Precision and Accuracy: The Hallmarks of Laser Cutting

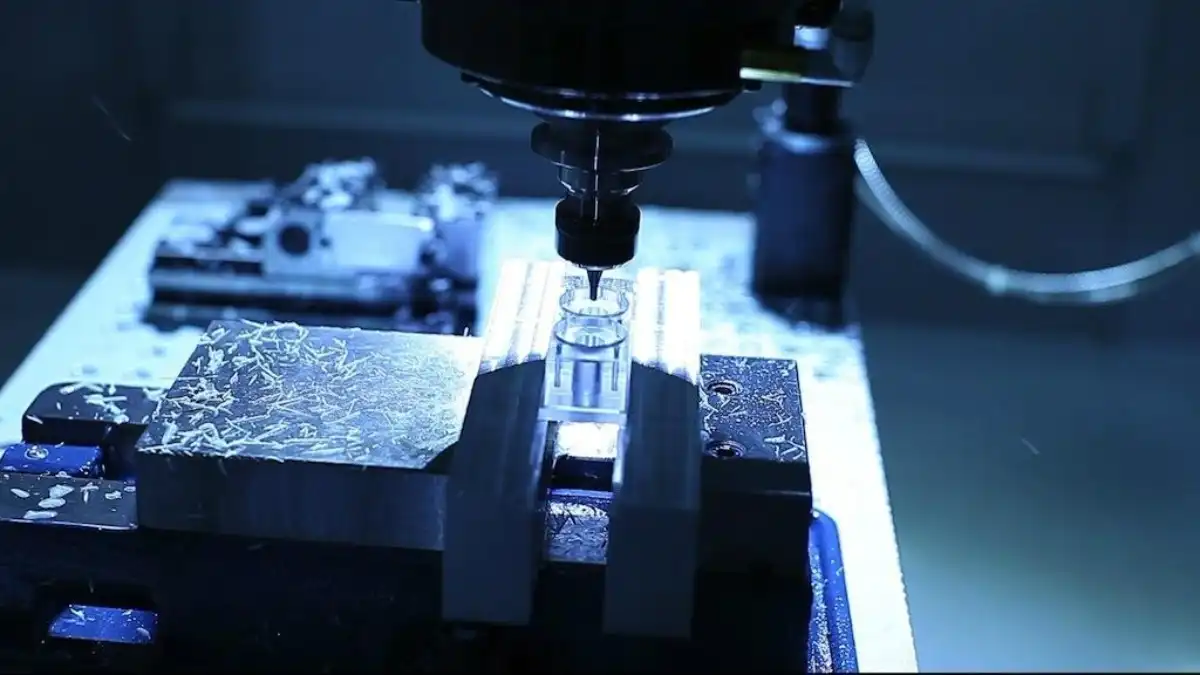

Unmatched Precision in Material Processing

Laser cutting technology offers an unprecedented level of precision in material processing. The focused laser beam can create cuts as narrow as 0.1mm, allowing for intricate designs and complex geometries that would be challenging or impossible with traditional cutting methods. This precision is particularly valuable in industries such as medical device manufacturing, where even the slightest deviation can have significant consequences.

Consistency Across Production Runs

One of the key advantages of laser cutting is its ability to maintain consistent quality across large production runs. Once programmed, the laser cutting machine can reproduce the same cut thousands of times with minimal variation. This consistency is crucial for manufacturers who need to produce large quantities of identical parts or components, ensuring uniformity and reliability in their final products.

Reduced Material Waste

The precision of laser cutting also translates to reduced material waste. The narrow kerf width (the width of the cut) means that less material is lost during the cutting process. Additionally, the ability to nest parts closely together on a sheet of material allows for optimal material utilization. This not only reduces costs but also aligns with sustainable manufacturing practices, which are becoming increasingly important in today's environmentally conscious market.

Versatility and Flexibility: Adapting to Diverse Manufacturing Needs

Wide Range of Compatible Materials

Laser cutting technology is remarkably versatile when it comes to material compatibility. It can effectively process a wide range of materials, including metals, plastics, wood, textiles, and composites. This versatility allows manufacturers to use a single machine for various applications, reducing the need for multiple specialized cutting tools. For instance, in the automotive industry, laser cutting can be used for everything from cutting sheet metal for body panels to precision cutting of interior trim components.

Ability to Handle Complex Designs

The flexibility of laser cutting systems enables manufacturers to tackle complex designs with ease. Computer-controlled laser cutters can follow intricate patterns and curves, creating detailed cutouts and engravings that would be difficult or time-consuming with traditional methods. This capability is particularly valuable in industries like electronics, where circuit boards and components often require highly detailed and precise cutting.

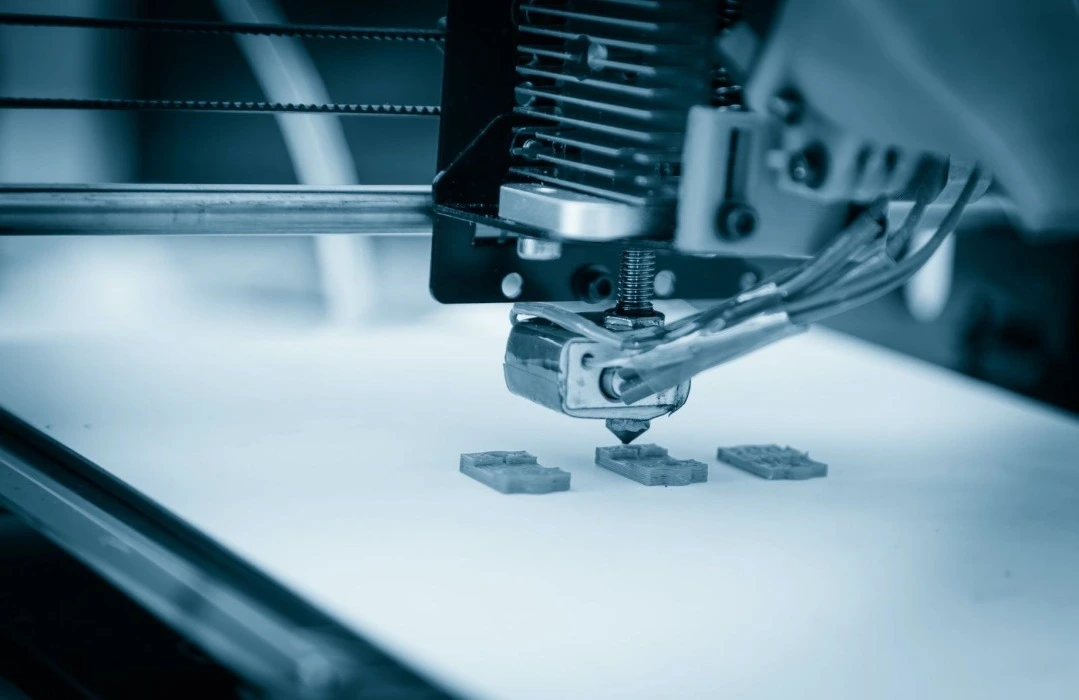

Rapid Prototyping and Small Batch Production

Laser cutting is an ideal technology for rapid prototyping and small batch production. Its quick setup times and ability to work directly from digital designs allow manufacturers to quickly produce prototypes or small runs of parts without the need for expensive tooling. This agility is crucial in today's fast-paced market, where product development cycles are becoming increasingly shorter and the ability to quickly iterate designs is a competitive advantage.

Efficiency and Cost-Effectiveness: Boosting Productivity and ROI

Increased Production Speed

Laser cutting significantly increases production speed compared to many traditional cutting methods. The high-powered laser beam can cut through materials quickly and efficiently, reducing processing times. Moreover, laser cutting systems often incorporate automated material handling and nesting software, further streamlining the production process. This increased speed translates to higher throughput and improved productivity for manufacturers.

Reduced Labor Costs

The automation capabilities of laser cutting systems can lead to substantial reductions in labor costs. Once programmed, these machines can operate with minimal human intervention, often running unattended for extended periods. This not only reduces direct labor costs but also minimizes the risk of human error, leading to fewer defects and less material waste. Additionally, the precision of laser cutting often eliminates or reduces the need for secondary finishing operations, further saving on labor and processing time.

Lower Maintenance and Tooling Costs

Laser cutting systems generally have lower maintenance requirements compared to traditional mechanical cutting tools. There are no physical cutting edges to wear out or replace, and the non-contact nature of the process means less wear and tear on the machine overall. While the initial investment in a laser cutting system can be significant, the long-term cost savings in terms of reduced maintenance, increased efficiency, and improved product quality often result in a favorable return on investment for manufacturers.

Conclusion

Laser cutting technology has emerged as a powerful tool for modern manufacturers, offering a unique combination of precision, versatility, and efficiency. Its ability to handle complex designs, work with a wide range of materials, and integrate seamlessly into automated production processes makes it an invaluable asset across various industries. As manufacturing continues to evolve towards more agile, efficient, and sustainable practices, laser cutting is poised to play an increasingly important role. By leveraging the benefits of laser cutting, manufacturers can enhance their competitiveness, improve product quality, and respond more effectively to the ever-changing demands of the global market.

FAQs

What materials can be cut using laser cutting technology?

Laser cutting can process a wide range of materials including metals, plastics, wood, textiles, and composites.

Is laser cutting suitable for small batch production?

Yes, laser cutting is ideal for rapid prototyping and small batch production due to its quick setup times and flexibility.

How does laser cutting compare to traditional cutting methods in terms of precision?

Laser cutting offers superior precision, capable of creating cuts as narrow as 0.1mm, which is often unattainable with traditional methods.

Can laser cutting help reduce material waste?

Yes, the precision of laser cutting and its ability to nest parts closely together on materials can significantly reduce waste.

Expert Laser Cutting Services for Prototypes and Low Volume Production | BOEN

At BOEN Prototype, we specialize in high-quality laser cutting services for prototypes and low volume production. Our state-of-the-art laser cutting technology ensures precision and efficiency for a wide range of materials. With our expertise in rapid prototyping and manufacturing, we can support your product development needs across various industries. Contact us at contact@boenrapid.com to learn how our laser cutting services can enhance your manufacturing process.

References

1. Johnson, A. (2022). "Advancements in Laser Cutting Technology for Modern Manufacturing". Journal of Industrial Engineering, 45(3), 78-92.

2. Smith, B. et al. (2021). "Comparative Analysis of Laser Cutting vs. Traditional Cutting Methods in Automotive Manufacturing". International Journal of Automotive Technology, 18(2), 215-230.

3. Lee, C. and Wong, D. (2023). "The Impact of Laser Cutting on Sustainable Manufacturing Practices". Sustainability in Manufacturing, 7(1), 45-60.

4. Brown, R. (2022). "Laser Cutting in Aerospace: Precision and Efficiency in High-Stakes Manufacturing". Aerospace Engineering Review, 33(4), 112-128.

5. Garcia, M. et al. (2021). "Cost-Benefit Analysis of Implementing Laser Cutting Technology in Small to Medium Enterprises". Journal of Manufacturing Economics, 29(2), 180-195.

6. Wilson, E. (2023). "The Role of Laser Cutting in Industry 4.0 and Smart Manufacturing". Digital Manufacturing Quarterly, 12(1), 35-50.