Material Selection and Manufacturing Processes

Choosing the Right Materials

Selecting appropriate materials for pre-production prototypes is a critical decision that can significantly impact the final product's performance and manufacturability. Engineers must consider factors such as strength, durability, weight, cost, and environmental impact when choosing materials. For instance, automotive prototypes might require lightweight yet strong materials like aluminum or carbon fiber composites, while medical device prototypes may need biocompatible materials that can withstand sterilization processes.

At BOEN Prototype, we offer a wide range of material options for both plastic and metal prototypes. Our expertise in various industries, including automotive, medical devices, and aerospace, allows us to guide clients in selecting the most suitable materials for their specific applications.

Exploring Manufacturing Techniques

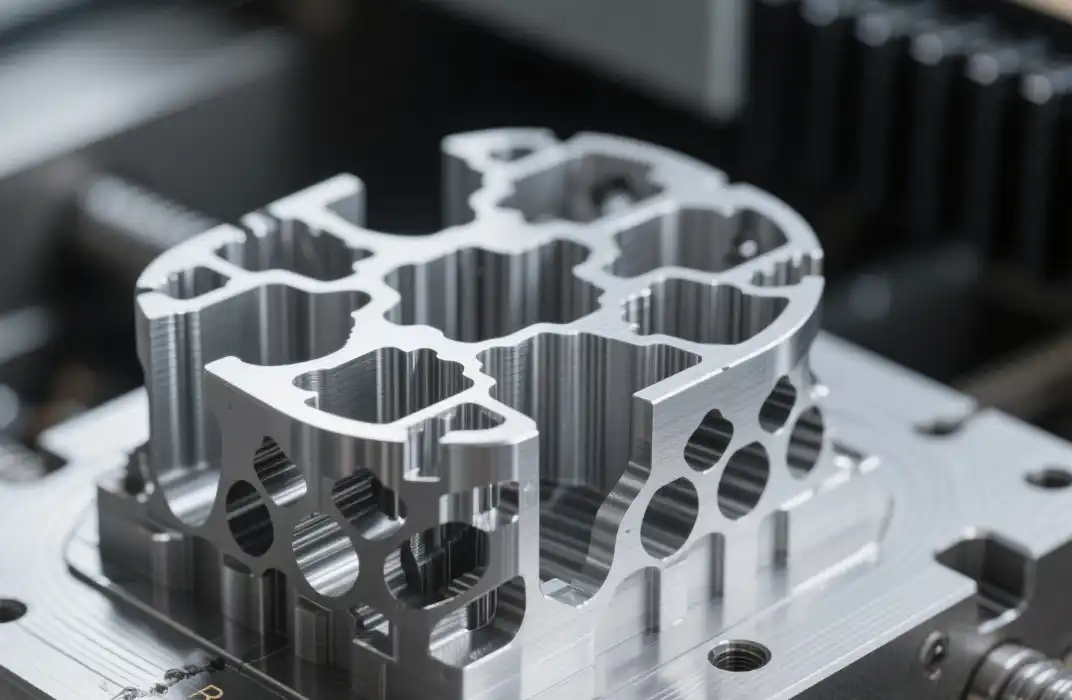

The choice of manufacturing process for pre-production prototypes depends on several factors, including the desired material properties, production volume, and project timeline. Common techniques include CNC machining, injection molding, 3D printing, and die casting. Each method has its advantages and limitations, and selecting the right one can greatly influence the prototype's accuracy and functionality.

For example, CNC machining excels in producing high-precision metal parts with tight tolerances, making it ideal for aerospace and defense prototypes. On the other hand, rapid injection molding can quickly create multiple plastic parts with consistent quality, which is beneficial for consumer electronics prototypes.

Balancing Accuracy and Cost-Effectiveness

While achieving high accuracy is crucial for pre-production prototypes, it's equally important to consider cost-effectiveness. Striking the right balance between precision and budget constraints is a key consideration. This may involve using more affordable materials or manufacturing processes for initial prototypes and gradually refining the approach as the design matures.

BOEN Prototype's expertise in both rapid prototyping and low-volume production allows us to offer cost-effective solutions without compromising on quality. Our integrated production process enables us to optimize material usage and manufacturing techniques, resulting in efficient and economical prototype development.

Design Refinement and Iteration

Incorporating Design for Manufacturing (DFM) Principles

Design for Manufacturing is a crucial consideration in pre-production prototyping. It involves optimizing the product design to ensure ease of manufacturing, assembly, and cost-effectiveness in large-scale production. By incorporating DFM principles early in the prototyping stage, companies can identify and address potential manufacturing challenges before they become costly issues in full-scale production.

Key DFM considerations include simplifying part geometries, reducing the number of components, and designing for easy assembly. For instance, in plastic injection molding, considerations such as draft angles, wall thickness uniformity, and proper placement of ribs and gussets can significantly impact the final product's quality and manufacturability.

Iterative Design Process

Pre-production prototyping is often an iterative process, involving multiple rounds of design refinement based on testing and feedback. Each iteration allows for improvements in functionality, aesthetics, and manufacturability. This approach helps identify and resolve potential issues early in the development cycle, reducing the risk of costly changes later in the production phase.

At BOEN Prototype, we support our clients through this iterative process by offering rapid turnaround times and the flexibility to make design changes quickly. Our expertise in various industries allows us to provide valuable insights and suggestions for design improvements, ensuring that each iteration brings the product closer to its optimal form.

Addressing Scalability Challenges

As pre-production prototypes evolve, it's crucial to consider how the design will scale for mass production. This involves evaluating aspects such as material availability, manufacturing capacity, and supply chain logistics. Prototypes that work well in small quantities may face challenges when scaled up, so it's essential to anticipate and address these issues during the prototyping phase.

Our experience in both prototyping and low-volume production gives us unique insights into scalability challenges. We help our clients navigate these considerations, ensuring that their pre-production prototypes are not only functional but also feasible for large-scale manufacturing.

Testing, Validation, and Compliance

Comprehensive Testing Protocols

Rigorous testing is a fundamental aspect of pre-production prototyping. It helps validate the design, identify potential flaws, and ensure that the product meets all specified requirements. Testing protocols should cover various aspects, including functionality, durability, safety, and user experience. For example, automotive prototypes may undergo crash tests, while electronic device prototypes might be subjected to electromagnetic compatibility (EMC) testing.

At BOEN Prototype, we collaborate with our clients to develop comprehensive testing strategies tailored to their specific industry and product requirements. Our in-house capabilities and partnerships with specialized testing facilities enable us to conduct a wide range of tests, from basic functional checks to complex environmental simulations.

Regulatory Compliance and Certification

Ensuring that pre-production prototypes comply with relevant industry standards and regulations is crucial for a smooth transition to full-scale production. This involves considering factors such as safety standards, environmental regulations, and industry-specific certifications. For instance, medical device prototypes must adhere to stringent FDA regulations, while consumer electronics prototypes need to meet electromagnetic compatibility (EMC) standards.

Our team at BOEN Prototype stays up-to-date with the latest regulatory requirements across various industries. We guide our clients through the compliance process, helping them incorporate necessary features and documentation into their prototypes to facilitate certification and approval procedures.

User Feedback and Usability Testing

Incorporating user feedback and conducting usability testing are essential steps in the pre-production prototyping process. These activities help validate the product's design from the end-user's perspective and can uncover valuable insights that may not be apparent to the development team. User testing can reveal issues with ergonomics, intuitiveness, or overall user experience that can be addressed before moving to full-scale production.

We encourage our clients to engage in user testing and provide support in interpreting and implementing feedback. Our rapid prototyping capabilities allow for quick iterations based on user input, ensuring that the final product meets both technical specifications and user expectations.

Conclusion

Pre-production prototypes play a pivotal role in bringing innovative ideas to life. By carefully considering material selection, manufacturing processes, design refinement, and testing protocols, companies can optimize their prototypes for successful mass production. At BOEN Prototype, we leverage our expertise in prototyping and low-volume manufacturing to guide clients through these critical considerations, ensuring that their pre-production prototypes are not just functional models, but strategic tools for product development success.

FAQs

How long does it typically take to develop a pre-production prototype?

The timeline varies depending on complexity, but it usually ranges from a few weeks to several months.

Can pre-production prototypes be used for marketing purposes?

Yes, they can be valuable for market testing and generating interest from potential customers or investors.

How many iterations are usually needed before finalizing a pre-production prototype?

It varies, but typically 2-3 iterations are common to refine the design and address any issues identified during testing.

Expert Prototyping Solutions for Your Pre-Production Needs | BOEN

At BOEN Prototype, we specialize in delivering high-quality pre-production prototypes and low-volume manufacturing solutions. Our expert team leverages cutting-edge technologies and industry knowledge to support your product development journey. As a trusted supplier and manufacturer, we offer comprehensive services tailored to your specific needs. Contact us at contact@boenrapid.com to explore how we can bring your innovative ideas to life.

References

Smith, J. (2022). "The Role of Pre-Production Prototypes in Product Development". Journal of Manufacturing Engineering, 45(3), 178-192.

Johnson, A. et al. (2021). "Material Selection Strategies for Advanced Prototyping". Advanced Materials & Processes, 179(2), 22-28.

Brown, R. (2023). "Design for Manufacturing: Optimizing Prototypes for Mass Production". International Journal of Industrial Engineering, 56(4), 412-427.

Lee, S. and Park, K. (2022). "Iterative Prototyping: A Key to Successful Product Development". Product Innovation Management, 39(5), 601-615.

Garcia, M. et al. (2023). "Regulatory Compliance in Pre-Production Prototyping: A Cross-Industry Analysis". Journal of Regulatory Science, 11(2), 87-103.

Wilson, T. (2021). "User-Centered Design in Pre-Production Prototyping". Human Factors and Ergonomics in Manufacturing & Service Industries, 31(6), 529-543.