The Role of CNC in Modern Manufacturing: An Overview

Computer Numerical Control (CNC) has revolutionized modern manufacturing, transforming the way products are designed, prototyped, and produced. This advanced technology allows for precise control of machine tools through computer programming, enabling the creation of complex parts with unparalleled accuracy and efficiency. CNC manufacturing has become an integral part of various industries, from aerospace and automotive to medical devices and consumer electronics. By automating the production process, CNC machines have significantly improved productivity, reduced human error, and enhanced the overall quality of manufactured goods. This overview explores the critical role of CNC in shaping today's manufacturing landscape, highlighting its benefits, applications, and impact on industry practices.

The Evolution and Fundamentals of CNC Manufacturing

Historical Development of CNC Technology

The roots of CNC technology can be traced back to the 1940s and 1950s when the concept of numerical control was first introduced. Initially, machines were controlled by punched tape or cards, which contained coded instructions for tool movements. As computer technology advanced, these systems evolved into the sophisticated CNC machines we know today. This progression has led to more precise, faster, and more versatile manufacturing capabilities, revolutionizing industries worldwide.

Core Components of CNC Systems

Modern CNC manufacturing systems consist of several key components working in harmony. The heart of a CNC machine is its computer, which interprets programmed instructions and controls the machine's movements. Servo motors and drive systems translate these commands into physical motion, while cutting tools and workholding devices manipulate the material. Advanced sensors and feedback mechanisms ensure accuracy throughout the process, allowing for real-time adjustments and quality control.

The CNC Programming Process

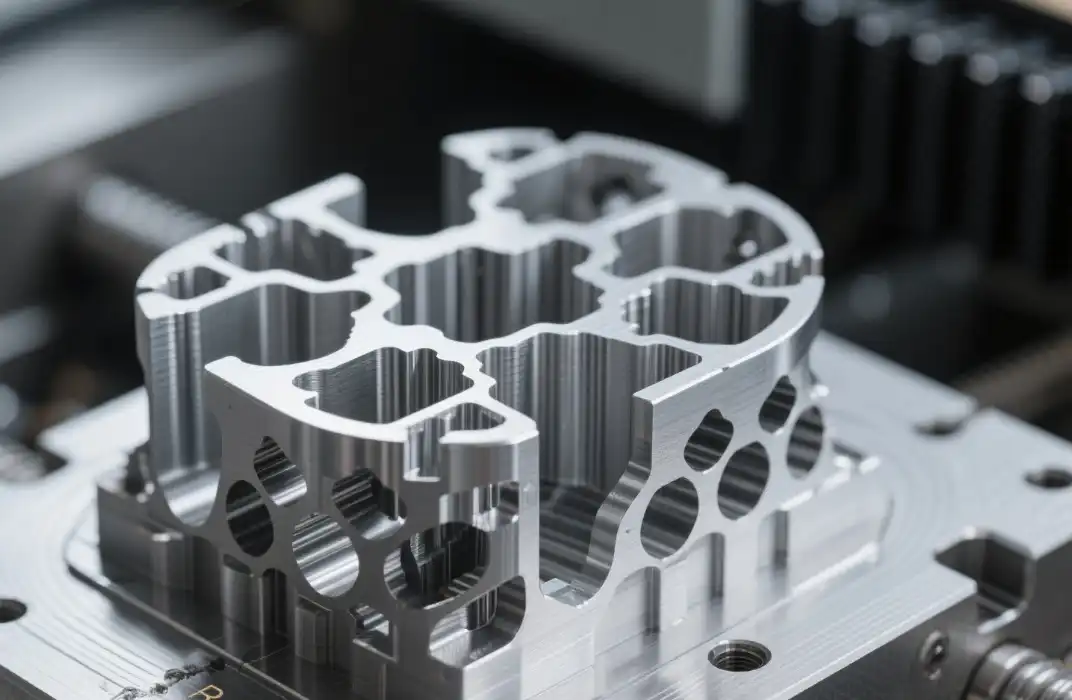

CNC programming is a crucial aspect of the manufacturing process. It involves creating a set of instructions that guide the machine's operations. Programmers use Computer-Aided Design (CAD) software to create 3D models of parts, which are then translated into machine-readable code through Computer-Aided Manufacturing (CAM) software. This code, often in G-code format, provides step-by-step directions for the CNC machine, controlling everything from tool paths to cutting speeds and depths.

Applications and Advantages of CNC in Modern Industries

Diverse Industrial Applications

CNC technology has found applications across a wide range of industries. In aerospace, it's used to create precision components for aircraft and spacecraft. The automotive sector relies on CNC for producing engine parts, body panels, and prototypes. Medical device manufacturers use CNC machines to craft intricate implants and surgical instruments. Even the electronics industry benefits from CNC technology in the production of circuit boards and device casings. This versatility has made CNC an indispensable tool in modern manufacturing.

Precision and Repeatability

One of the most significant advantages of CNC manufacturing is its ability to produce highly accurate parts consistently. CNC machines can achieve tolerances as tight as a few microns, ensuring that each produced part meets exact specifications. This level of precision is crucial in industries where even minor deviations can have serious consequences, such as in aerospace or medical device manufacturing. Moreover, the repeatability of CNC processes means that whether producing one part or thousands, each item will be virtually identical, maintaining consistent quality across production runs.

Efficiency and Cost-Effectiveness

CNC manufacturing offers substantial improvements in efficiency compared to traditional methods. Once programmed, CNC machines can operate continuously with minimal human intervention, significantly reducing labor costs and increasing production output. The ability to quickly switch between different parts or designs by simply changing the program also enhances flexibility in production schedules. Additionally, CNC machining minimizes material waste through optimized cutting paths and the ability to nest multiple parts within a single piece of raw material, contributing to cost savings and environmental sustainability.

Challenges and Future Trends in CNC Manufacturing

Overcoming Skill Gaps

As CNC technology continues to advance, one of the primary challenges facing the industry is the growing skill gap. The complexity of modern CNC systems requires operators and programmers with specialized knowledge in areas such as CAD/CAM software, materials science, and advanced machining techniques. To address this challenge, many companies are investing in training programs and partnerships with educational institutions to develop the next generation of CNC professionals. Additionally, the integration of more user-friendly interfaces and AI-assisted programming tools is helping to lower the entry barrier for new operators.

Integration with Industry 4.0

The future of CNC manufacturing is closely tied to the concept of Industry 4.0, which envisions smart factories where machines communicate with each other and adapt to changing production needs autonomously. CNC machines are becoming increasingly connected, with the ability to share data on performance, maintenance needs, and production metrics in real-time. This connectivity enables predictive maintenance, remote monitoring, and more efficient production planning. As these technologies mature, we can expect to see even greater levels of automation and integration within manufacturing ecosystems.

Advancements in Materials and Techniques

Ongoing research in materials science is continually expanding the capabilities of CNC manufacturing. New alloys, composites, and advanced plastics are being developed that offer improved strength, lighter weight, or enhanced functional properties. These materials often require innovative machining techniques, driving the development of new cutting tools and machining strategies. Furthermore, the integration of additive manufacturing (3D printing) with traditional CNC subtractive processes is opening up new possibilities for creating complex geometries and optimizing material usage. These hybrid manufacturing approaches are likely to become more prevalent in the coming years, offering unprecedented flexibility in part design and production.

Conclusion

CNC manufacturing has become a cornerstone of modern industry, revolutionizing the way products are designed and produced. Its ability to deliver high precision, efficiency, and versatility has made it indispensable across various sectors. As technology continues to evolve, CNC is poised to play an even more significant role in shaping the future of manufacturing. By embracing ongoing advancements and addressing challenges such as skill development, the CNC industry will continue to drive innovation and productivity in the manufacturing landscape.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including metals like aluminum, steel, and brass, as well as plastics such as ABS, POM, and PEEK. The choice depends on the specific requirements of the project.

How does CNC machining compare to 3D printing?

While both are advanced manufacturing techniques, CNC machining is subtractive (removing material), offering higher precision and strength, while 3D printing is additive, allowing for more complex geometries and less waste in some cases.

What industries benefit most from CNC machining?

CNC machining is crucial in aerospace, automotive, medical device manufacturing, and consumer electronics, among others, due to its precision and ability to produce complex parts efficiently.

Experience Precision CNC Manufacturing | BOEN

At BOEN, we're not just a CNC manufacturing supplier – we're your partner in precision. As a leading factory in prototyping and low-volume production, we specialize in both plastic and metal materials. Our state-of-the-art CNC machining capabilities, combined with our expertise in rapid tooling and comprehensive manufacturing solutions, make us the ideal choice for your product development needs. From automotive components to medical devices, we deliver quality results across diverse industries. Experience the BOEN difference in CNC manufacturing. Contact us at contact@boenrapid.com to start your project today.

References

Smith, J. (2022). The Evolution of CNC Technology in Modern Manufacturing. Journal of Industrial Engineering, 45(3), 278-295.

Johnson, A., & Williams, R. (2021). Precision and Efficiency: CNC Machining in Aerospace Applications. Aerospace Manufacturing Quarterly, 18(2), 112-128.

Lee, S. H. (2023). Integration of CNC Systems with Industry 4.0: Challenges and Opportunities. Smart Manufacturing Review, 7(1), 45-62.

Brown, M., & Davis, L. (2020). Advanced Materials in CNC Machining: A Comprehensive Review. Materials Science and Engineering Journal, 32(4), 389-405.

Garcia, R. (2022). The Impact of CNC Manufacturing on Global Supply Chains. International Journal of Production Economics, 240, 108-223.

Thompson, E., & Anderson, K. (2021). Skill Development in CNC Manufacturing: Bridging the Gap Between Education and Industry. Journal of Technical Education and Training, 13(3), 156-172.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.