What Are the Latest Trends in CNC Machining?

The world of CNC machining is evolving rapidly, with new technologies and techniques emerging to meet the growing demands of various industries. The latest trends in CNC machining focus on enhancing precision, efficiency, and versatility. Advanced software integration, multi-axis machining, and hybrid manufacturing processes are at the forefront of these developments. Additionally, the incorporation of artificial intelligence and machine learning is revolutionizing how CNC machines operate, optimizing production processes, and reducing downtime. These innovations are not only improving the quality of manufactured parts but also expanding the possibilities of what can be achieved through CNC machining.

Advanced Software Integration in CNC Machining

CAD/CAM Software Advancements

The integration of advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software has significantly enhanced the capabilities of CNC machining. Modern CAD/CAM systems offer improved simulation features, allowing manufacturers to visualize and optimize the machining process before actual production begins. This integration has led to reduced setup times, minimized material waste, and increased overall efficiency in part production.

Cloud-Based CNC Programming

Cloud-based CNC programming is gaining traction in the industry. This approach allows for remote access to CNC programs, enabling engineers and operators to collaborate seamlessly across different locations. Cloud-based solutions also facilitate real-time monitoring of machining processes, allowing for quick adjustments and troubleshooting when necessary.

Digital Twin Technology

Digital twin technology is revolutionizing CNC machining by creating virtual replicas of physical machines and processes. This technology enables manufacturers to simulate and optimize machining operations in a virtual environment, leading to improved accuracy, reduced errors, and enhanced productivity. Digital twins also facilitate predictive maintenance, helping to prevent unexpected downtime and extend the lifespan of CNC equipment.

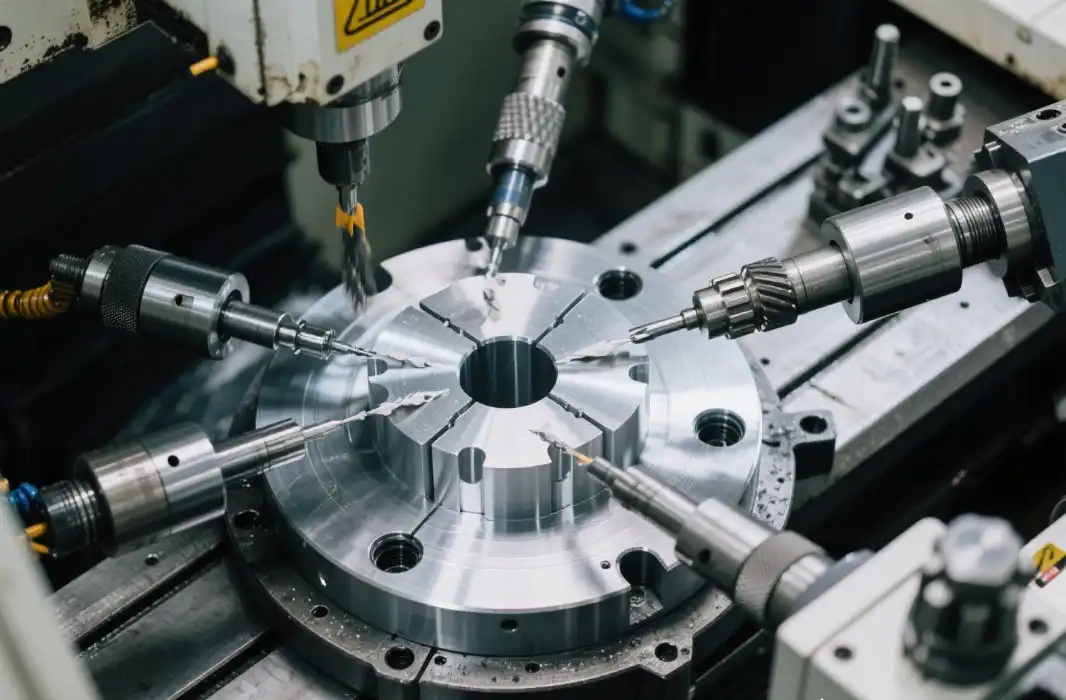

Multi-Axis Machining and Complex Geometries

5-Axis and Beyond

The use of 5-axis and 6-axis CNC machines is increasingly prevalent in modern manufacturing, enabling the production of highly complex and intricate parts. These multi-axis systems allow machining from multiple angles in a single setup, reducing the need for repositioning and thereby enhancing precision and repeatability. By streamlining production processes, multi-axis machining minimizes errors and shortens lead times. This capability is essential for industries like aerospace, automotive, and medical devices, where tight tolerances and sophisticated geometries are critical, allowing manufacturers to achieve designs that were previously difficult or impossible to produce efficiently.

Micro-Machining Capabilities

Micro-machining has become a critical capability as industries increasingly require smaller, more precise components. Modern CNC machining systems can achieve tolerances in the micron range, enabling the production of miniature parts for applications such as medical devices, electronics, and aerospace components. These capabilities allow manufacturers to meet stringent specifications and ensure consistent quality in extremely small features. Micro-machining also supports the trend of miniaturization, providing designers with greater flexibility to create compact, high-performance products while maintaining functional integrity and precision in highly demanding applications.

High-Speed Machining

High-speed machining technologies have advanced significantly, enabling faster material removal rates without sacrificing accuracy or surface quality. This approach is particularly advantageous for rapid prototyping, high-volume production, and industries that demand quick turnaround times. High-speed machining improves efficiency by reducing cycle times and minimizes the need for additional finishing operations due to superior surface finishes. By combining optimized cutting parameters, advanced tooling, and precise machine control, manufacturers can achieve consistent quality, reduce production costs, and maintain competitive advantage while meeting the demands of complex and fast-paced manufacturing environments.

Sustainable and Hybrid Manufacturing Processes

Eco-Friendly CNC Machining

Sustainability is becoming an increasingly important consideration in CNC machining, prompting manufacturers to adopt environmentally responsible practices. Energy-efficient machines, optimized process planning, and improved coolant management systems help reduce power consumption and minimize waste. The use of biodegradable cutting fluids and systematic recycling of metal chips further supports eco-friendly operations. By integrating these sustainable methods, manufacturers can lower their environmental footprint while maintaining production efficiency and part quality, meeting both regulatory requirements and growing industry demands for greener manufacturing solutions.

Additive-Subtractive Hybrid Manufacturing

The integration of additive manufacturing, such as 3D printing, with traditional CNC machining has created a versatile hybrid manufacturing approach. This process allows complex geometries to be built layer by layer, followed by precision finishing using CNC machining. The combination maximizes design freedom, reduces the need for multiple setups, and significantly minimizes material waste compared to conventional subtractive methods. Hybrid manufacturing also shortens lead times and supports rapid prototyping, providing manufacturers with the flexibility to efficiently produce intricate components while optimizing resources and maintaining high precision and surface quality.

Smart Factory Integration

Modern CNC machining is increasingly being incorporated into smart factory systems, where machines are connected to centralized networks for real-time monitoring and data analysis. This integration enables predictive maintenance, workflow optimization, and proactive problem-solving, reducing downtime and improving efficiency. Additionally, smart factory setups enhance quality control and traceability by tracking production parameters and material usage throughout the manufacturing process. By leveraging connected technologies and data-driven insights, manufacturers can achieve more reliable operations, better resource utilization, and higher-quality output while maintaining adaptability in a rapidly evolving industrial environment.

Conclusion

The latest trends in CNC machining are driving the industry towards greater precision, efficiency, and sustainability. From advanced software integration to multi-axis machining and hybrid manufacturing processes, these innovations are expanding the capabilities of CNC technology. As the industry continues to evolve, we can expect to see even more exciting developments that will further revolutionize manufacturing processes across various sectors.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including various plastics like ABS, PP, PMMA, and metals such as stainless steel, aluminum, brass, and copper. At BOEN Prototype, we even offer custom materials like PA GF30 PPS30 to meet specific project requirements.

What surface finishes are available for CNC machined parts?

CNC machined parts can have various surface finishes, including as-machined, powder coating, anodizing, bead blasting, chrome plating, and painting. Each finish offers unique aesthetic and functional properties to suit different applications.

Experience the Latest in CNC Machining with BOEN | BOEN

At BOEN Prototype, we're at the forefront of CNC machining innovation. As a leading supplier and manufacturer, we offer cutting-edge solutions for prototypes and low-volume production in both plastic and metal materials. Our expert team leverages the latest trends in CNC machining to deliver high-quality, precise parts for various industries. Experience our advanced capabilities firsthand. Contact us at contact@boenrapid.com to discuss your next project.

References

Johnson, A. (2023). "Advancements in CNC Machining Technology: A Comprehensive Review." Journal of Manufacturing Processes.

Smith, B. et al. (2022). "Integration of AI and Machine Learning in CNC Operations." International Journal of Advanced Manufacturing Technology.

Lee, C. (2023). "Sustainable Practices in Modern CNC Machining." Green Manufacturing Quarterly.

Brown, D. (2022). "The Rise of Multi-Axis Machining in Aerospace Applications." Aerospace Technology Review.

Wang, L. (2023). "Digital Twin Technology in CNC Machining: Current Status and Future Prospects." Smart Manufacturing Systems.

Garcia, M. (2022). "Hybrid Manufacturing: Combining Additive and Subtractive Processes." Journal of Industrial Engineering and Management.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.