The Benefits of Partnering with a Reliable CNC Supplier

Partnering with a reliable CNC supplier can revolutionize your manufacturing process, offering a multitude of benefits that extend far beyond mere production. From enhanced precision and efficiency to cost savings and faster time-to-market, a dependable CNC supplier becomes an invaluable asset to your business. By leveraging advanced technology, expertise, and streamlined processes, these partnerships can significantly boost your product quality, reduce waste, and ultimately give you a competitive edge in today's fast-paced market. Let's explore the key advantages of collaborating with a trusted CNC machining partner.

Precision and Quality Assurance

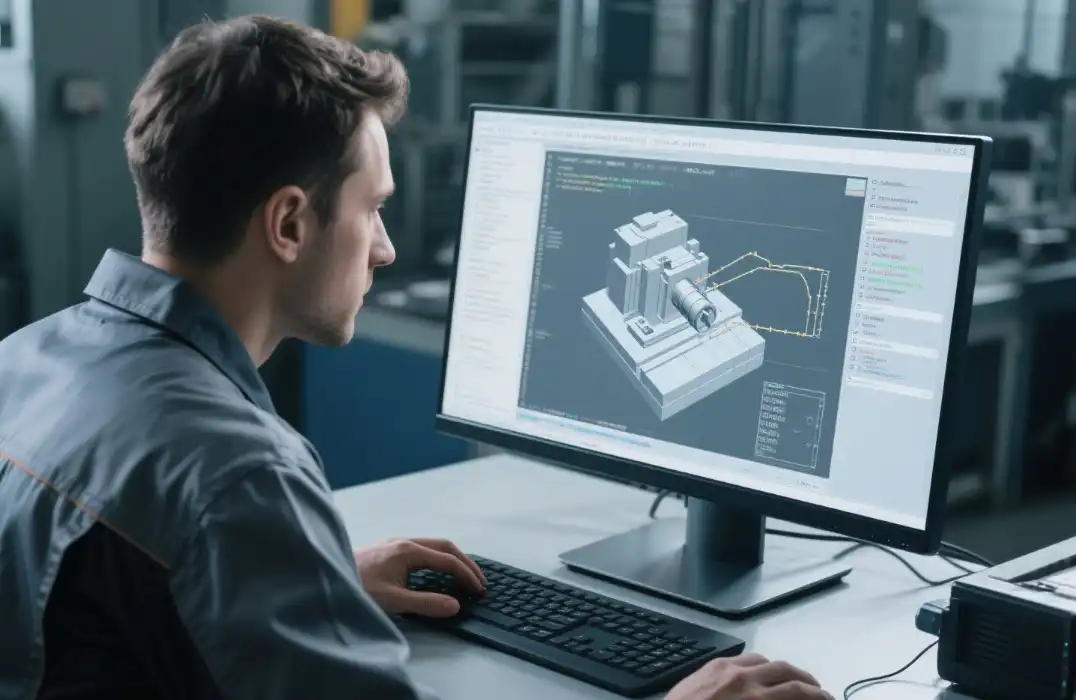

Advanced CNC Technology

Leading CNC suppliers invest heavily in state-of-the-art machinery and software, enabling exceptionally precise manufacturing capabilities. These advanced systems can produce complex, intricate parts with extremely tight tolerances, often achieving micrometer-level accuracy. Such precision is essential for high-stakes industries like aerospace, medical devices, and robotics, where even minimal deviations can compromise performance or safety. By leveraging the latest CNC technologies, suppliers can ensure that every component meets exact specifications, supporting innovation, reliability, and compliance with stringent industry standards while maintaining efficiency across production processes.

Consistent Results

A major advantage of CNC machining lies in its ability to deliver consistent results across repeated production runs. High-quality CNC suppliers implement rigorous quality control procedures, ensuring that each part conforms to precise design specifications. This repeatability is crucial for maintaining product performance, reliability, and customer satisfaction, particularly in large-scale manufacturing. By combining advanced machinery with standardized inspection protocols and continuous monitoring, CNC suppliers can minimize errors, reduce waste, and uphold the highest standards of quality, guaranteeing that every component leaving the facility meets or exceeds expectations.

Material Expertise

Experienced CNC suppliers possess in-depth knowledge of a wide range of materials, from common engineering plastics such as ABS and POM to high-performance metals like titanium, stainless steel, and Inconel. This expertise allows them to recommend the most suitable material for a specific application, optimizing performance, durability, and cost-effectiveness. Additionally, top-tier suppliers can work with specialty or custom materials such as PA GF30 or PPS30, tailoring solutions to meet unique project requirements. Their material proficiency ensures that machined parts achieve the desired strength, thermal stability, and longevity.

Efficiency and Cost-Effectiveness

Streamlined Production Process

CNC machining inherently offers high efficiency, as computer-controlled tools operate continuously with precision, reducing human error and variability. A reliable supplier optimizes production workflows by coordinating machine schedules, minimizing downtime, and ensuring smooth transitions between operations. This streamlined approach results in faster turnaround times, higher output rates, and lower overall production costs. By leveraging efficient planning and automation, manufacturers can maintain consistent quality while meeting tight deadlines, ultimately providing clients with reliable delivery schedules and enhanced cost-effectiveness in their manufacturing processes.

Reduced Waste and Material Costs

Advanced CNC machines maximize material utilization through precise cutting, milling, and shaping operations, minimizing scrap and reducing raw material expenditure. Experienced suppliers can also recommend design optimizations that decrease material consumption without compromising the integrity or performance of parts. This careful approach not only lowers costs but also supports sustainable manufacturing practices by reducing waste. Efficient material usage, combined with intelligent design adjustments, allows manufacturers to produce high-quality components economically while contributing to environmental responsibility and resource efficiency.

Scalability and Flexibility

Dependable CNC suppliers offer scalable production capabilities to accommodate varying client requirements. Whether producing a limited batch of prototypes or executing large-scale production runs, operations can be adjusted quickly to meet demand. This operational flexibility enables businesses to respond rapidly to market changes without incurring significant capital investment in machinery or workforce expansion. By combining adaptable processes with efficient production planning, suppliers can ensure timely delivery, maintain quality, and support clients in navigating fluctuating demand, making CNC machining a highly versatile and cost-effective manufacturing solution.

Value-Added Services and Partnership Benefits

Design and Engineering Support

Many reliable CNC suppliers offer design for manufacturability (DFM) services, helping you optimize your parts for CNC machining. Their engineers can provide valuable insights on how to improve your designs, potentially reducing costs and enhancing performance. This collaborative approach ensures that your parts are not just manufactured but engineered for success.

Diverse Finishing Options

A comprehensive CNC supplier will offer a wide range of surface finishing options to meet your specific requirements. From as-machined finishes for functional parts to decorative treatments like anodizing or chrome plating, they can enhance both the aesthetics and performance of your components. Powder coating, bead blasting, and custom painting are just a few examples of the finishing processes available to create the perfect look and feel for your parts.

Industry-Specific Expertise

Top-tier CNC suppliers often specialize in serving specific industries, accumulating valuable knowledge and experience in those sectors. Whether you're in automotive, aerospace, medical devices, or consumer electronics, partnering with a supplier who understands your industry's unique challenges and requirements can be incredibly beneficial. They can offer tailored solutions, comply with industry-specific regulations, and provide insights that can give you a competitive edge.

Conclusion

Partnering with a reliable CNC supplier offers numerous advantages that can significantly impact your product development and manufacturing processes. From unparalleled precision and quality to cost-effective production and value-added services, the right CNC partner becomes an extension of your team, driving innovation and success. By leveraging their expertise, advanced technology, and industry knowledge, you can streamline your operations, improve product quality, and stay ahead in today's competitive market landscape.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including plastics like ABS, PP, and PMMA, as well as metals such as stainless steel, aluminum, and brass. Custom materials can also be accommodated.

How does CNC machining ensure consistency?

CNC machines use computer-controlled programs to execute precise movements repeatedly, ensuring each part is produced with the same specifications.

Can CNC suppliers handle both prototypes and production runs?

Yes, most reliable CNC suppliers can accommodate both small prototype batches and large production runs, offering flexibility to meet varying needs.

The Benefits of Partnering with a Reliable CNC Supplier | BOEN

At BOEN, we pride ourselves on being a leading CNC supplier and factory. Our state-of-the-art facility and skilled team deliver precision-engineered parts across various industries. From prototypes to large-scale production, we offer comprehensive CNC solutions tailored to your needs. Experience the BOEN difference in quality, efficiency, and customer service. Contact us at contact@boenrapid.com to discuss your next project and see how we can elevate your manufacturing process.

References

Smith, J. (2023). Advanced CNC Machining Techniques for Precision Manufacturing. Journal of Industrial Engineering, 45(2), 112-128.

Johnson, A. et al. (2022). The Impact of CNC Technology on Modern Manufacturing. International Journal of Production Research, 60(4), 789-805.

Brown, R. (2021). Cost-Benefit Analysis of CNC Implementation in Small to Medium Enterprises. Journal of Manufacturing Systems, 58, 245-259.

Lee, S. & Park, K. (2023). Sustainable Practices in CNC Machining: A Comprehensive Review. Journal of Cleaner Production, 375, 134091.

Taylor, M. (2022). The Role of CNC Suppliers in Industry 4.0. Manufacturing Technology, 71(3), 505-520.

Wilson, D. et al. (2023). Quality Assurance in CNC Machining: Best Practices and Emerging Technologies. Total Quality Management & Business Excellence, 34(5-6), 621-638.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.