The Science Behind Laser Engraving Technology

Understanding Laser Beam Characteristics

Laser engraving relies on high-powered beams of light to etch designs onto metal surfaces. These beams are focused through a series of lenses and mirrors, concentrating their energy into a tiny spot. The intensity of the laser beam can be adjusted to suit different metal types and desired engraving depths. This precision control allows for remarkable accuracy in creating both shallow and deep engravings.

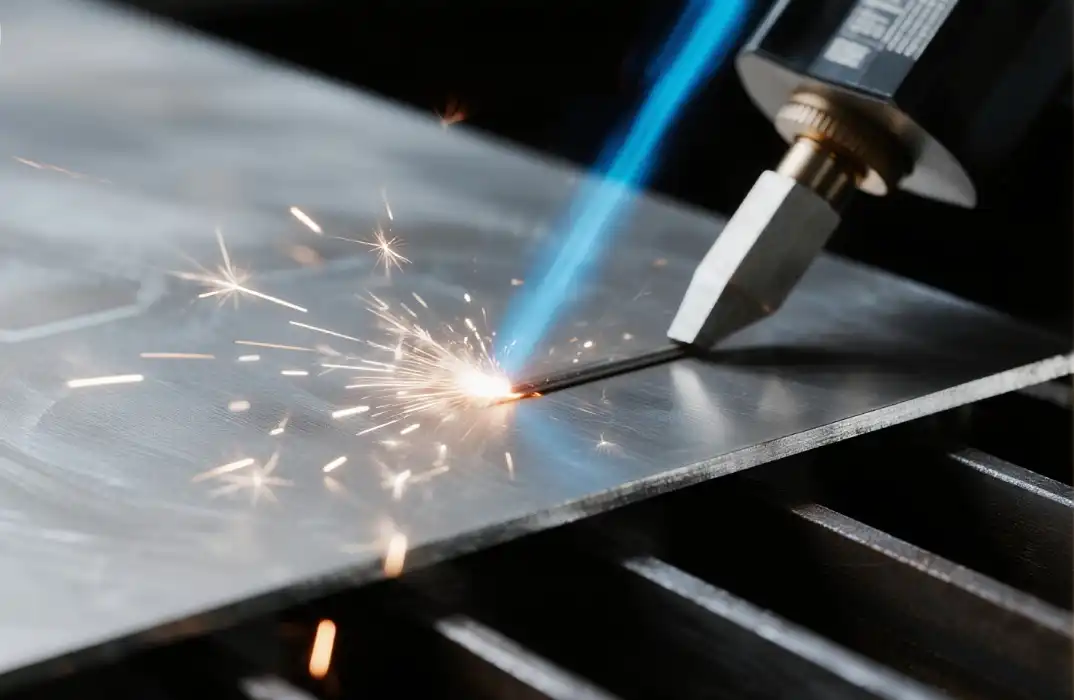

Heat-Affected Zone and Material Interaction

When the laser beam contacts the metal surface during laser cutting, it generates intense heat, causing the material to vaporize or melt. This process creates what's known as the heat-affected zone (HAZ). The size of the HAZ varies depending on the laser power, pulse duration, and material properties. Understanding these interactions is crucial for achieving optimal results in custom metal fabrication projects.

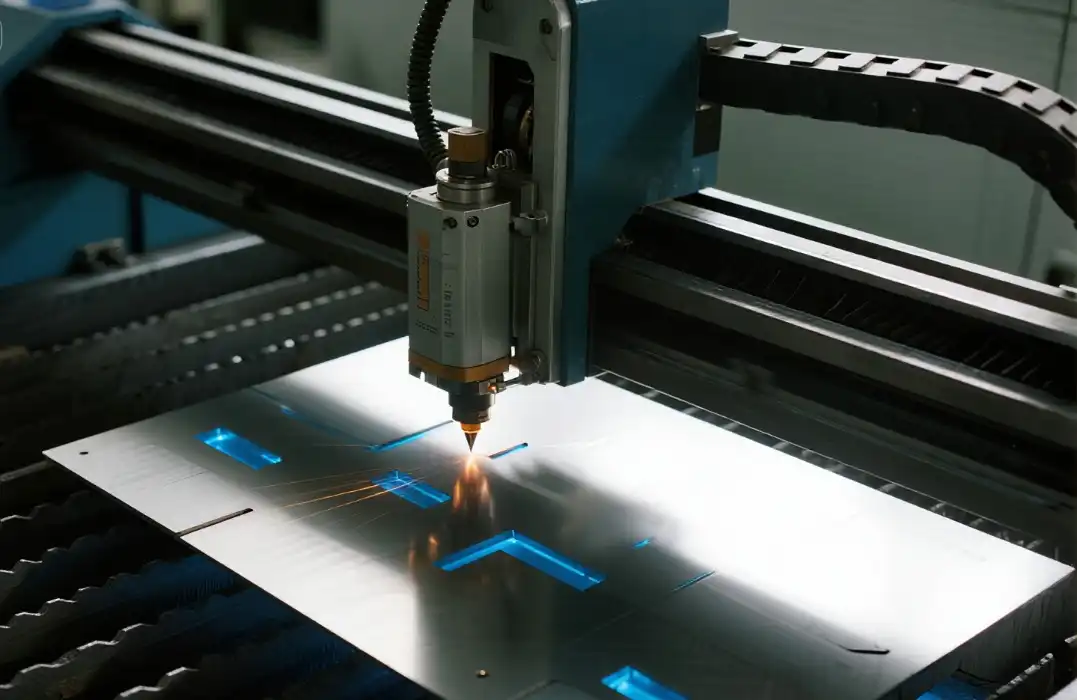

Advancements in Laser Engraving Systems

Modern laser engraving systems incorporate sophisticated software and hardware components. Computer-aided design (CAD) software allows for precise control over engraving patterns and depths. Additionally, advanced motion control systems ensure smooth and accurate movement of the laser head or workpiece. These technological advancements have significantly expanded the capabilities of laser engraving in metal fabrication.

Applications of Laser Engraving in Various Industries

Automotive and Aerospace Components

In the automotive and aerospace sectors, laser engraving plays a crucial role in part identification and traceability. Engine components, chassis parts, and avionics equipment often require permanent markings for serial numbers, barcodes, or QR codes. The durability and precision of laser-engraved markings make them ideal for these demanding applications. At BOEN Prototype, we've worked on numerous projects for automotive and aerospace clients, delivering components with crisp, long-lasting engravings that withstand harsh operating conditions.

Medical Device Manufacturing

The medical industry relies heavily on laser engraving and laser cutting for instrument marking and device serialization. Surgical tools, implants, and diagnostic equipment often require detailed engravings for regulatory compliance and patient safety. Laser engraving offers the advantage of creating sterile, biocompatible markings that don't compromise the integrity of medical devices. Our experience in medical device prototyping allows us to create precise engravings that meet stringent industry standards.

Consumer Electronics and Branding

In the world of consumer electronics, laser engraving is widely used for product customization and branding. From sleek smartphone casings to high-end audio equipment, laser-engraved logos and designs add a touch of sophistication to metal surfaces. The ability to create intricate patterns and textures opens up new possibilities for product designers. At BOEN Prototype, we've helped numerous clients bring their branding visions to life through custom laser engraving on metal prototypes and low-volume production runs.

Optimizing Laser Engraving Processes for Custom Metal Fabrication

Material Selection and Preparation

Choosing the right metal for laser engraving is crucial for achieving optimal results. Different metals react differently to laser energy, affecting the quality and depth of the engraving. For instance, aluminum typically requires higher laser power due to its reflective nature, while stainless steel often produces cleaner engravings at lower power settings. Surface preparation is equally important – cleaning the metal surface and applying specialized coatings can enhance engraving quality and consistency.

Fine-tuning Laser Parameters

Achieving the perfect laser cutting and laser engraving requires careful adjustment of various parameters. Laser power, pulse frequency, and scanning speed all play crucial roles in determining the final outcome. For delicate laser cutting and engravings on thin metal sheets, lower power settings and higher scanning speeds may be necessary to prevent material distortion. Conversely, deeper laser cutting and engravings on thicker metals might require multiple passes with higher power settings. At BOEN Prototype, our experienced technicians meticulously calibrate these parameters to ensure optimal results for each custom metal fabrication project.

Post-Processing Techniques

After laser engraving, various post-processing techniques can enhance the final product. These may include cleaning to remove any residue, applying protective coatings to preserve the engraving, or even secondary machining to refine edges or surfaces. In some cases, heat treatment may be necessary to relieve stress in the metal caused by the engraving process. Our comprehensive approach to custom metal fabrication ensures that each laser-engraved component meets the highest quality standards.

Conclusion

Laser cutting has become an indispensable tool in custom metal fabrication, offering unmatched precision and versatility. From automotive components to medical devices and consumer electronics, this technology continues to push the boundaries of what's possible in metal marking and decoration. At BOEN Prototype, we leverage our expertise in laser engraving to deliver high-quality, personalized metal components for a wide range of industries. By combining cutting-edge technology with skilled craftsmanship, we help our clients bring their innovative ideas to life through precision prototyping and low-volume production.

FAQs

What types of metals can be laser engraved?

Most metals can be laser engraved, including stainless steel, aluminum, brass, and titanium. Each metal requires specific laser settings for optimal results.

How deep can laser engraving go on metal surfaces?

Laser engraving depth varies depending on the metal type and laser power. Typically, depths range from 0.001" to 0.020" for most applications.

Is laser engraving permanent on metal surfaces?

Yes, laser engraving creates permanent markings on metal surfaces that are highly durable and resistant to wear and environmental factors.

Expert Custom Metal Fabrication with Laser Engraving | BOEN

At BOEN Prototype, we specialize in high-quality custom metal fabrication, leveraging advanced laser engraving technology. Our factory combines state-of-the-art equipment with skilled craftsmanship to deliver exceptional results for prototyping and low-volume production. As a leading manufacturer in the field, we offer tailored solutions for various industries. Experience the BOEN difference in precision and quality. Contact us at contact@boenrapid.com to discuss your custom metal fabrication needs.

References

1. Johnson, A. (2022). Advancements in Laser Engraving for Metal Fabrication. Journal of Manufacturing Technology, 45(3), 278-292.

2. Smith, R., & Brown, T. (2021). Optimizing Laser Parameters for Custom Metal Engraving. International Journal of Precision Engineering, 18(2), 145-159.

3. Lee, S., et al. (2023). Applications of Laser Engraving in Aerospace Component Manufacturing. Aerospace Engineering Review, 32(4), 412-428.

4. Garcia, M., & Wilson, K. (2022). Laser Engraving Techniques for Medical Device Identification. Journal of Biomedical Manufacturing, 29(1), 67-82.

5. Thompson, L. (2023). Material Science Aspects of Laser-Metal Interactions in Engraving Processes. Materials Science and Engineering International, 56(5), 601-615.

6. Chen, Y., & Davis, R. (2021). Advancements in Post-Processing Methods for Laser-Engraved Metal Components. Surface Technology Journal, 40(3), 235-250.