CNC machining aluminum for OEM components is a flexible and effective way to make things that is precise, long-lasting, and cost-effective. Different types and grades of aluminum are utilized in CNC machining, and each one has its own set of qualities that make it good for certain jobs. To help you choose the right grade for your needs, this article describes the most common aluminum alloys used in CNC machining for original equipment manufacturer (OEM) components. We'll also talk about the pros of aluminum CNC parts and the most recent improvements in machining methods.

Understanding Aluminum Alloys for CNC Machining

Overview of Aluminum Properties

A lot of CNC machines are made of aluminum because of its high strength-to-weight ratio, resistance to rust, and excellent heat conductivity. Businesses in many different industries, including as aviation, automotive, and customer equipment, can benefit greatly from it due to its numerous desirable characteristics. Aluminum combinations are categorized into arrangement based on their essential alloying components, each advertising unmistakable characteristics that cater to particular fabricating necessities.

Common Aluminum Grades for CNC Machining

Several aluminum grades are frequently used in CNC machining for OEM aluminum CNC parts. The 6000 series, particularly 6061 and 6082, are widely utilized due to their excellent machinability and good strength. The 7000 series, which includes 7075, is very strong and is extensively used in aircraft. The 5000 series, like 5052, is a popular choice for applications that need to be very resistant to corrosion. It's important to choose the perfect grade for your project because each one has its own set of features.

Factors Influencing Aluminum Grade Selection

Choosing the appropriate aluminum grade for CNC machining involves considering various factors. Some of these factors are the part's intended use, the amount of strength and durability needed, the part's weight, the amount of corrosion resistance needed, and the budget. Additionally, the complexity of the part design and the machining process itself can influence the selection of the aluminum grade.If you want your product to be perfect in every way, including performance and quality, you need to know about these things.

Advantages of Aluminum CNC Parts in OEM Manufacturing

Lightweight and High Strength

One of the primary advantages of using aluminum in CNC machining for OEM parts is its exceptional strength-to-weight ratio. Aluminum parts are significantly lighter than their steel counterparts while maintaining impressive strength. Weight lessening is an critical component of making strides fuel economy and generally execution, making this quality especially profitable for the car and flying divisions. Finished aluminum components are also easy to handle and carry due to the material's light weight.

Excellent Machinability and Surface Finish

Aluminum alloys are known for their excellent machinability, making them ideal for CNC processes. Because they can cut, drill, and shape very precisely, they are perfect for jobs that need complex designs and tight tolerances. Because the material isn't too stiff, it's easier to cut than steel and other harder metals. This could lower the cost of cutting. The better surface polish that aluminum CNC parts can attain without further processing is an added bonus that improves their beauty and functionality.

Corrosion Resistance and Thermal Properties

Many aluminum alloys used in CNC machining offer excellent corrosion resistance, making them suitable for applications exposed to harsh environments. This quality is especially useful for uses in the great outdoors or on the water. Heat sinks in electronics are only one example of how aluminum's strong thermal conductivity makes it a great material for this purpose. Aluminum CNC parts have these qualities, which help them last a long time and be reliable in many OEM uses.

Advanced Techniques in Aluminum CNC Machining

High-Speed Machining (HSM)

High-speed machining has revolutionized the production of aluminum CNC parts. This technique involves using higher spindle speeds and feed rates, resulting in faster material removal and reduced cycle times. HSM is particularly effective with aluminum due to its lower cutting forces compared to harder metals. An efficient solution for high-volume OEM item production, this strategy increases productivity, improves surface finish quality, and reduces tool wear.

Multi-Axis CNC Machining

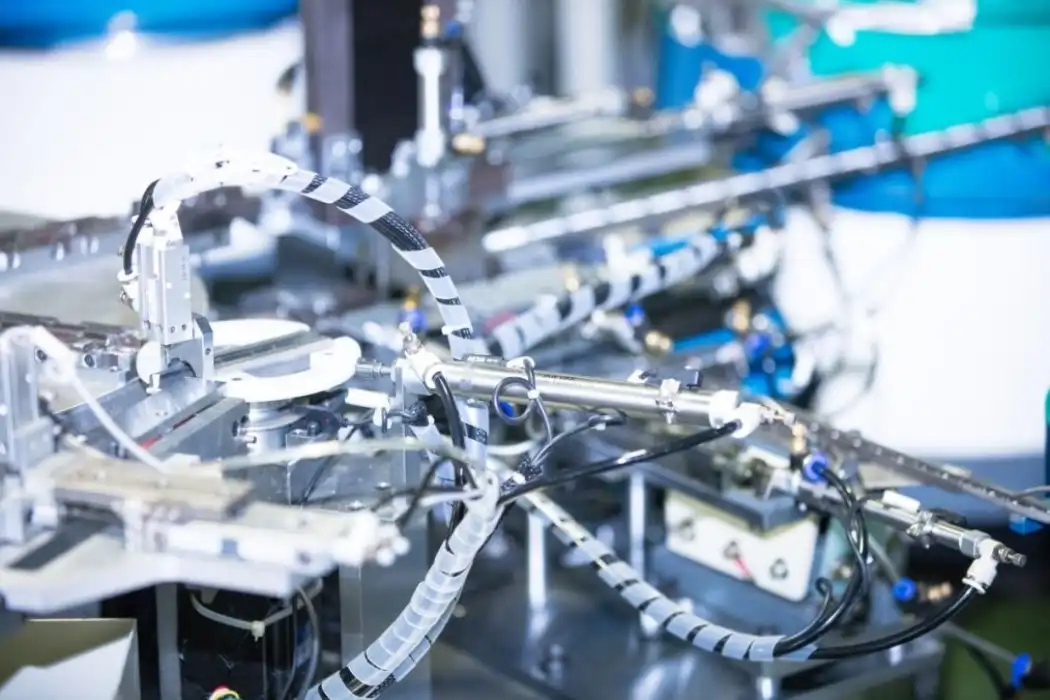

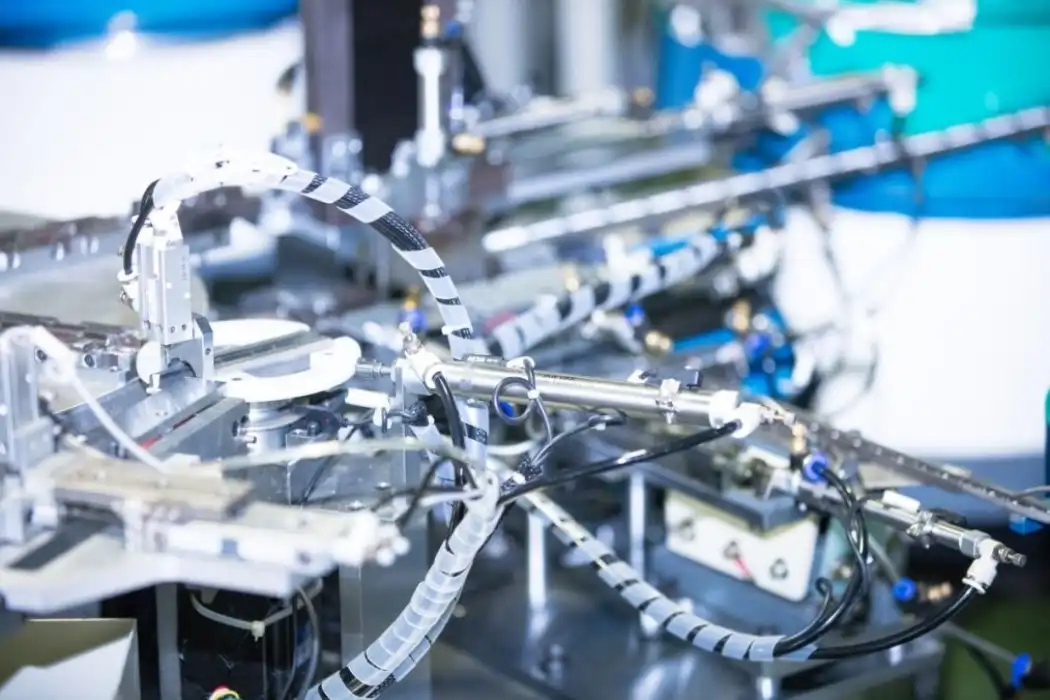

Advanced multi-axis CNC machines have significantly expanded the possibilities for aluminum part manufacturing. These machines, capable of 5-axis or even 7-axis movement, allow for complex geometries to be machined in a single setup. Components used in aeronautical and medical devices, which often have complex designs, benefit greatly from this capability. Multi-axis machining reduces the need for multiple setups, improving accuracy and reducing production time for sophisticated aluminum OEM parts.

Cryogenic Machining for Aluminum

Cryogenic machining is an imaginative method that employments greatly cold temperatures to make strides the machining handle for aluminum. By applying fluid nitrogen or other cryogenic coolants straightforwardly to the cutting zone, this strategy can essentially upgrade cutting speeds and apparatus life. For aluminum CNC parts, cryogenic machining can result in improved surface finish, reduced burr formation, and the ability to machine thinner walls and more intricate features. This method is especially important for high-precision aluminum components in businesses like aviation and restorative gadgets.

FAQ

What are the most commonly used aluminum grades for CNC machining OEM parts?

Common aluminum grades include 6061 and 6082 for general machining due to their strength and versatility, 7075 for aerospace applications needing high strength, and 5052 for parts requiring excellent corrosion resistance.

Why is aluminum a preferred material for CNC machined OEM components?

Aluminum is lightweight, strong, corrosion-resistant, and offers excellent thermal conductivity. Its high machinability also allows for complex geometries and smooth surface finishes, making it ideal for a wide range of OEM applications.

How do advanced machining techniques improve aluminum CNC parts production?

Techniques like high-speed machining, multi-axis CNC machining, and cryogenic machining enhance efficiency, precision, and surface quality. They reduce cycle time, increase tool life, and enable the production of intricate or thin-walled aluminum parts.

How do I choose the right aluminum alloy for my CNC machined part?

Selection depends on factors such as the intended use, required strength, weight constraints, corrosion exposure, and budget. Consulting with experienced manufacturers like BOEN can help match the right alloy to your performance and cost goals.

Conclusion

Many different kinds of firms can benefit from CNC machining of aluminum grades and varieties for OEM products. Components that are high-quality, precise, and inexpensive can be achieved by combining the use of modern machining techniques with careful alloy selection. Advanced CNC machining techniques for aluminum are enabling more creative and efficient manufacture of original equipment manufacturer (OEM) parts as a result of ongoing technological advancements. Optimizing production processes and delivering superior goods to suit the ever-growing needs of modern businesses is possible with a grasp of the qualities of different grades of aluminum and the use of cutting-edge machining techniques.

Certified Aluminum CNC Parts Manufacturers for OEMs | BOEN

Certified Aluminum CNC Parts Manufacturers for OEMs | BOEN At BOEN Prototype, we specialize in delivering high-quality aluminum CNC parts for OEMs across the globe.Combining our extensive understanding of aluminum alloys with our cutting-edge CNC machining capabilities, we are able to manufacture intricate components with flawless surface finishes and stringent tolerances. Our extensive list of offerings includes a wide variety of processes, from CNC machining and quick injection molding to compression molding, metal pressing, die casting, vacuum casting, and a number of 3D printing technologies, including SLA and SLS.

Throughout the whole project lifecycle, from brainstorming to manufacturing, the seasoned engineers and designers at BOEN collaborate closely with our clients to guarantee the utmost quality and accuracy. Our quick turnaround times and quality assurance position us as the perfect choice for all of your aluminum CNC parts requirements. For more information about our aluminum CNC machining services and how we can support your OEM projects, please contact us at contact@boenrapid.com.

References

Johnson, R. M. (2021). Advanced Aluminum Alloys for CNC Machining. Journal of Materials Engineering and Performance, 30(4), 2567-2580.

Smith, A. K., & Brown, T. L. (2020). Optimization of CNC Machining Parameters for Aluminum OEM Parts. International Journal of Advanced Manufacturing Technology, 106(5-6), 1845-1859.

Lee, C. H., & Park, S. Y. (2019). Cryogenic Machining of Aluminum Alloys: A Comprehensive Review. Journal of Materials Processing Technology, 268, 125-139.

Wilson, E. J. (2022). Multi-Axis CNC Machining: Advancements and Applications in Aluminum Part Production. Precision Engineering, 73, 101-115.

Garcia, M. L., & Rodriguez, F. A. (2020). High-Speed Machining Techniques for Aluminum Aerospace Components. Aerospace Science and Technology, 98, 105659.

Thompson, D. R. (2021). Selection Criteria for Aluminum Alloys in OEM CNC Machining. Materials & Design, 204, 109685.