Stereolithography (SLA): Precision in Liquid Resin

The SLA Process: From Liquid to Solid

Often written as SLA, stereolithography is a cutting edge rapid prototyping method that turns liquid photopolymer resin into solid things. This light-sensitive glue is put into a vat to start the process. A powerful ultraviolet laser beam then traces the cross-section of the 3D model onto the surface of the liquid. This exposure causes the resin to harden instantly, forming a thin layer of the object. The build platform then lowers slightly, allowing a new layer of liquid resin to flow over the solidified part. This process repeats, building the object layer by layer until completion.

Advantages of SLA in Product Development

Many industries choose SLA because of its many advantages. Its superior surface quality and detail resolution are its main selling points. Visual models, patterns for injection molding, and even jewelry prototypes can all benefit from SLA's ability to create parts with complex features and flawless surfaces. Tolerances as small as 0.05mm are frequently achieved using SLA, demonstrating its unsurpassed accuracy. Industries that rely on precise measurements, such as medical device manufacture, find this level of accuracy indispensable. One of the many materials that SLA is compatible with is clear resin, which allows for the ideal prototyping of see-through components or the visualization of internal structures.

Applications and Industries Leveraging SLA

SLA is used in many areas because it can be used in different ways. SLA is used in the car industry to make scale models with lots of details and working prototypes of interior parts. The aerospace sector utilizes SLA for producing complex, lightweight parts that require high accuracy.

The medical profession relies heavily on SLA for the creation of anatomical models for the purpose of surgical planning and the creation of one-of-a-kind prosthesis. The technology is also used in consumer electronics, making it possible to make quick prototypes of smooth, comfortable designs. SLA can be used for many things, and one of them is making complicated props and figures for the amusement business.

Selective Laser Sintering (SLS): Powering Complex Geometries

The SLS Method: Fusing Powders into Parts

Selective Laser Sintering, or SLS, is a powder-based rapid prototyping technology that creates robust, complex parts without the need for support structures. The process begins with a bed of fine powder material, typically nylon or polyamide. A high-power laser then selectively sinters (fuses) the powder particles together, tracing the cross-section of the 3D model. After each layer is completed, the build platform lowers, and a new layer of powder is spread over the surface. This cycle continues until the entire object is formed. The powder that hasn't been heated up supports features that hang over, which lets you make complicated shapes that might be hard to make any other way.

Strengths of SLS in Manufacturing

There are several benefits to SLS that make it a better choice for some uses. It's great that it doesn't need back structures to make parts with complicated shapes. With this work, originators can be more flexible and post-processing can be done faster. Additionally, SLS parts have great material properties that are often the same as those of injection-molded parts. The tech can be used with elastomers, metal chips, and different kinds of nylon in more complex systems. Another benefit is that SLS machines are very productive. They can nest several parts together in a single build, which makes it a cheap way to make small to medium-sized batches.

SLS Applications Across Industries

Because SLS parts are strong, they are used in many different industries. SLS is used in the auto business to make working models of engine parts and parts for the inside of cars. Aerospace manufacturers leverage SLS for producing lightweight, complex structures that would be difficult to make with traditional methods. Customizing sports gear like shoes and safety gear so that each person fits perfectly is a big use for the technology. In medicine, SLS is used to make unique prosthetics and orthotics. SLS is also being used by the fashion industry to make jewelry and accessories with unique, complicated patterns that go beyond what is normally possible in manufacturing.

Fused Deposition Modeling (FDM): Accessible and Versatile

FDM Technology: Building Layer by Layer

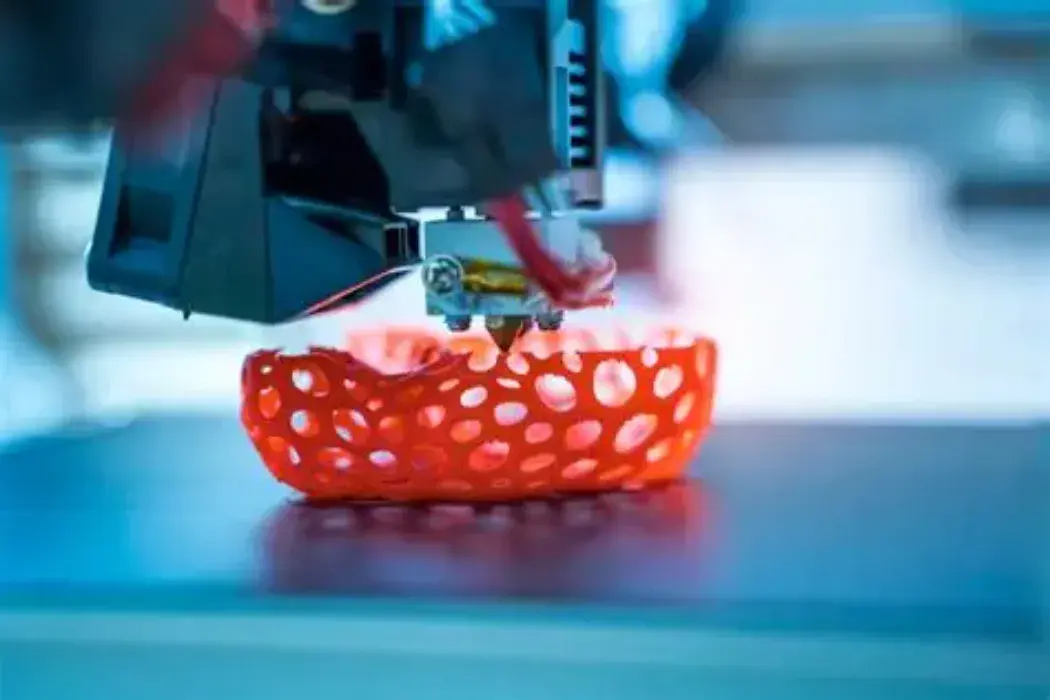

Fused Deposition Modeling, commonly known as FDM, is perhaps the most widely recognized rapid prototyping method due to its accessibility and straightforward process. FDM works by extruding thermoplastic filaments through a heated nozzle. The nozzle moves in the X and Y axes, depositing molten material onto a build platform according to the 3D model's cross-section. As each layer is completed, the build platform lowers, allowing for the next layer to be deposited. This process is carried out until the whole thing takes shape. Two kinds of material are commonly used by FDM machines: one for the main part and another for the removable support structures.

Benefits of FDM in Rapid Prototyping

The fact that FDM has many benefits has helped it become widely used. One of its best features is that it is cost-effective, both in terms of the machine and the materials. Because it is easy to use, FDM is a popular choice for small businesses, schools, and even people at home. FDM is also known for being able to work with a lot of different types of thermoplastics, each with its own set of qualities. These materials include ABS, PLA, nylon, and even specialized filaments infused with wood or metal particles. Manufacturing working prototypes rapidly is another major perk. It is generally possible to test FDM parts right after printing, which allows for quick design iterations.

FDM's Role in Various Industries

Many different areas have started using FDM because it is flexible and easy to get. FDM is often used for concept models and working prototypes in the creation and development of products. FDM is used in the car industry to make custom jigs and fixtures and to make prototypes of interior parts. FDM is used in flight to make lightweight, non-critical parts for the inside of airplanes. A subset of the medical community makes use of this technology to create 3D representations of patients' bodies for use in surgical planning and educational purposes. For the purpose of making extremely accurate scale models of buildings and city planning, FDM is widely used in the design sector. One way that FDM helps the theater business is by making stage sets, props, costumes, and other things.