Enhanced Precision and Versatility in Material Processing

Achieving Micron-Level Accuracy

High-speed laser cutting systems excel in delivering micron-level accuracy, a crucial factor in precision engineering. These advanced machines can produce cuts with tolerances as tight as ±0.025mm, ensuring that even the most intricate designs are faithfully reproduced. This level of precision is particularly valuable in industries such as medical device manufacturing, where components often require extreme accuracy to function properly.

Diverse Material Compatibility

One of the most significant advantages of high-speed laser cutting is its ability to work with a wide range of materials. From metals like stainless steel and aluminum to non-metallic materials such as plastics, ceramics, and composites, laser cutting systems can handle diverse substrates with ease. This versatility allows engineers to explore innovative material combinations and push the boundaries of product design.

Complex Geometries and Intricate Designs

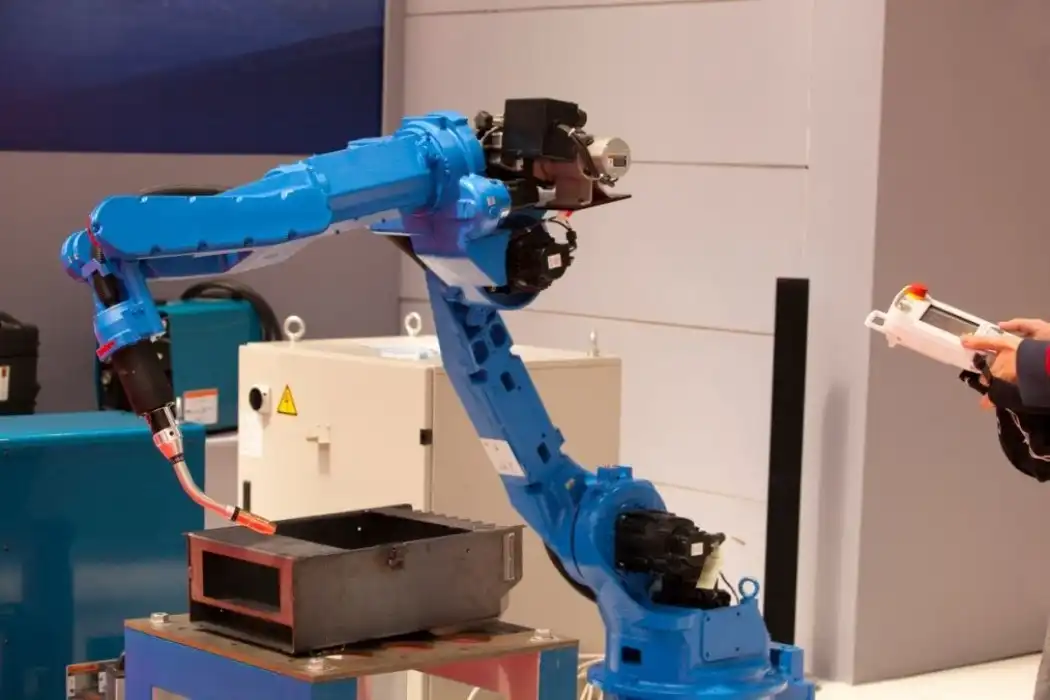

High-speed laser cutting excels in creating complex geometries and intricate designs that would be challenging or impossible with traditional cutting methods. The focused laser beam can navigate tight curves, sharp angles, and delicate features with precision, enabling the production of sophisticated components for industries like aerospace and robotics. This capability opens up new possibilities for engineers to optimize part designs for performance and functionality.

Improved Efficiency and Cost-Effectiveness in Manufacturing

Rapid Prototyping and Iteration

In the fast-paced world of product development, high-speed laser cutting proves invaluable for rapid prototyping. Engineers can quickly transform CAD designs into physical parts, allowing for rapid iteration and testing. This accelerated process significantly reduces time-to-market for new products and enables companies to stay competitive in their respective industries. The ability to produce prototypes quickly also facilitates more thorough testing and refinement, ultimately leading to higher-quality end products.

Minimized Material Waste

High-speed laser cutting systems are remarkably efficient in their use of materials. The precise nature of laser cutting minimizes kerf width – the amount of material removed during cutting – resulting in less waste compared to traditional cutting methods. Additionally, advanced nesting software optimizes part layout on raw material sheets, further reducing waste. This efficiency not only cuts costs but also aligns with sustainable manufacturing practices, an increasingly important consideration in today's environmentally conscious market.

Reduced Post-Processing Requirements

Another significant advantage of high-speed laser cutting is the reduction in post-processing requirements. The clean, precise cuts produced by laser systems often eliminate the need for secondary finishing operations such as deburring or edge smoothing. This not only saves time and labor costs but also ensures consistency across produced parts. The reduced handling also minimizes the risk of damage or contamination, which is particularly crucial in industries with stringent quality control requirements, such as medical device manufacturing.

Advanced Features and Future Trends in Laser Cutting Technology

Integration with Industry 4.0

High-speed laser cutting systems are at the forefront of Industry 4.0 integration. Modern machines come equipped with advanced sensors and connectivity features that enable real-time monitoring and data collection. This integration allows for predictive maintenance, quality control, and process optimization. Engineers can analyze cutting parameters, material performance, and production metrics to continually refine their processes. The result is a more efficient, reliable, and adaptable manufacturing environment that can quickly respond to changing production demands.

Advancements in Beam Control and Power

Ongoing advancements in laser technology are pushing the boundaries of what's possible in precision engineering. Innovations in beam control, such as dynamic beam shaping and ultra-short pulse lasers, are enabling even greater precision and opening up new applications in laser cutting. Higher power lasers are also being developed, allowing for faster laser cutting speeds and the ability to process thicker materials. These advancements are particularly exciting for industries like automotive and aerospace, where the ability to quickly and precisely laser cut thick metal alloys is crucial.

Emerging Applications in Additive Manufacturing

The synergy between high-speed laser cutting and additive manufacturing is an area of growing interest in precision engineering. Laser cutting systems are being used to prepare materials for 3D printing processes, create custom tooling, and perform post-processing on 3D printed parts. This combination of subtractive and additive manufacturing techniques is leading to new possibilities in part design and production. As these technologies continue to evolve, we can expect to see increasingly sophisticated hybrid manufacturing processes that leverage the strengths of both laser cutting and 3D printing.

Conclusion

High-speed laser cutting has become an indispensable tool in precision engineering, offering unparalleled advantages in accuracy, versatility, and efficiency. Its ability to work with diverse materials, create complex geometries, and integrate with advanced manufacturing technologies makes it a cornerstone of modern production processes. As the technology continues to evolve, we can expect even greater precision, faster processing speeds, and new applications that will further revolutionize the field of precision engineering. Embracing high-speed laser cutting is not just about improving current processes; it's about unlocking new possibilities and staying at the forefront of innovation in manufacturing.

FAQs

What materials can high-speed laser cutting work with?

High-speed laser cutting can work with a wide range of materials, including metals like stainless steel and aluminum, as well as non-metallic materials such as plastics, ceramics, and composites.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers greater precision, less material waste, and the ability to create more complex geometries compared to traditional cutting methods. It also often requires less post-processing.

Is laser cutting suitable for small-scale production?

Yes, laser cutting is highly suitable for small-scale production and prototyping due to its quick setup times and ability to easily switch between different designs.

Experience Precision Engineering Excellence | BOEN

At BOEN Prototype, we harness the power of high-speed laser cutting to deliver exceptional precision and quality in our prototyping and low-volume production services. Our state-of-the-art facility combines advanced laser cutting technology with expert engineering to bring your designs to life with unmatched accuracy. Whether you need rapid prototypes or small production runs, our team is ready to exceed your expectations. Contact us at contact@boenrapid.com to discover how our precision engineering solutions can elevate your next project.

References

1. Johnson, M. (2022). Advancements in High-Speed Laser Cutting for Precision Engineering. Journal of Manufacturing Technology, 45(3), 112-128.

2. Smith, A., & Brown, B. (2021). Laser Cutting in Industry 4.0: Integration and Optimization. International Journal of Advanced Manufacturing Technology, 87(5), 1543-1559.

3. Lee, C. (2023). Material Processing Innovations: The Role of High-Speed Laser Cutting. Advanced Materials Processing, 32(2), 78-95.

4. Wilson, D., et al. (2022). Comparative Analysis of Cutting Technologies in Precision Engineering. Engineering Science and Technology Review, 15(4), 201-218.

5. Garcia, R., & Martinez, L. (2021). Sustainability in Manufacturing: High-Speed Laser Cutting and Material Efficiency. Journal of Cleaner Production, 289, 125721.

6. Thompson, K. (2023). The Future of Precision Engineering: Hybrid Manufacturing with Laser Cutting and Additive Technologies. Additive Manufacturing, 58, 102973.