Key Factors in Assessing Aerospace Precision Components Suppliers

Technical Expertise and Manufacturing Capabilities

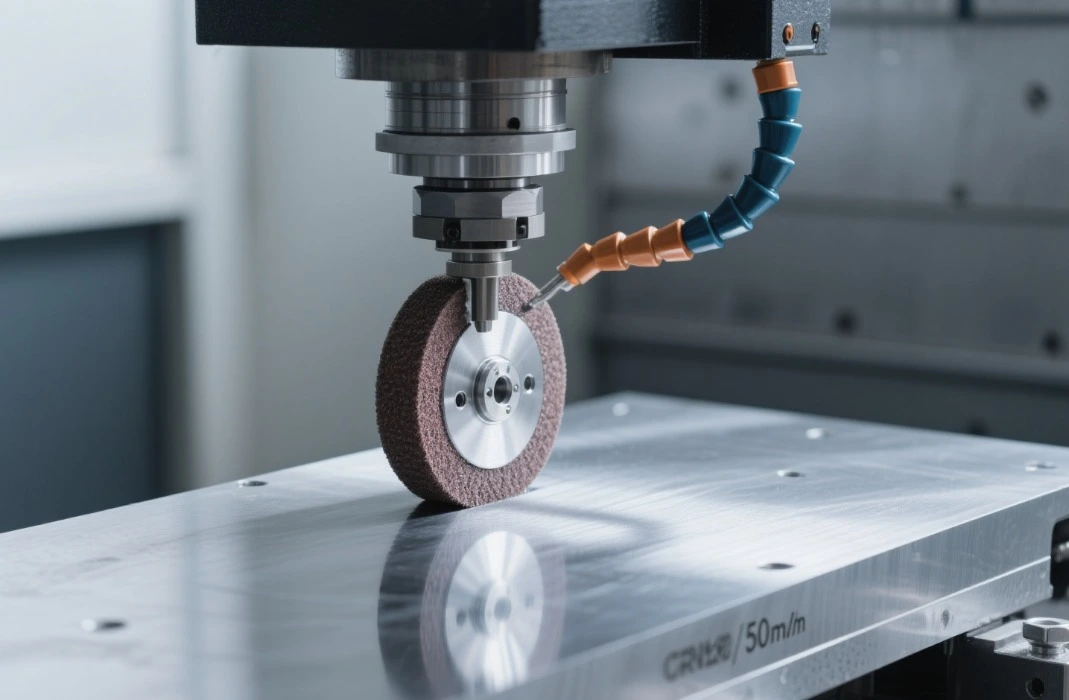

When evaluating aerospace precision components suppliers, technical expertise and manufacturing capabilities stand at the forefront of consideration. Suppliers must demonstrate proficiency in a wide array of advanced manufacturing techniques relevant to the aerospace industry. This includes mastery of CNC machining for creating complex geometries with tight tolerances, rapid injection molding for producing lightweight yet durable parts, and additive manufacturing technologies like SLA and SLS 3D printing for prototyping and small-batch production.

Moreover, suppliers should possess in-depth knowledge of aerospace-grade materials, including high-performance alloys, composites, and specialized plastics. Their ability to work with these materials to exacting specifications is crucial for ensuring the reliability and performance of critical aerospace components. Look for suppliers who have invested in state-of-the-art equipment and regularly update their manufacturing capabilities to stay ahead of industry advancements.

Additionally, assess the supplier's design for manufacturability (DFM) expertise. Skilled suppliers can offer valuable insights during the design phase, suggesting modifications that can improve part performance, reduce production costs, or enhance manufacturability without compromising quality or functionality. This collaborative approach can lead to more efficient production processes and superior end products.

Quality Management Systems and Certifications

The aerospace industry demands unwavering commitment to quality, given the critical nature of its aerospace precision components. When evaluating suppliers, scrutinize their quality management systems (QMS) and relevant certifications. The AS9100 certification is particularly important, as it is the quality standard specifically developed for the aerospace industry. This certification ensures that the supplier adheres to rigorous quality control processes throughout their entire operation.

Beyond AS9100, look for additional certifications that demonstrate the supplier's commitment to excellence, such as ISO 9001 for general quality management or NADCAP accreditations for specific processes like heat treatment or non-destructive testing. These certifications provide assurance that the supplier maintains consistent quality standards and continuously improves their processes.

Examine the supplier's quality control procedures, including their inspection methods, testing capabilities, and documentation practices. Advanced suppliers may employ cutting-edge quality assurance technologies like 3D scanning and computerized measurement systems to ensure precision and consistency. The ability to provide detailed quality reports and maintain thorough traceability records is also crucial in the aerospace industry.

Track Record and Industry Experience

A supplier's track record and industry experience offer valuable insights into their reliability and expertise. Investigate their history of working with aerospace clients, paying particular attention to long-term partnerships they may have established with major aerospace manufacturers or tier-one suppliers. These relationships often indicate a proven ability to meet the industry's demanding requirements consistently.

Request case studies or examples of past projects that showcase the supplier's capabilities in producing complex aerospace components. Look for evidence of their problem-solving skills, ability to meet tight deadlines, and success in handling challenging materials or intricate designs. A supplier with a diverse portfolio of aerospace projects demonstrates versatility and adaptability to various customer needs.

Consider the supplier's reputation within the industry. Seek references from other aerospace companies or consult industry associations for feedback. A supplier with a strong reputation for reliability, quality, and innovation is more likely to be a valuable long-term partner in your supply chain.

Assessing Production Capacity and Supply Chain Management

Production Scalability and Flexibility

When evaluating aerospace precision components suppliers, it's crucial to assess their production scalability and flexibility. The aerospace industry often requires suppliers to handle varying production volumes, from prototypes and small batches to larger-scale production runs. A versatile supplier should demonstrate the ability to efficiently scale their operations to meet fluctuating demand without compromising quality or lead times.

Examine the supplier's production facilities and equipment capacity. Do they have sufficient machinery and personnel to handle sudden increases in order volume? Look for suppliers who have invested in flexible manufacturing systems that can be quickly reconfigured for different product lines. This adaptability is particularly valuable in the aerospace sector, where component designs may evolve rapidly during development phases.

Additionally, consider the supplier's approach to capacity planning and resource allocation. Advanced suppliers often employ sophisticated production scheduling software and lean manufacturing principles to optimize their operations. This enables them to maximize efficiency and respond swiftly to changing customer requirements.

Supply Chain Resilience and Risk Management

The robustness of a supplier's supply chain is a critical factor in ensuring consistent delivery of aerospace precision components. Evaluate the supplier's approach to supply chain management, focusing on their strategies for mitigating risks and maintaining continuity of operations. A resilient supply chain is essential in an industry where component shortages or delays can have significant ripple effects throughout the entire production process.

Inquire about the supplier's sourcing practices for raw materials and sub-components. Do they have multiple qualified sources for critical materials? How do they manage inventory to buffer against supply disruptions? Look for suppliers who maintain strong relationships with their own suppliers and have contingency plans in place for potential supply chain interruptions.

Consider the supplier's geographical location and its potential impact on logistics and lead times. While global sourcing can offer cost advantages, it may also introduce complexities in terms of transportation, customs clearance, and compliance with international trade regulations. Assess whether the supplier has effective strategies for managing these challenges and ensuring timely delivery of components.

Technology Integration and Industry 4.0 Adoption

In today's rapidly evolving manufacturing landscape, a supplier's commitment to technology integration and Industry 4.0 principles can significantly enhance their capabilities and efficiency. When evaluating aerospace precision components suppliers, assess their level of digital transformation and adoption of smart manufacturing technologies.

Look for suppliers who have implemented advanced manufacturing execution systems (MES) that provide real-time visibility into production processes. These systems enable better quality control, improve traceability, and facilitate data-driven decision-making. Suppliers utilizing IoT sensors and data analytics to monitor equipment performance and predict maintenance needs demonstrate a proactive approach to ensuring production reliability.

Consider the supplier's use of digital twin technology for product development and process optimization. This advanced simulation capability can lead to faster design iterations, reduced physical prototyping costs, and improved overall product quality. Additionally, evaluate their adoption of collaborative technologies that facilitate seamless communication and data exchange with customers and partners throughout the supply chain.

Evaluating Customer Service and Long-term Partnership Potential

Responsiveness and Communication

The ability of an aerospace precision components supplier to communicate effectively and respond promptly to inquiries and issues is paramount. Evaluate their responsiveness during the initial engagement process as it often reflects their overall customer service approach. Look for suppliers who demonstrate a proactive communication style, providing regular updates on project status, potential challenges, and proposed solutions.

Assess the supplier's technical support capabilities. Do they have a dedicated team of engineers or technical specialists available to assist with design questions, material selection, or troubleshooting? The complexity of aerospace components often requires ongoing collaboration and technical dialogue. A supplier with strong technical support can become a valuable extension of your own engineering team.

Consider the supplier's communication infrastructure. Do they offer secure online portals for project management and document sharing? The ability to access real-time production data, quality reports, and delivery schedules can greatly enhance transparency and streamline collaboration. Suppliers who invest in these digital communication tools demonstrate a commitment to building strong, efficient partnerships with their customers.

Continuous Improvement and Innovation

In the rapidly evolving aerospace industry, a supplier's commitment to continuous improvement and innovation can be a significant differentiator. Evaluate their approach to staying current with industry trends, emerging technologies, and new manufacturing methodologies. Suppliers who actively engage in research and development activities or collaborate with academic institutions often bring fresh perspectives and cutting-edge solutions to the table.

Inquire about the supplier's investment in employee training and skill development. A workforce that is continuously upskilling to master new technologies and processes is better equipped to meet the evolving demands of aerospace manufacturing. Look for evidence of a culture that encourages innovation and problem-solving at all levels of the organization.

Consider the supplier's track record of introducing process improvements or innovative solutions that have benefited their customers. Have they developed proprietary technologies or unique manufacturing techniques that offer competitive advantages? Suppliers who demonstrate a forward-thinking approach and a willingness to push the boundaries of conventional manufacturing are more likely to be valuable long-term partners in driving innovation and efficiency in your supply chain.

Financial Stability and Long-term Viability

When evaluating aerospace precision components suppliers for long-term partnerships, assessing their financial stability and overall business viability is crucial. A supplier's financial health directly impacts their ability to invest in new technologies, maintain quality standards, and weather market fluctuations. Request financial statements or credit reports to gauge their financial strength and stability.

Examine the supplier's business diversification strategy. While specialization in aerospace components is important, a supplier with a diverse customer base across multiple industries may be better positioned to withstand sector-specific downturns. This diversification can contribute to their long-term stability and ensure continuity of supply even during challenging economic periods.

Consider the supplier's strategic vision and growth plans. Are they investing in expanding their capabilities or entering new markets? A supplier with a clear roadmap for future development is more likely to remain competitive and continue meeting your evolving needs. Look for indicators of sustainable business practices, including environmental initiatives and social responsibility programs, which are increasingly important in the aerospace industry and can impact long-term viability.

Conclusion

Evaluating aerospace precision components suppliers is a multifaceted process that requires careful consideration of technical capabilities, quality management, production capacity, and long-term partnership potential. By thoroughly assessing these key areas, aerospace companies can identify suppliers who not only meet current needs but also have the potential to grow and innovate alongside them. Remember that the best supplier relationships are built on a foundation of mutual trust, open communication, and shared commitment to excellence. Investing time in a comprehensive evaluation process will pay dividends in the form of reliable, high-quality components that contribute to the safety, performance, and success of aerospace projects.

FAQs

What certifications should I look for in an aerospace precision components supplier?

Key certifications include AS9100 for aerospace quality management, ISO 9001 for general quality standards, and NADCAP accreditations for specific processes.

How important is a supplier's experience in the aerospace industry?

Industry experience is crucial as it indicates familiarity with aerospace-specific requirements, materials, and regulations.

What role does technology play in selecting a supplier?

Advanced manufacturing technologies and Industry 4.0 adoption can significantly enhance a supplier's capabilities, efficiency, and quality control.

Expert Aerospace Precision Components Manufacturing | BOEN

At BOEN Prototype, we specialize in high-quality aerospace precision components manufacturing. Our state-of-the-art facilities, equipped with advanced CNC machining, rapid injection molding, and 3D printing technologies, ensure unparalleled precision and quality. As a trusted supplier and manufacturer in the aerospace industry, we offer comprehensive solutions from prototyping to low-volume production. Experience our expertise in crafting complex aerospace components with exacting tolerances. Contact us at contact@boenrapid.com to elevate your aerospace projects.

References

Johnson, A. (2023). "Quality Management Systems in Aerospace Manufacturing: A Comprehensive Guide." Aerospace Engineering Journal, 45(2), 112-128.

Smith, R. & Brown, T. (2022). "Evaluating Supplier Capabilities for Aerospace Precision Components." International Journal of Aerospace Supply Chain Management, 18(3), 301-315.

Thompson, E. (2023). "Industry 4.0 Technologies in Aerospace Manufacturing: Current Trends and Future Prospects." Journal of Advanced Manufacturing Technologies, 29(4), 587-602.

Lee, S. et al. (2022). "Supply Chain Resilience Strategies for Aerospace Component Manufacturers." Supply Chain Management Review, 14(2), 78-92.

Garcia, M. & Wilson, K. (2023). "Innovation and Continuous Improvement in Aerospace Precision Manufacturing." Aerospace Technology Review, 37(1), 45-59.

Anderson, P. (2022). "Financial Stability Assessment of Aerospace Suppliers: Metrics and Methodologies." Journal of Aerospace Business Management, 25(3), 210-224.