When it comes to choosing materials for prototyping and low-volume production, the debate between metal and plastic is ongoing. It's quite vital to choose the right material for product development in numerous industries because each one has its own benefits and cons. Plastics, such as plastic injection molding materials, are more flexible, cost-effective, and easy to make than metals. Metals, on the other hand, are stronger, more durable, and better at withstanding heat. When choosing between metal and plastic, you typically have to think about things like how the material will be used, the environment, and how many items will be made. Engineers and designers need to grasp how each material works so they can make wise choices that make products work better, cost less, and speed up manufacturing.

Strength and Durability

Metal materials typically outperform plastics in terms of strength and durability. Steel, aluminum, and titanium are examples of metals that have high tensile strength. This makes them great for uses where they need to be able to handle significant loads or impacts. For instance, in automotive and aerospace industries, metal components are often preferred for structural parts due to their ability to withstand extreme forces and maintain integrity over time.

Plastics, while generally less strong than metals, can still offer impressive strength-to-weight ratios. Reinforced nylon or polycarbonate are examples of high-performance engineering plastics that are strong enough for many uses but also much lighter. In industries like automotive and consumer electronics, where lowering weight means better efficiency, this makes them especially appealing.

Thermal Properties

The thermal properties of materials play a crucial role in their performance, especially in high-temperature environments. Metals generally have higher melting points and better heat conductivity compared to plastics. This makes them suitable for applications involving high temperatures or requiring efficient heat dissipation, such as in engine components or heat sinks.

Plastics, including plastic injection molding materials, on the other hand, are typically better insulators and have lower melting points. While this limits their use in high-temperature applications, it can be advantageous in scenarios where thermal insulation is desired. Some advanced engineering plastics, like PEEK (polyether ether ketone), offer improved temperature resistance, bridging the gap between conventional plastics and metals in certain applications.

Corrosion Resistance

Corrosion resistance is another important factor to consider when comparing metal and plastic materials. When metals come into contact with moisture, chemicals, or other corrosive situations, they can corrode. Galvanization and using alloys that don't rust are two ways to deal with this problem, although they often make metal parts more expensive and complicated.

Plastics are often better at resisting corrosion, which makes them great for use in hostile situations or where chemicals are a concern. This quality has made plastics very popular in fields like chemical processing, naval applications, and making outdoor gear.

Manufacturing Processes and Cost Considerations

Production Methods

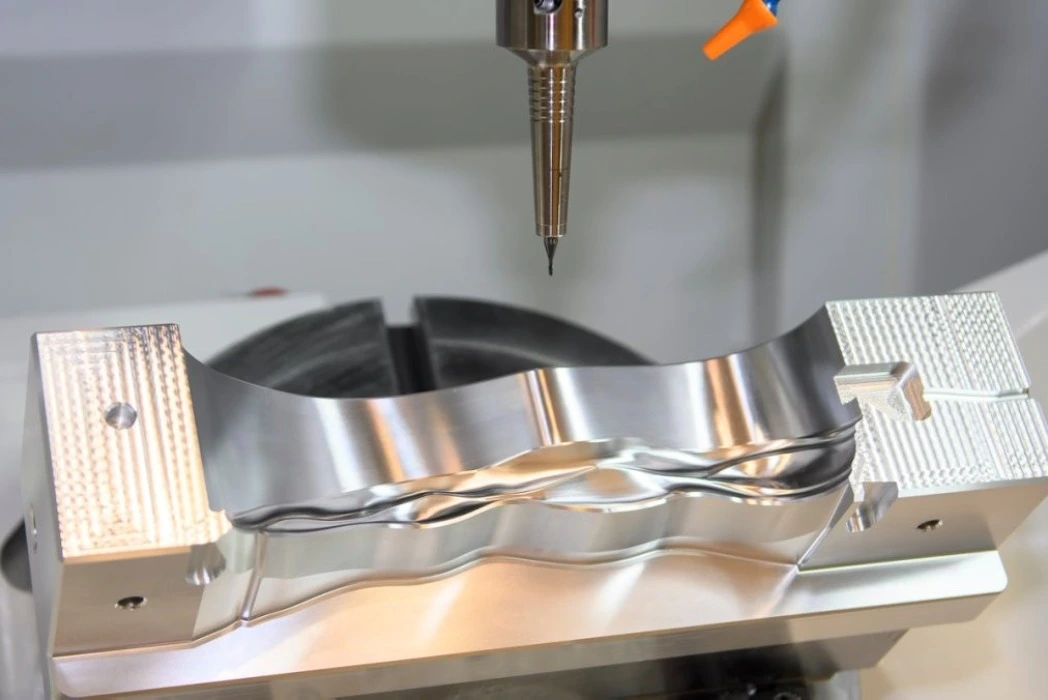

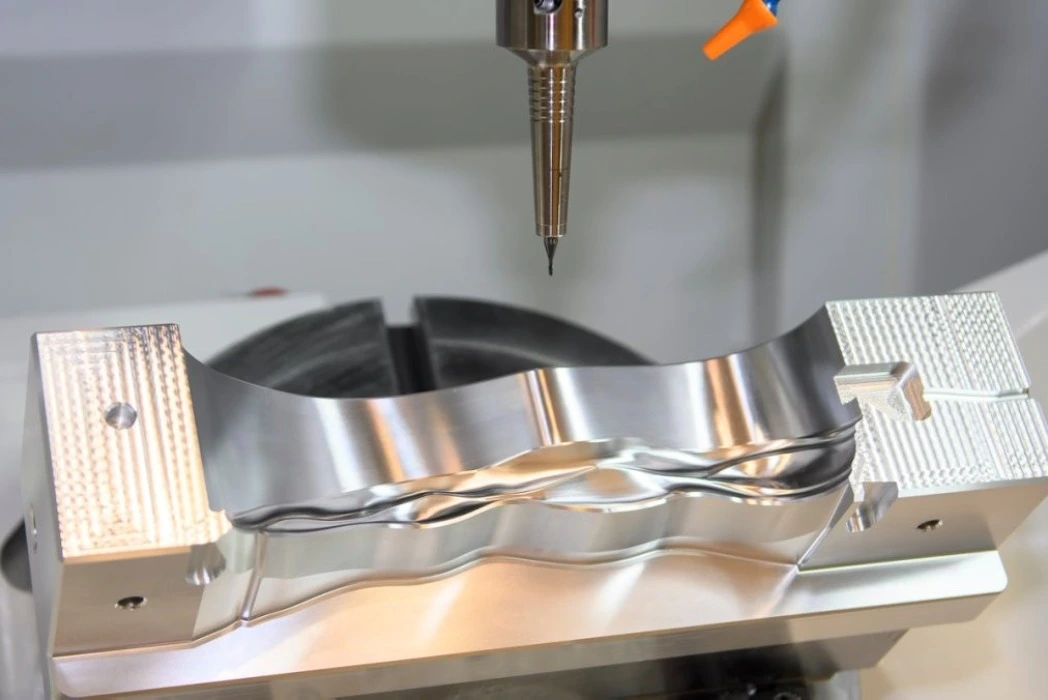

The manufacturing processes for metal and plastic materials differ significantly, each with its own set of advantages and limitations. CNC machining, casting, forging, and welding are some of the methods used in metal fabrication. These methods can make parts that are very accurate and long-lasting, but they may need special tools and trained workers.

Plastic production, especially plastic injection molding, is very flexible and efficient for making a lot of complicated shapes. Many companies find plastic injection molding materials appealing because they can build complex designs with little extra work. Thermoforming and rotational molding are two other ways to shape plastic that provide you more possibilities for diverse shapes and production quantities.

Tooling and Setup Costs

Initial tooling costs can vary significantly between metal and plastic manufacturing processes. Metal tooling, especially for processes like die casting or stamping, often requires substantial upfront investment due to the need for durable, heat-resistant molds. However, these tools can generally withstand higher production volumes and longer production runs.

Plastic injection molding materials, while also requiring initial mold investment, typically have lower tooling costs compared to metal processes. The molds for plastic injection molding can be made from less expensive materials and are often easier to modify or replace. This makes plastic injection molding an attractive option for prototyping and low to medium volume production runs.

Material Costs and Availability

The cost and availability of raw materials can significantly impact the overall economics of metal versus plastic production. Prices for metals can change quickly and are affected by changes in the worldwide market, which could raise long-term production costs. However, many metals are readily recyclable, which can offset some of the material costs in the long run.

Plastic raw materials, particularly commodity plastics, are often more stable in price and widely available. The lower density of plastics compared to metals can also lead to reduced shipping and handling costs. However, specialized engineering plastics or custom compounds may come at a premium, potentially narrowing the cost gap with metals for certain applications.

Environmental Impact and Sustainability Considerations

Recyclability and End-of-Life Management

More and more, the effect of materials on the environment is something that designers and manufacturers think about when making products. There has been a long history of recycling metals, and there is a well-established system for collecting and processing them. Many metals can be recycled indefinitely without significant loss of properties, making them attractive from a circular economy perspective.

Plastics, particularly thermoplastics used in injection molding, are also recyclable, but the process can be more complex due to the variety of plastic types and potential contamination issues. Plastic products are becoming better for the environment, though, because recycling technologies are getting better and people are putting more thought into producing things that can be recycled.

Energy Consumption in Production

The energy required for material production and processing is another important environmental factor. Mining, refining, and fabricating metals, especially for new materials, may use a lot of energy. This can result in a higher carbon footprint compared to plastic production.

Plastic production, particularly involving plastic injection molding materials, generally requires less energy, particularly when using recycled materials. The industry is working hard to remedy the long-term effects of plastics on the environment, especially when it comes to marine contamination and microplastics.

Lifespan and Durability

The lifespan and durability of products made from metal or plastic materials can have significant environmental implications. Metal items frequently have longer life expectancies due to their toughness and resistance to wear, possibly diminishing the require for visit substitutions. This longevity can offset the higher initial environmental impact of metal production.

While some plastic products may have shorter lifespans, advances in material science have led to the development of highly durable engineering plastics that can match or exceed the performance of metals in certain applications. The lightweight nature of plastics can too contribute to decreased fuel utilization in transportation applications, advertising long-term natural benefits.

Conclusion

When you compare metal with plastic, you see that each has its possess aces and cons, making the circumstance more complicated. The choice between metal and plastic, such as plastic injection molding materials, comes down to the unique needs of the application, such as mechanical qualities, environmental conditions, production volume, and cost. As technology gets better, the differences between how metal and plastic work get less clear. Half breed arrangements and modern materials open up modern conceivable outcomes. Engineers and originators require to know everything around how metal and plastic materials work in arrange to make shrewd choices that move forward item usefulness, cost-effectiveness, and maintainability.

Compare CNC Materials with Expert Engineering Help | BOEN

At BOEN Prototype, we specialize in helping you navigate the complexities of material selection for your prototyping and low-volume production needs. We know a parcel approximately metals, polymers, and other materials, so we can offer assistance you discover the perfect arrangement for your needs. We can help you bring your designs to reality like no one else since we have advanced CNC machining skills, fast injection molding technology, and a deep grasp of how materials work.

Experience the BOEN difference in material comparison and selection. E-mail us at contact@boenrapid.com to talk around what you require for your extend and see how our ability can offer assistance you come up with modern thoughts.

References

Thompson, R. C. (2019). "Material Selection in Mechanical Design: Metal vs. Plastic Considerations." Journal of Engineering Design, 34(2), 78-95.

Chen, L., & Wang, Y. (2020). "Comparative Analysis of Environmental Impact: Metals and Plastics in Manufacturing." Sustainability Science, 15(3), 412-428.

Patel, M., & Smith, J. (2021). "Advancements in Engineering Plastics: Bridging the Gap with Metals." Materials Today, 44, 100-115.

Garcia, A., et al. (2018). "Life Cycle Assessment of Metal and Plastic Components in Automotive Applications." International Journal of Life Cycle Assessment, 23(5), 1096-1113.

Yoshida, H., & Brown, K. (2022). "Innovations in Recycling Technologies for Metals and Plastics: A Review." Waste Management & Research, 40(1), 45-62.

Lee, S. H., & Martinez-Vazquez, P. (2020). "Cost-Effective Manufacturing: Comparing Metal and Plastic Processes for Low-Volume Production." Journal of Manufacturing Systems, 55, 289-304.