What is the Difference Between 3 and 5-Axis CNC

The main difference between 3-axis and 5-axis CNC machining lies in their movement capabilities and complexity of parts they can produce. 3-axis CNC machines move along three linear axes (X, Y, and Z), allowing for basic cutting operations in three dimensions. In contrast, 5-axis CNC machines add two rotational axes (A and B) to these linear movements, enabling the cutting tool to approach the workpiece from virtually any angle. This enhanced flexibility allows 5-axis machines to create more complex geometries, achieve better surface finishes, and often complete parts in a single setup, leading to improved efficiency and precision in manufacturing complex components.

Understanding the Basics of CNC Machining

What is CNC Machining?

CNC machining is a way to make things by using machines that are controlled by computers to take material away from a workpiece. This form of subtractive manufacturing uses exact instructions, usually made from 3D CAD models, to tell cutting equipment how to make complicated parts and pieces.

The Evolution of CNC Technology

Since its inception, CNC technology has undergone significant advancements. Old machines could only do simple tasks, while modern CNC systems can do very complicated tasks with amazing accuracy. As a result of this change, multi-axis machines have been created. The 3-axis and 5-axis CNC machining setups are two of the most common ones.

Key Components of CNC Systems

CNC systems consist of several crucial components, including the machine tool, control unit, and software interface. The machine tool holds the cutting tools and the workpiece, while the control unit reads the preset instructions and tells the tool how to move. Advanced software lets operators test and improve machining processes before they start making things.

Exploring 3-Axis CNC Machining

Principles of 3-Axis Machining

3-axis CNC machining operates using the Cartesian coordinate system, enabling movement along three linear axes: X (horizontal), Y (depth), and Z (vertical). In this configuration, the cutting tool moves in straight lines to shape the material, making it highly effective for machining parts with flat surfaces, slots, and holes. The simplicity of this setup makes it ideal for many basic manufacturing tasks. Because of its straightforward design and ease of use, 3-axis machining is often the starting point for many workshops and production facilities, especially for less complex projects.

Advantages and Limitations of 3-Axis CNC

3-axis CNC machines are popular with small to medium-sized businesses since they are cheap, easy to program, and don't need much maintenance. They work best for machining simple pieces that need straight cuts, drilled holes, and basic surface shapes. However, their limited axis movement can become a constraint when manufacturing complex or multi-angled parts. In such cases, operators often need to manually reposition the workpiece, which increases the number of setups, machining time, and the risk of misalignment or human error during the process compared to 5-axis CNC machining.

Applications of 3-Axis Machining

Despite technological advancements in multi-axis machining, 3-axis CNC systems continue to play a vital role in modern manufacturing. They are often used to make 2D profiles, signs, flat panels, and simple 3D designs. 3-axis machines are cheap and easy to use, which makes them useful for woodworking, engraving, mold production, and quick prototyping, among other things. Their straightforward operation and fast turnaround make them especially suitable for high-volume runs of simple parts or quick production of test pieces in early-stage product development or low-complexity custom fabrication projects.

Delving into 5-Axis CNC Machining

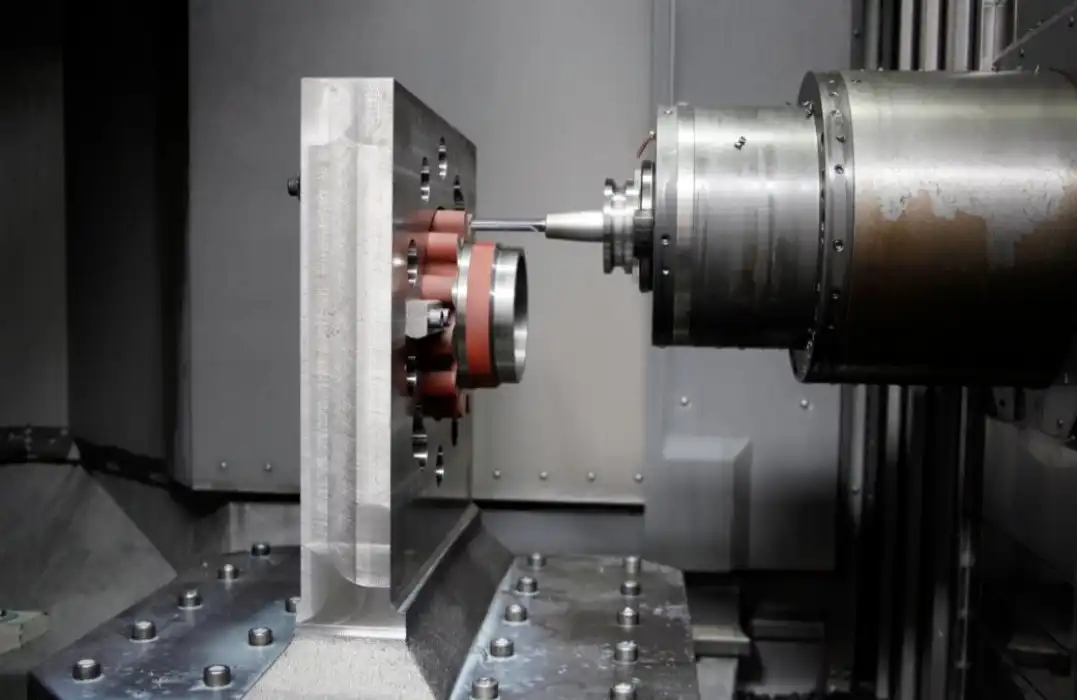

The Mechanics of 5-Axis Machining

5-axis CNC machining enhances the traditional 3-axis setup by adding two rotational axes, typically referred to as the A and B axes. These additional degrees of motion enable the cutting tool or the workpiece to rotate and tilt, allowing for access to nearly all part surfaces without repositioning. With this sophisticated movement, you may form complex shapes with fewer setups and more accuracy. For making high-precision parts with complex characteristics, especially ones that are hard or impossible to attain with traditional methods, 5-axis machining needs to be able to change quickly.

Advantages of 5-Axis CNC Machining

The advantages of 5-axis CNC machining extend far beyond traditional limitations. It allows for the production of highly complex parts - such as curved surfaces, deep cavities, and intricate undercuts - often in a single setup. This cuts down on the number of fixtures needed, lowers the risk of human mistake, and speeds up lead times. Being able to manufacture pieces from different angles also makes tools last longer and cuts better. Also, 5-axis machining gives surfaces a great polish, which cuts down on the need for a lot of post-processing and makes the whole manufacturing process run more smoothly.

Advanced Applications and Industries

5-axis CNC machining plays a vital role in industries that demand precision, complexity, and efficiency. Aerospace companies utilize it to make parts like turbine blades and structural brackets, where smooth edges and strict tolerances are very important. In the car industry, it makes it conceivable to make motor parts, custom molds, and lightweight parts. 5-axis machines are exceptionally imperative for making surgical disobedient, prosthesis, and inserts with incredible exactness for therapeutic gadget companies. These machines are moreover utilized in the mold-making and vitality businesses, which appears how valuable and vital they are in numerous cutting edge generation spaces.

Conclusion

The choice between 3-axis and 5-axis CNC machining depends on the complexity of the parts being produced and the specific requirements of the manufacturing process. 3-axis machines are easy to use and cheap for making simple parts, but 5-axis CNC machining is the best choice for making complex shapes since it is so flexible and efficient. As technology keeps getting better, the line between these two approaches may become less clear. Be that as it may, it is still critical to know what each one can do in arrange to make keen choices in fabricating and model ventures.

Unlock Complex Geometries with 5-Axis Expertise | BOEN

At BOEN, we pride ourselves on our advanced 5-axis CNC machining capabilities, which we've been refining since 2014. Our state-of-the-art DMG 5-axis CNC machines, imported from Germany, allow us to tackle the most challenging projects with precision and efficiency. These high-tech hardware let us work with littler cutters at tall speeds, which is incredible for businesses that require tight resistances and complicated shapes.

Experience the BOEN difference in 5-axis CNC machining. It would be ideal if you mail us at contact@boenrapid.com for more data approximately our administrations and how we may offer assistance with your generation needs.

References

Smith, J. (2022). Advanced CNC Machining Techniques: A Comprehensive Guide.

Johnson, L. et al. (2021). Comparative Analysis of 3-Axis vs 5-Axis CNC Machining in Aerospace Applications.

Brown, A. (2023). The Evolution of CNC Technology: From 3-Axis to Multi-Axis Systems.

Technical Institute of Manufacturing. (2022). Best Practices in 5-Axis CNC Machining for Complex Parts.

Zhang, Y. and Lee, K. (2021). Efficiency Improvements in Manufacturing through Advanced CNC Technologies.

Anderson, M. (2023). Industry 4.0 and the Role of Multi-Axis CNC Machining in Smart Factories.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.