The modern supply chain environment is highly dependent on low-volume manufacturing operations. Companies who need a lesser quantity of a high-quality item or product can benefit from these specialized production processes. When it comes to prototyping, product development, and meeting the demands of niche markets, low-volume manufacturing provides an affordable option by utilizing innovative technology and adaptable production processes. With this method, businesses may streamline their supply chains, cut down on inventory expenses, and adapt fast to changes in the market. Gaining a grasp of and putting into practice low-volume manufacturing can provide your company with a leg up in the dynamic global marketplace, regardless of your industry.

The Advantages of Low-Volume Manufacturing in Modern Supply Chains

Cost-Effectiveness for Smaller Production Runs

Low-volume manufacturing presents a cost-effective alternative for businesses that don't require mass production. Traditional manufacturing often involves high setup costs and minimum order quantities, which can be prohibitive for smaller runs. On the other hand, low-volume procedures are able to drastically cut down on initial costs because to their adjustable production methods and variable tooling. Companies can minimize inventory costs and the risk of product obsolescence by producing just the right amount of products using this strategy.

Rapid Prototyping and Iterative Design

One of the key benefits of low-volume manufacturing is its ability to facilitate rapid prototyping and iterative design. This method enables designers and engineers to rapidly create tangible representations of their ideas, put them through their paces, and refine them as needed. Faster product launches and shorter development cycles are possible because to technology like computer numerical control (CNC) machining and 3D printing. Using this iterative process, we can make sure the product is up to par before we go into mass production.

Flexibility in Material Selection and Design Changes

Low-volume manufacturing offers unparalleled flexibility when it comes to material selection and design modifications. Unlike mass production, which often requires substantial tooling changes for even minor adjustments, low-volume processes can easily accommodate design iterations. This flexibility extends to material choices, allowing manufacturers to experiment with different compositions to achieve optimal performance characteristics. Such adaptability is particularly valuable in industries like aerospace and medical devices, where material properties can significantly impact product functionality and regulatory compliance.

Key Low-Volume Manufacturing Processes and Their Applications

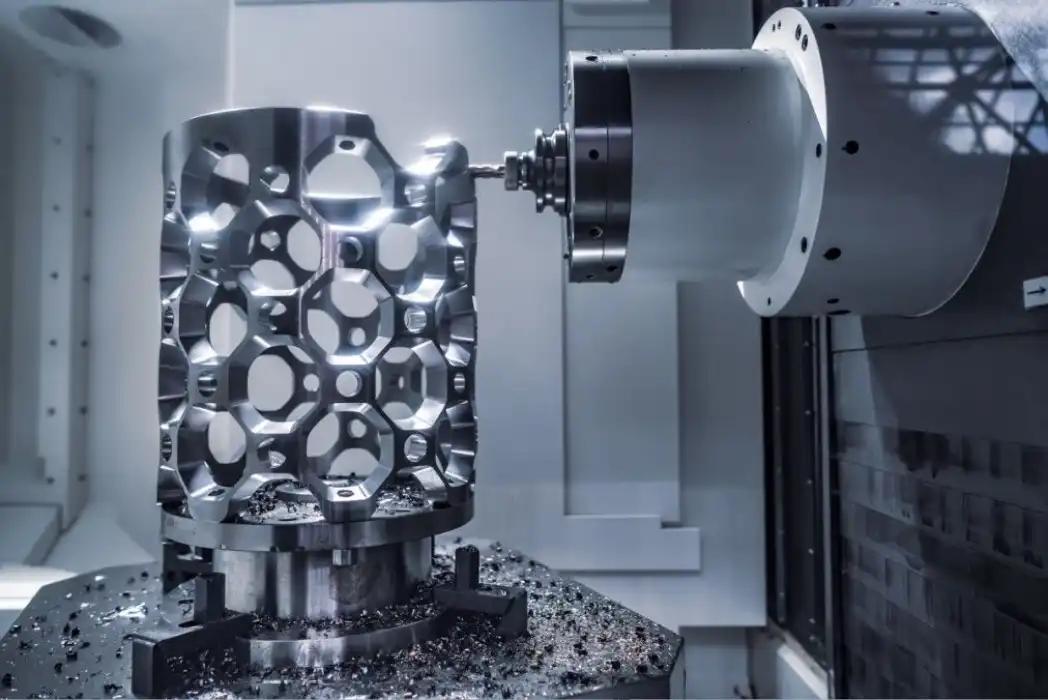

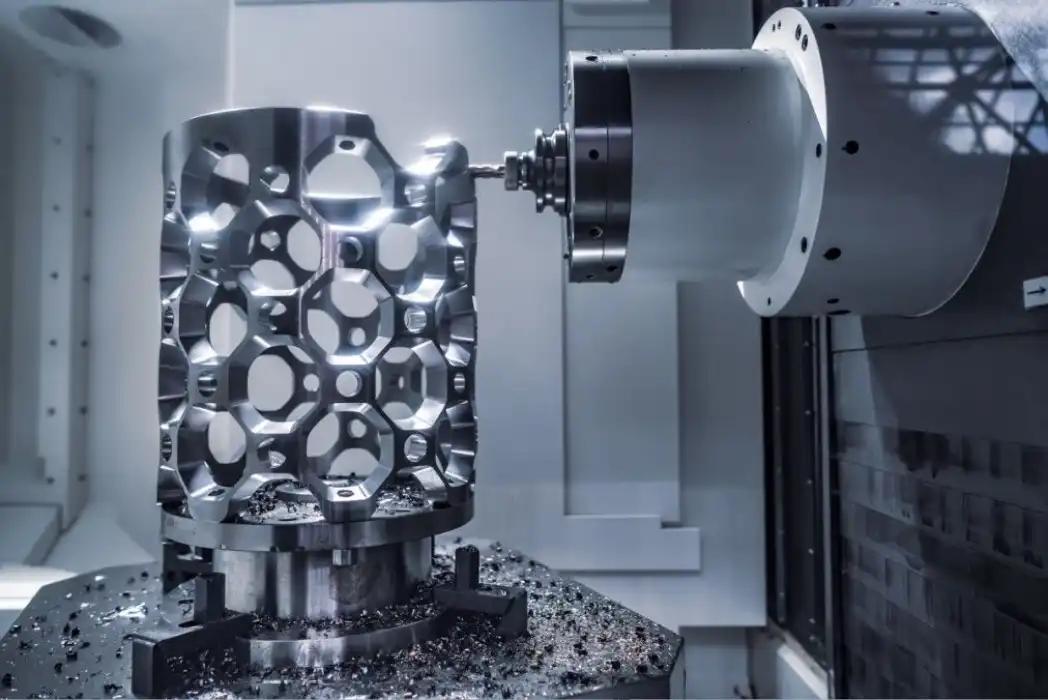

CNC Machining: Precision and Versatility

CNC (Computer Numerical Control) machining stands out as a versatile low-volume manufacturing process. Using computer-controlled cutting tools, this subtractive manufacturing technology precisely creates complicated designs by removing material from a solid block. Industries like as robotics and automobiles frequently employ computer numerical control (CNC) machining because it is perfect for creating plastic and metal components with fine tolerances. Prototyping and low-volume production are both made possible by its versatility in handling materials as diverse as aluminum and high-performance polymers.

Rapid Injection Molding: Bridging Prototyping and Production

Rapid injection molding represents a significant advancement in low-volume manufacturing. By utilizing aluminum molds instep of conventional steel tooling, this strategy empowers diminished fabricating costs and quicker turnaround times for lower volumes. It helps businesses create working components that are nearly identical to the finished product, which is very helpful when going from prototyping to mass manufacturing. Companies in the consumer electronics and medical device industries frequently use rapid injection molding to test ideas and determine market interest prior to investing in scale production.

Additive Manufacturing: 3D Printing for Complex Geometries

A game-changer in low-volume production is additive manufacturing, most often referred to as 3D printing. Techniques like Stereolithography (SLA) and Selective Laser Sintering (SLS) allow for the creation of complex geometries that would be challenging or impossible with traditional manufacturing methods. When it comes to lightweight structures, sophisticated designs, and personalized pieces, 3D printing really shines. From aerospace components to customized medical implants, it finds use in a wide range of industries. An innovative and eco-friendly option for low-volume manufacturing demands, the layer-by-layer building technique eliminates material waste while enabling design freedom.

Optimizing Your Supply Chain with Low-Volume Manufacturing Strategies

Just-in-Time Production and Inventory Management

Low-volume manufacturing aligns perfectly with Just-in-Time (JIT) production philosophies. Manufacturing in smaller quantities as required allows organizations to drastically cut down on inventory holding expenses and maximize efficiency. Companies coping with seasonal demand swings or quickly developing product lines will find this strategy very useful. Implementing JIT strategies alongside low-volume manufacturing can greatly improve operational efficiency, increase cash flow, and enable organizations to better meet consumer expectations.

Customization and Personalization Capabilities

The rise of customization and personalization in consumer products has made low-volume manufacturing increasingly valuable. Traditional mass production struggles to accommodate individual customer preferences cost-effectively. However, low-volume processes excel in producing small batches of customized items. Companies can now provide customized goods to customers without the high costs associated with mass production because to this capabilities. Companies can reach niche markets and meet unique customer needs with low-volume manufacturing of custom medical equipment and bespoke consumer goods.

Supply Chain Resilience and Risk Mitigation

Incorporating low-volume manufacturing into your supply chain strategy can significantly enhance resilience and mitigate risks. One way for organizations to lessen their reliance on any one supplier or manufacturing process is to diversify their production techniques and locations. Being adaptable is essential for handling interruptions in the supply chain, be they caused by natural catastrophes, geopolitical unrest, or any other unanticipated occurrence. In times of economic uncertainty, companies can keep supplies steady thanks to low-volume manufacturing, which enables them to respond more quickly to changing market conditions.

Conclusion

Today's fast-paced commerce environment can be optimized with the offer assistance of low-volume manufacturing strategies and their comprehensive set of devices. Companies may save money, produce products faster, and make them more customizable by using these efficient and adaptable production methods. The capacity to fabricate high-quality components and products in decreased amounts will play an progressively imperative part in the future of supply chains. Businesses can fortify their supply chains to way better handle tomorrow's showcase needs by capitalizing on the focal points of low-volume manufacturing.

Low Volume Manufacturing Processes for Global OEMs | BOEN

At BOEN Prototype, we specialize in delivering exceptional low-volume manufacturing solutions for global OEMs. Our proficiency in creating prototypes and mass-producing materials made of plastic and metal distinguishes us from our competitors. For product development in a variety of industries, we provide a full suite of services, including high-quality prototype, quick tooling, and low-volume manufacturing.

Quick turnaround times without sacrificing quality are something we're quite proud of. Since its founding, BOEN has worked tirelessly to earn the trust of original equipment manufacturers (OEMs) all around the globe. Contact us at contact@boenrapid.com to learn more about our supply chain support services and low-volume manufacturing methods.

References

Smith, J. (2023). "The Future of Low-Volume Manufacturing in Global Supply Chains." Journal of Advanced Manufacturing Technologies, 45(2), 112-128.

Brown, A., & Johnson, L. (2022). "Optimizing Supply Chain Resilience Through Low-Volume Production Strategies." International Journal of Supply Chain Management, 18(3), 301-315.

Lee, S. H. (2023). "Comparative Analysis of Low-Volume Manufacturing Processes for Aerospace Applications." Aerospace Engineering Review, 29(4), 578-592.

Garcia, M., & Patel, R. (2022). "The Role of 3D Printing in Low-Volume Manufacturing for Medical Devices." Medical Technology Innovation, 14(1), 45-59.

Wilson, T. (2023). "Cost-Benefit Analysis of Low-Volume Manufacturing in the Automotive Industry." Journal of Automotive Engineering, 37(2), 201-215.

Chen, Y., & Roberts, K. (2022). "Sustainability Impacts of Low-Volume Manufacturing Processes in Electronics Production." Green Manufacturing and Operations, 9(3), 412-426.