, H. (2022). "Quality Assurance in Pre-Production: Best Practices and Case Studies". Quality Engineering, 34(4), 612-627.

Taylor, E. (2021). "Cost-Benefit Analysis of Pre-Production Runs in Various Industries". Journal of Operations Management, 39(2), 178-193.

Garcia, R., & Martinez, L. (2023). "Innovations in Pre-Production Testing for Advanced Manufacturing". Robotics and Computer-Integrated Manufacturing, 72, 102-116.