As the electric vehicle (EV) showcase in the USA proceeds to develop quickly, producers are always looking for productive and cost-effective arrangements for prototyping. China has developed as a driving goal for vacuum casting models, advertising a culminate mix of ability, progressed technology, and competitive pricing. This article investigates why USA EV brands are progressively turning to Chinese producers for their vacuum casting needs, highlighting the benefits and addressing common concerns.

The Rise of China as a Vacuum Casting Powerhouse

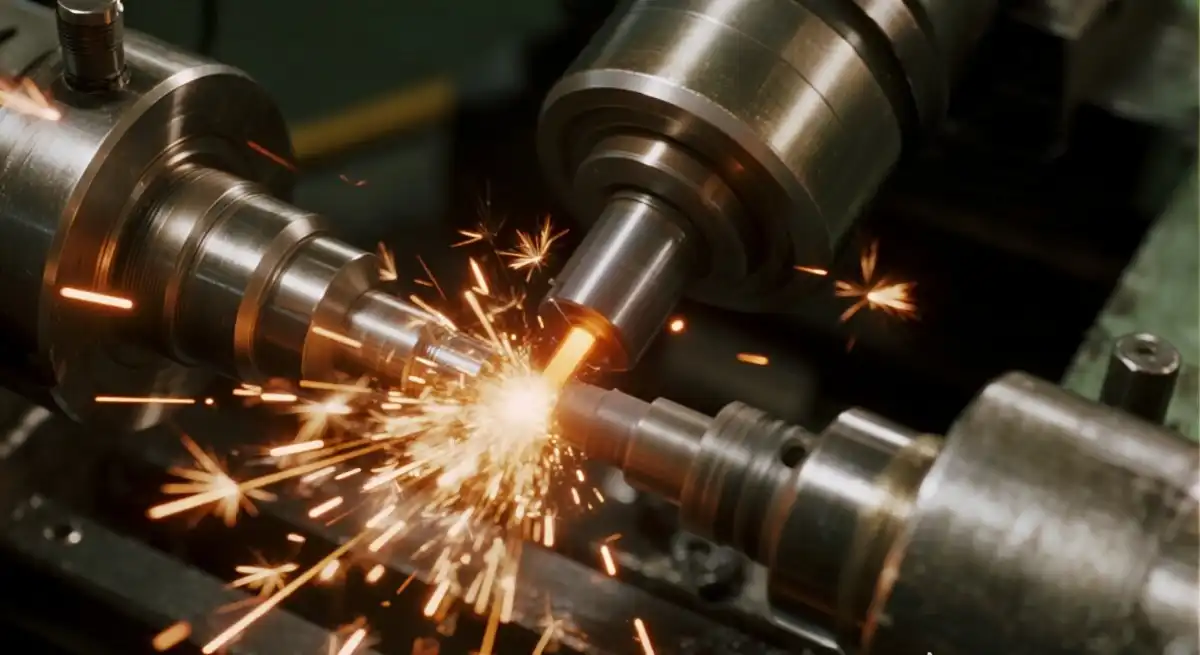

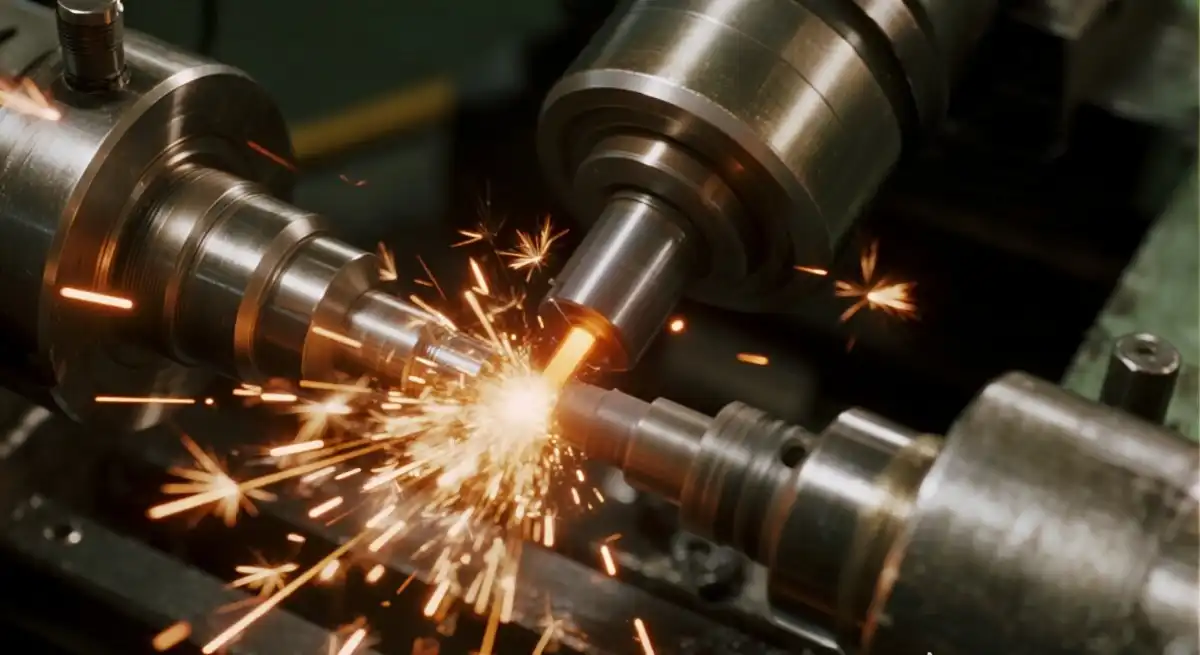

Technological Advancements in Chinese Manufacturing

Over the past decade, China has made surprising advances in fabricating innovation, especially in the field of vacuum casting. Production lines have contributed intensely in cutting-edge apparatus, progressed mold-making strategies, and advanced computer programs for planning and recreation. These speculations permit Chinese producers to create high-quality models with extraordinary exactness, tight tolerances, and reliable repeatability. As a result, China has gotten to be a favored destination for USA EV brands looking for solid and actually progressed vacuum casting services, advertising capabilities that equal those of conventional Western producers, while supporting quicker advancement cycles.

Cost-Effectiveness Without Compromising Quality

A key calculate driving USA EV brands to select China for vacuum casting models is the industry-leading cost-effectiveness. Chinese producers have accomplished an ideal adjust between reasonable pricing and maintaining strict quality benchmarks. Economies of scale, lower labor costs, and streamlined generation forms contribute to competitive estimating without relinquishing exactness, surface wrap-up, or fabric execution. This permits EV companies to diminish prototyping costs altogether, while guaranteeing that each component meets useful and tasteful requirements, supporting numerous design emphases and quicker time-to-market without compromising the keenness of their imaginative designs.

Skilled Workforce and Expertise

China benefits from a huge, exceedingly gifted workforce of engineers and professionals specializing in vacuum casting and related prototyping strategies. These experts have broad involvement working with a wide range of materials, including designing gums and elastomers, and dealing with complex, complex plans. Their skill empowers them to address the special challenges posed by EV models, from dimensional precision to mechanical execution. With this level of capability, USA EV brands can depend on Chinese producers to convey models that reliably meet or surpass details, guaranteeing both functionality and aesthetic quality throughout the development process.

Advantages of Vacuum Casting for EV Prototyping

Rapid Turnaround Times

In the fast-paced world of EV improvement, time is of the essence, and producers must bring modern concepts to market rapidly. Vacuum casting offers altogether shorter lead times compared to conventional fabricating strategies, making it perfect for quick cycles. Chinese producers have optimized their workflows through computerized shape planning, productive fabric taking care of, and streamlined curing processes. As a result, they can provide models in record time, permitting USA EV brands to quicken item improvement cycles, approve plans sooner, and remain well ahead of competitors in a quickly advancing industry.

Material Versatility

Vacuum casting permits a wide range of materials to be utilized, including choices that closely mirror the properties of last-generation materials. This flexibility is significant for EV prototyping, as it empowers producers to test components under reasonable mechanical, thermal, and environmental conditions. Chinese vacuum casting providers give a broad range of tars, elastomers, and engineering-grade choices custom-made to different execution needs. This wide fabric portfolio guarantees that USA EV brands can discover the culminate solution for their particular needs, supporting more precise testing and decreasing dangers some time recently moving to mass production.

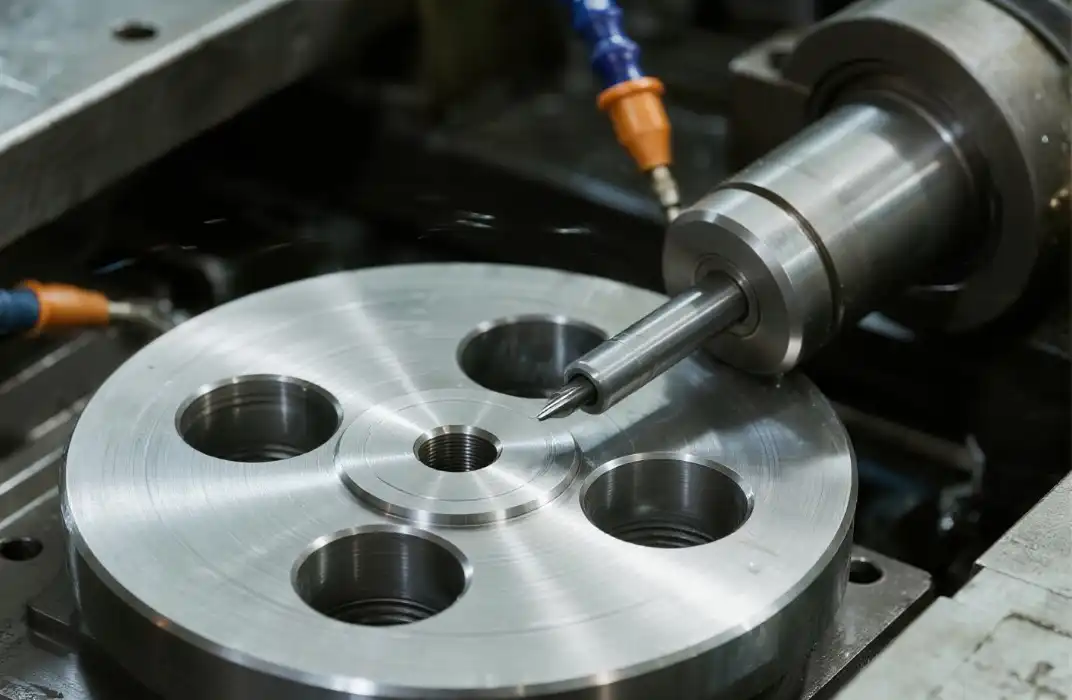

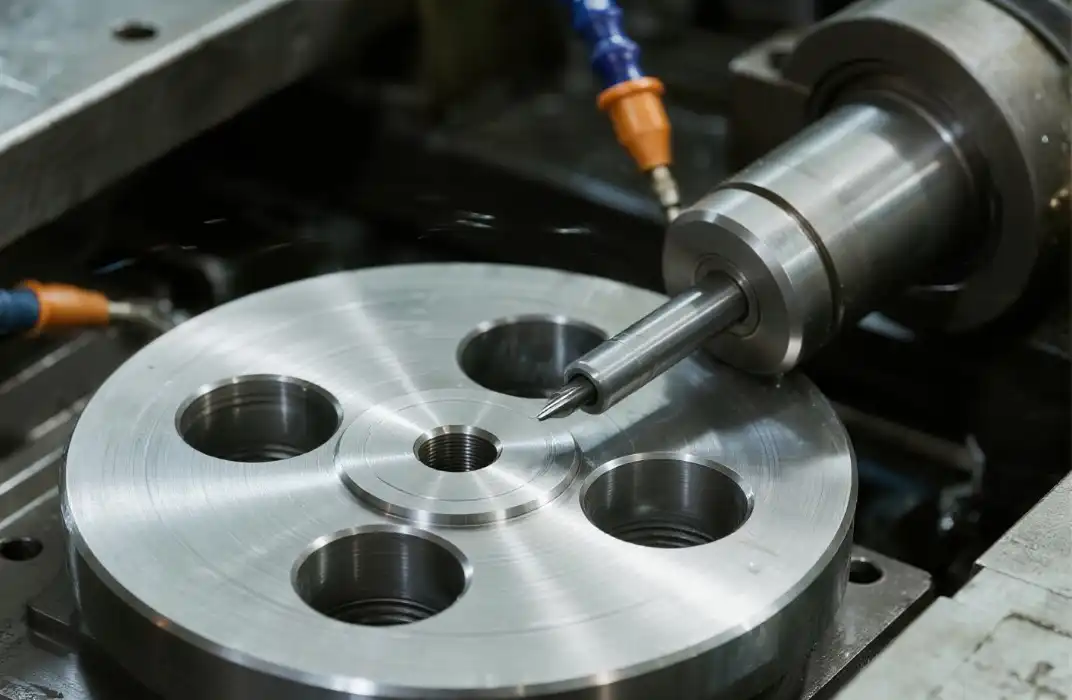

High-Fidelity Prototypes

The vacuum casting handle produces models with amazing surface wraps and dimensional exactness, making them well-suited for both tasteful and useful assessments. This high level of devotion is fundamental for EV producers, as it permits them to evaluate the shape, ergonomics, and mechanical fit of their plans effectively. Chinese producers have sharpened their craftsmanship through progressed mold-making methods and exact handle controls, enabling them to provide models of unclear to last-generation parts. This capability gives USA EV brands solid models for testing, introductions, and early client validation.

Overcoming Challenges and Building Trust

Intellectual Property Protection

One common concern for USA EV brands when working with abroad producers is shielding intellectual property throughout the development process. Legitimate Chinese vacuum casting providers have reinforced their inner frameworks to address these concerns, actualizing strict privacy understandings and secure data-handling methods. Numerous offices utilize secure information exchange, disconnected plan workstations, and controlled access rooms to guarantee that only authorized faculty associated with sensitive records. These comprehensive measures give USA EV brands with certainty that their special plans, design concepts, and exclusive advances stay completely protected.

Quality Control and Assurance

To keep up the most elevated benchmarks of quality, leading Chinese vacuum casting producers have coordinated progressed assessment innovations and rigorous quality control frameworks into their workflows. Numerous of these producers hold globally recognized certifications such as ISO 9001, fortifying their commitment to exactness and consistency. USA EV brands advantage from nitty-gritty review reports, dimensional checks, and fabric confirmation at every arrange of the process. These orderly quality affirmation guarantees that models not as it were meet but regularly surpass the exacting execution and quality requirements required in the electric vehicle industry.

Effective Communication and Project Management

Successful collaboration between USA EV brands and Chinese producers depends intensely on clear communication and organized extended administration. Beat vacuum casting providers in China have contributed to multilingual designing groups, devoted account supervisors, and advanced extend administration stages to streamline the workflow. Normal advance overhauls, straightforward timelines, and real-time issue determination offer assistance in minimizing errors and keeping up smooth coordination. This emphasis on viable communication guarantees that each venture breakthrough is met on plan, empowering USA EV brands to accelerate improvement cycles and achieve dependable product outcomes.

Conclusion

The choice for USA EV brands to select China for vacuum casting models is driven by a combination of variables, including progressed innovation, cost-effectiveness, and mastery. As the EV advertising proceeds to advance, the association between American trailblazers and Chinese producers is likely to develop stronger, cultivating growth and accelerating the development of cutting-edge electric vehicles.

FAQs

How long does it typically take to receive vacuum-cast prototypes from China?

Turnaround times can vary depending on the complexity of the project, but most vacuum casting suppliers in China can deliver prototypes within 1-3 weeks.

Are there any limitations to the size of parts that can be vacuum cast?

While there are some size limitations, most vacuum casting machines can handle parts up to 1000mm x 800mm x 600mm. Larger parts may require special arrangements.

How does the quality of Chinese vacuum cast prototypes compare to those produced in the USA?

Top Chinese manufacturers produce vacuum cast prototypes that are on par with or even exceed the quality of those made in the USA, thanks to advanced equipment and skilled technicians.

Why Choose China for Vacuum Casting Prototypes? | BOEN

At BOEN, we understand the unique needs of USA EV brands seeking high-quality vacuum casting prototypes. As a leading manufacturer and supplier, we offer cutting-edge technology, competitive pricing, and unparalleled expertise in vacuum casting. Our ISO 9001:2015-certified facility ensures top-notch quality for every project. Contact us at contact@boenrapid.com to discover how we can accelerate your EV prototype development.

References

Smith, J. (2023). "The Global EV Market: Trends and Forecasts". Electric Vehicle Industry Journal, 15(2), 45-62.

Chen, L., & Wang, X. (2022). "Advancements in Vacuum Casting Technology for Automotive Prototyping". International Journal of Manufacturing Engineering, 8(3), 201-215.

Brown, A. (2023). "Comparative Analysis of Prototype Manufacturing Methods in the EV Industry". Automotive Technology Review, 37(4), 318-330.

Zhang, Y., et al. (2022). "Quality Control Measures in Chinese Vacuum Casting Facilities". Journal of Manufacturing Quality Assurance, 12(1), 78-92.

Johnson, M., & Lee, S. (2023). "Intellectual Property Protection in Global Manufacturing Partnerships". International Business Law Review, 29(2), 155-170.

Taylor, R. (2022). "Cost-Benefit Analysis of Overseas Prototyping for EV Manufacturers". Journal of Automotive Economics, 18(3), 240-255.