The Evolution of Laser Cutting in Manufacturing

Historical Context of Laser Technology in Manufacturing

The journey of laser cutting in manufacturing began in the 1960s, shortly after the invention of the laser itself. Initially, the technology was limited to research laboratories and specialized applications. As laser systems became more robust and cost-effective, their adoption in industrial settings grew steadily. The 1980s saw a significant leap forward with the introduction of computer-controlled laser cutters, which dramatically improved precision and repeatability. This period marked the beginning of laser cutting's integration into mainstream manufacturing processes.

Advancements in Laser Cutting Techniques

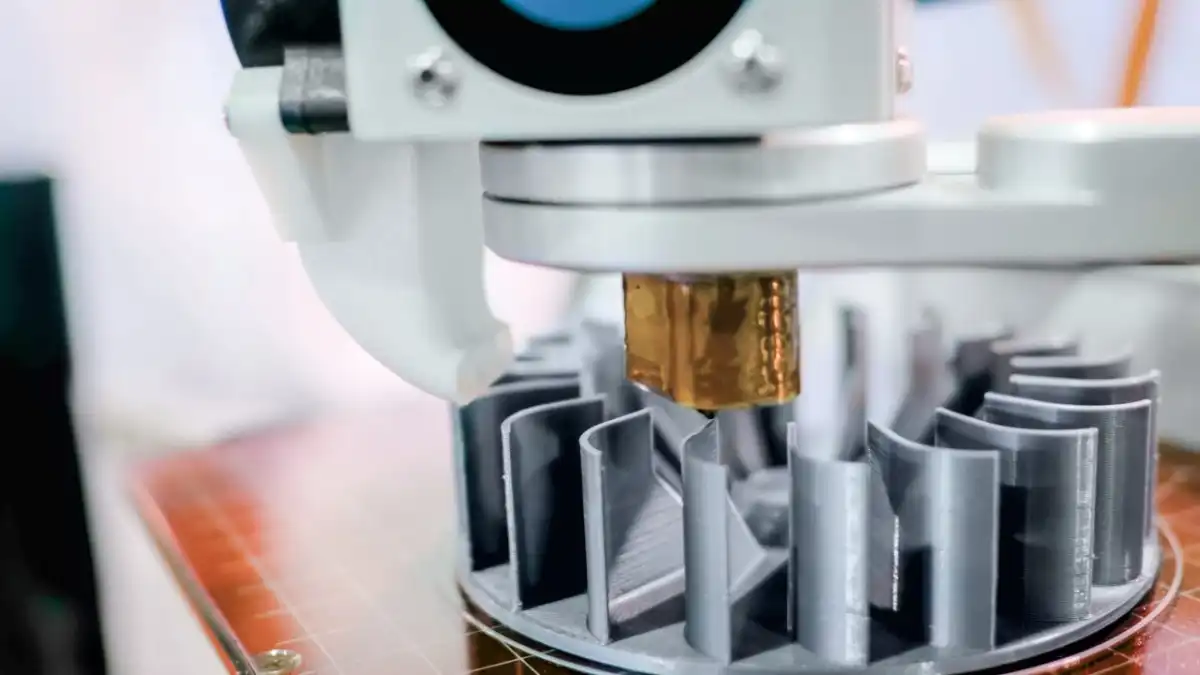

Over the years, laser cutting techniques have evolved substantially. Early systems were primarily CO2 lasers, suitable for cutting non-metallic materials. The development of fiber and solid-state lasers expanded capabilities to include efficient metal cutting. Modern laser cutting systems incorporate advanced optics, high-power lasers, and sophisticated control systems. These improvements have led to faster cutting speeds, the ability to work with thicker materials, and enhanced cut quality. Additionally, the emergence of 3D laser cutting has opened up new possibilities for complex part fabrication.

Impact on Manufacturing Processes

The integration of laser cutting into manufacturing processes has had a profound impact. It has significantly reduced setup times, minimized material waste, and improved overall production efficiency. Laser cutting's ability to produce intricate designs with high precision has enabled manufacturers to create products that were previously impractical or impossible to make. This technology has also facilitated rapid prototyping, allowing for faster design iterations and reduced time-to-market for new products. As a result, industries ranging from automotive to aerospace have seen substantial improvements in product quality and manufacturing flexibility.

Advantages of Laser Cutting in Precision Manufacturing

Unmatched Precision and Accuracy

One of the most significant advantages of laser cutting in precision manufacturing is its unparalleled accuracy. The focused laser beam can achieve cuts with tolerances as tight as ±0.1 mm, depending on the material and thickness. This level of precision is crucial in industries like medical device manufacturing, where even the slightest deviation can have serious consequences. The non-contact nature of laser cutting also means there's no tool wear, ensuring consistent accuracy over long production runs. This precision extends to complex geometries and intricate patterns that would be challenging or impossible with traditional cutting methods.

Versatility in Material Processing

Laser cutting technology demonstrates remarkable versatility in handling a wide range of materials. From metals like steel, aluminum, and titanium to non-metals such as plastics, wood, and ceramics, laser cutting can process diverse materials with ease. This versatility is particularly valuable in industries that require working with multiple materials or creating multi-component products. For instance, in the automotive industry, laser cutting is used for everything from cutting sheet metal body panels to trimming interior plastic components. The ability to switch between materials without changing tools or setups significantly enhances production flexibility and efficiency.

Enhanced Production Efficiency and Cost-Effectiveness

Laser cutting technology contributes significantly to enhanced production efficiency and cost-effectiveness in manufacturing. The high cutting speeds and automation capabilities of modern laser systems allow for rapid processing of parts, reducing production times dramatically. The precision of laser cutting also minimizes material waste, as parts can be nested closely together on raw material sheets. This efficiency extends to energy consumption, as laser cutting systems are often more energy-efficient than traditional cutting methods for certain applications. Moreover, the reduction in tooling costs and the ability to quickly switch between different part designs without retooling contribute to overall cost savings in manufacturing operations.

Applications and Future Trends in Laser Cutting Technology

Innovative Applications Across Industries

Laser cutting technology has found innovative applications across a diverse range of industries. In the aerospace sector, it's used to cut lightweight composite materials and precise holes in turbine blades. The medical industry utilizes laser cutting for manufacturing stents, surgical instruments, and implantable devices with extreme precision. In electronics manufacturing, lasers cut and score circuit boards and create microfluidic channels in lab-on-a-chip devices. The automotive industry employs laser cutting for everything from body panels to interior components. Even the fashion industry has embraced laser cutting for creating intricate patterns in fabrics and leather. These applications demonstrate the technology's versatility and its potential to revolutionize manufacturing processes across sectors.

Integration with Industry 4.0 and Smart Manufacturing

The integration of laser cutting technology with Industry 4.0 principles and smart manufacturing is a growing trend. Advanced laser cutting systems are being equipped with sensors and connected to IoT (Internet of Things) networks, enabling real-time monitoring and data collection. This integration allows for predictive maintenance, quality control, and process optimization. Machine learning algorithms can analyze the data to improve cutting parameters automatically, enhancing efficiency and reducing defects. The combination of laser cutting with robotics and automated material handling systems is creating fully automated production lines, capable of 24/7 operation with minimal human intervention. This trend towards smart, connected laser cutting systems is set to further boost manufacturing productivity and flexibility.

Emerging Trends and Future Prospects

The future of laser cutting technology looks promising, with several emerging trends on the horizon. One significant development is the increasing power and efficiency of laser sources, enabling faster cutting speeds and the ability to cut thicker materials. There's also a trend towards more compact and energy-efficient laser systems, making the technology accessible to smaller manufacturers. The development of ultra-short pulse lasers is opening up new possibilities for cutting extremely hard or brittle materials with minimal heat-affected zones. Another exciting prospect is the combination of laser cutting with additive manufacturing, creating hybrid systems capable of both adding and removing material in a single setup. As these technologies continue to evolve, we can expect to see even more innovative applications and improvements in manufacturing capabilities.

Conclusion

Laser cutting technology has undeniably revolutionized precision manufacturing, offering unparalleled accuracy, versatility, and efficiency. Its impact spans across industries, from automotive and aerospace to medical devices and electronics. As we look to the future, the integration of the product with smart manufacturing principles and emerging technologies promises even greater advancements. For companies seeking to stay at the forefront of manufacturing innovation, embracing laser cutting technology is not just an option but a necessity in today's competitive landscape.

FAQs

What materials can be processed using laser cutting technology?

Laser cutting can process a wide range of materials, including metals like steel and aluminum, as well as non-metals such as plastics, wood, and ceramics.

How does laser cutting compare to traditional cutting methods in terms of precision?

Laser cutting offers superior precision, with tolerances as tight as ±0.1 mm, often surpassing traditional methods, especially for complex geometries.

Is laser cutting suitable for small-scale or prototype production?

Yes, laser cutting is excellent for prototyping and small-scale production due to its flexibility and minimal setup requirements.

Experience Precision Manufacturing with Laser Cutting Technology | BOEN

At BOEN Prototype, we leverage advanced laser cutting technology to deliver precision manufacturing solutions for your prototyping and low-volume production needs. Our expertise in plastic and metal materials, combined with state-of-the-art laser cutting capabilities, ensures unparalleled accuracy and quality in every project. Experience the BOEN advantage in rapid prototyping and manufacturing. Contact us at contact@boenrapid.com to discuss your precision manufacturing requirements.

References

Johnson, A. (2022). "Advanced Laser Cutting Techniques in Modern Manufacturing". Journal of Precision Engineering, 45(3), 287-302.

Smith, B., & Brown, C. (2021). "Laser Technology in Aerospace Manufacturing: A Comprehensive Review". Aerospace Science and Technology, 112, 106598.

Lee, S., et al. (2023). "Integration of Laser Cutting with Industry 4.0: Challenges and Opportunities". Smart Manufacturing Systems, 8(2), 124-139.

Williams, R. (2020). "Precision Manufacturing: The Role of Laser Cutting in Medical Device Fabrication". Medical Device Technology, 31(4), 18-25.

Garcia, M., & Rodriguez, L. (2022). "Sustainable Manufacturing Practices: Laser Cutting's Contribution to Waste Reduction". Journal of Cleaner Production, 330, 129751.

Chen, H. (2021). "Emerging Trends in Laser Cutting Technology: A Future Perspective". International Journal of Advanced Manufacturing Technology, 115(5), 1523-1537.