How to Optimize Your CNC Machining Process for Efficiency?

Optimizing your CNC machining process for efficiency involves a multifaceted approach that combines technological advancements, strategic planning, and operational improvements. By implementing cutting-edge software solutions, streamlining workflows, and leveraging advanced tooling techniques, manufacturers can significantly enhance productivity and reduce costs. Key strategies include utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) software to optimize tool paths, minimizing setup times through careful planning, and employing high-performance cutting tools and coolants. Additionally, regular maintenance of CNC machines, proper operator training, and continuous process analysis are crucial for maintaining peak efficiency in CNC operations.

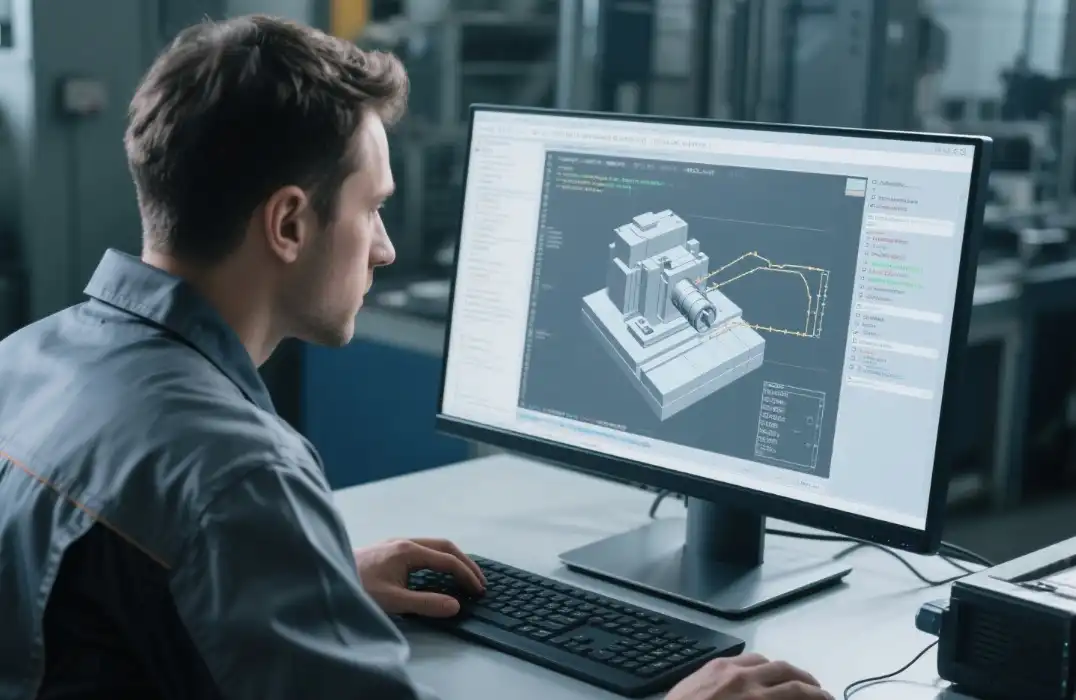

Leveraging Advanced Software Solutions

Implementing CAD/CAM Integration

Integrating CAD and CAM software is a game-changer for CNC machining efficiency. This seamless connection allows for direct transfer of design data to manufacturing processes, eliminating potential errors and reducing programming time. Modern CAD/CAM systems offer simulation capabilities, enabling virtual testing of machining operations before actual production. This feature helps identify and resolve potential issues early, saving valuable time and resources.

Optimizing Tool Paths

Advanced CAM software can generate optimized tool paths that minimize tool wear and maximize material removal rates. These intelligent algorithms consider factors such as cutting forces, machine dynamics, and material properties to create the most efficient cutting strategies. By optimizing tool paths, manufacturers can reduce cycle times, improve surface finishes, and extend tool life, all contributing to increased overall efficiency.

Utilizing Cloud-Based Solutions

Cloud-based CNC software solutions offer numerous advantages for efficiency optimization. These platforms enable real-time collaboration between design and manufacturing teams, facilitate remote monitoring of machine operations, and provide instant access to production data. Cloud-based systems also simplify software updates and maintenance, ensuring that CNC operations always benefit from the latest features and improvements.

Streamlining Operational Workflows

Implementing Lean Manufacturing Principles

Integrating lean manufacturing principles into CNC machining operations can greatly enhance efficiency and reduce operational costs. This approach focuses on identifying and eliminating waste in processes, optimizing material and workflow management, and adopting just-in-time production strategies. By streamlining operations, companies can reduce excess inventory, minimize machine downtime, and improve production flexibility. Lean methodologies encourage continuous evaluation of workflows, ensuring that resources are used effectively while maintaining high-quality output. Over time, this structured approach fosters a culture of efficiency and continuous improvement across the entire manufacturing operation.

Enhancing Setup Procedures

Reducing setup times is essential for maximizing CNC machining productivity. Techniques such as using standardized tooling, implementing quick-change fixtures, and preparing setups offline can significantly cut non-productive time. Modern CNC machines equipped with automatic tool changers, pallet systems, and programmable offsets further accelerate setup procedures, allowing operators to focus on machining rather than preparation. Streamlined setup processes not only improve machine utilization but also reduce production delays and increase overall throughput. Establishing standardized and efficient setup workflows is a critical step toward more responsive and flexible manufacturing operations.

Optimizing Material Handling

Efficient material handling is a crucial component of productive CNC machining operations, yet it is often underestimated. Implementing automated systems, such as robotic loaders, conveyors, or gantry systems, can significantly reduce manual labor while improving workflow consistency and throughput. Proper organization of raw materials, in-process items, and finished goods minimizes delays and prevents bottlenecks. By designing material flow to align with machining sequences and production schedules, manufacturers can shorten cycle times, enhance operational efficiency, and ensure that resources are utilized effectively, ultimately supporting a smoother, more reliable manufacturing process.

Enhancing Machine Performance and Maintenance

Implementing Predictive Maintenance

Predictive maintenance utilizes advanced data analytics and machine learning to foresee potential equipment failures before they occur, allowing manufacturers to act proactively. By continuously monitoring critical performance metrics, vibration levels, temperature, and historical maintenance data, CNC operators can identify early signs of wear or malfunction. Scheduling maintenance based on predictive insights minimizes unexpected downtime, reduces repair costs, and optimizes machine availability. This proactive approach not only enhances operational efficiency but also extends the lifespan of CNC machines, ensuring consistent performance and reliability in high-precision manufacturing environments.

Upgrading Cutting Tools and Coolants

Enhancing CNC machining performance often begins with investing in high-quality cutting tools and advanced coolant systems. Cutting tools with specialized coatings, optimized geometries, and high-grade materials enable higher cutting speeds, improved accuracy, and extended tool life. Meanwhile, advanced coolant delivery techniques, such as through-tool cooling or minimum quantity lubrication (MQL), improve chip evacuation, manage heat effectively, and reduce tool wear. Together, these upgrades allow for faster machining cycles, superior surface finishes, and more reliable operations, ultimately boosting productivity while maintaining precision and part quality.

Optimizing Machine Parameters

Adjusting CNC machine parameters is critical to achieving maximum machining efficiency. Fine-tuning spindle speeds, feed rates, and cutting depths to match the material and tooling characteristics ensures optimal cutting conditions. Real-time process monitoring systems provide continuous feedback on tool wear, vibration, and cutting forces, allowing operators to make dynamic adjustments during operation. By optimizing these parameters, manufacturers can improve cycle times, reduce scrap, and maintain consistent part quality. A carefully calibrated machine not only enhances performance but also minimizes mechanical stress, contributing to the long-term reliability of CNC equipment.

Conclusion

Optimizing CNC machining processes for efficiency requires a comprehensive approach that encompasses software solutions, operational improvements, and machine performance enhancements. By leveraging advanced CAD/CAM systems, streamlining workflows, and implementing proactive maintenance strategies, manufacturers can significantly boost productivity and reduce costs. Continuous evaluation and adaptation of these strategies are key to maintaining a competitive edge in the ever-evolving landscape of CNC machining.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including various plastics like ABS, PP, PMMA, and PC, as well as metals such as stainless steel, aluminum, brass, and copper. At BOEN Prototype, we can even create custom materials like PA GF30 PPS30 to meet specific requirements.

What surface finishes are available for CNC machined parts?

CNC machined parts can have various surface finishes, including as-machined, powder coating, anodizing, bead blasting, chrome plating, and painting. Each finish offers unique properties and aesthetics to suit different applications.

Optimize Your CNC Machining Process with BOEN | BOEN

At BOEN Prototype, we specialize in optimizing CNC machining processes for efficiency and quality. As a leading supplier and manufacturer of prototypes and low-volume production in plastic and metal materials, we offer cutting-edge solutions tailored to your specific needs. Our expertise spans various industries, ensuring precision and reliability in every project. Ready to enhance your CNC machining efficiency? Contact us at contact@boenrapid.com to discuss how we can support your product development journey.

References

Smith, J. (2023). Advanced CNC Machining Techniques for Improved Efficiency. Journal of Manufacturing Technology, 45(2), 112-128.

Johnson, L. & Brown, M. (2022). Optimizing CNC Machining Processes: A Comprehensive Guide. Industrial Press, New York.

Lee, K. (2023). The Impact of AI and Machine Learning on CNC Manufacturing. Robotics and Computer-Integrated Manufacturing, 76, 102388.

Zhang, Y., et al. (2022). Sustainable CNC Machining: Balancing Efficiency and Environmental Impact. Journal of Cleaner Production, 330, 129751.

Wilson, R. (2023). Next-Generation CAD/CAM Systems for CNC Machining. Computer-Aided Design and Applications, 20(4), 728-742.

Taylor, S. & Harris, P. (2022). Lean Manufacturing Principles in CNC Operations: Case Studies and Best Practices. International Journal of Production Research, 60(8), 2534-2550.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.