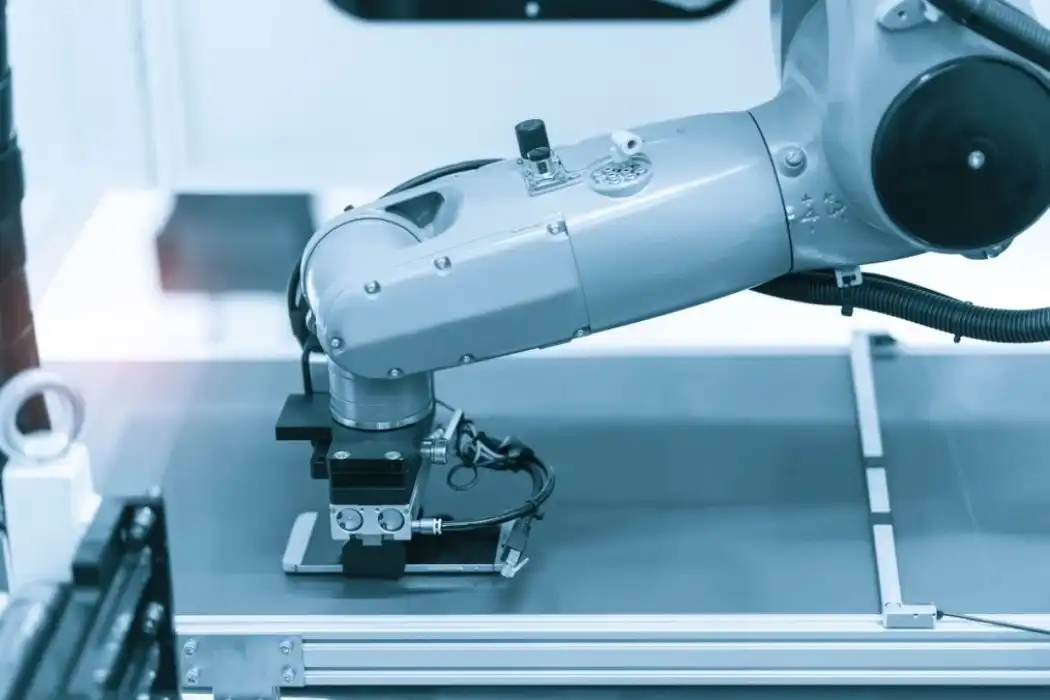

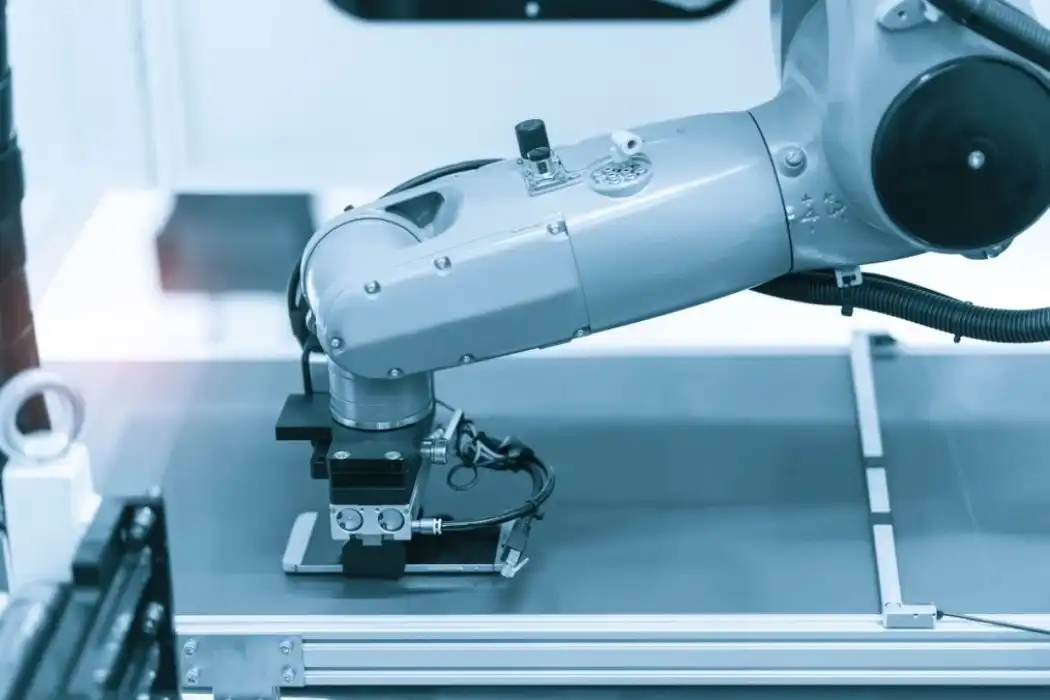

The aviation segment has experienced a change since to computer numerical control (CNC) machining, which is imperative to the fabricating of high-precision parts required for spaceships and airplanes. This cutting-edge creation get ready ensures that complex parts are made with unmatched exactness, steadfast quality, and consistency. By utilizing computer-controlled development, flying engineers can build complicated components that meet the industry's unbending criteria, expanding from lightweight fundamental pieces to fundamental engine parts. Since its integration into aviation designing has progressed flying machine execution and security whereas too expanding fabricating proficiency, CNC machining has gotten to be a significant innovation in present day flying and space investigation.

Advancements in Aerospace Manufacturing Through CNC Technology

Precision and Complexity in Component Production

CNC machining has dramatically improved the precision and complexity achievable in aerospace component production. Tolerances as tight as ±0.0001 inches can be produced by modern CNC machines, which is essential for the exacting aerospace industry. Complex geometries and delicate features that would be impossible to accomplish with conventional manufacturing techniques can now be manufactured thanks to this precision.

For instance, turbine blades used in jet engines require extremely precise airfoil shapes to maximize efficiency. These edges may be created with exact surface wraps up and ebbs and flows much obliged to CNC machining, which ensures top execution indeed in the most antagonistic circumstances. Similarly, fuel injection nozzles, which demand microscopic precision, can be manufactured with consistent quality using CNC technology.

Material Versatility and Optimization

Lightweight aluminum alloys and heat-resistant superalloys are only two of the many materials used in the aerospace sector. With the ability to modify cutting speeds, feed rates, and tooling to optimize the machining process for each unique material, CNC machining excels at working with this wide range of materials.

For example, titanium alloys, prized for their strength-to-weight ratio, are notoriously difficult to machine. Specialized cutting techniques can be programmed into CNC systems to work with titanium efficiently, minimizing tool wear and preserving part quality. Engineers may choose the best material for each application without sacrificing manufacturability thanks to this adaptability, which also applies to other aerospace materials like Inconel, carbon fiber composites, and high-strength steels.

Rapid Prototyping and Iterative Design

Rapid prototype and iterative design procedures are made possible by CNC machining, which is essential to the aerospace industry's success. CAD models can be swiftly converted into physical prototypes by engineers, who can then test them and adjust designs in response to the findings. The advancement of aeronautical technology depends on this faster development cycle. To get the best performance out of new aircraft components, several design iterations could be required. Prototype parts may be produced quickly with CNC machining, allowing engineers to do physical testing and make data-driven design choices. In aerospace engineering, quicker innovation cycles and more effective problem-solving have resulted from this prototyping agility.

Enhancing Safety and Reliability in Aerospace Components

Consistency in Production

In aerospace engineering, safety is crucial, and CNC machining greatly helps with this by guaranteeing production uniformity. Once a part has been programmed and optimized, CNC machines can reproduce it with exact precision, eliminating variations that could occur with manual machining processes.

For crucial parts like landing equip, water powered frameworks, and auxiliary components, this homogeneity is fundamental. By keeping up redress resistances and repeatable quality, CNC machining makes a difference to ensure that each component fulfills the strict security controls required in the flying region. The capacity to create indistinguishable parts increments an aircraft's in general unwavering quality and rearranges upkeep and substitution methods.

Non-Destructive Testing Integration

CNC machining centers can be integrated with advanced non-destructive testing (NDT) equipment, allowing for real-time quality control during the manufacturing process. Instead of depending just on post-production inspections, this integration makes it possible to identify flaws or irregularities in parts as they are being manufactured.

For instance, ultrasonic testing can be incorporated into the CNC machining process to check for internal flaws in critical components like turbine disks or wing spars. The safety and dependability of aircraft systems are further improved by this instant feedback loop, which guarantees that only components that satisfy the highest quality standards are assembled.

Traceability and Quality Assurance

Modern CNC machines are equipped with sophisticated monitoring systems that record detailed data about each part produced. In the aerospace sector, where quality control and regulatory compliance depend on being able to trace the manufacturing history of each component, this traceability is important.

Engineers can utilize the manufacturing data to examine the production process, pinpoint possible causes, and put remedial measures in place in the event of a part failure or performance problem. Furthermore, this degree of traceability encourages endeavors for nonstop enhancement by empowering producers to upgrade their strategies utilizing careful execution information.

Future Trends: CNC Machining in Next-Generation Aerospace Technologies

Integration with Additive Manufacturing

The future of aerospace manufacturing lies in the synergy between CNC machining and additive manufacturing (3D printing). By melding the geometric adaptability of added substance procedures with the precision of CNC machining, this crossover approach makes modern openings for component plan and fabricating.

For example, complex internal cooling channels in turbine blades can be created through additive manufacturing, while the exterior surfaces are finished to precise tolerances using CNC machining. This integration permits for the creation of parts with already outlandish geometries, possibly driving to critical changes in flying machine execution and proficiency.

Smart Manufacturing and Industry 4.0

The aerospace industry is at the forefront of adopting Industry 4.0 principles, and CNC machining is evolving to meet these new demands. Smart CNC machines equipped with sensors and connected to the Industrial Internet of Things (IIoT) can provide real-time data on machine performance, tool wear, and part quality.

Predictive maintenance is made possible by this connectivity, which lowers downtime and increases the overall efficiency of the equipment. Further improving productivity and part quality in aerospace manufacturing, machine learning algorithms can automatically improve cutting parameters by analyzing production data.

Sustainable Machining Practices

As the aerospace industry focuses on sustainability, CNC machining is adapting to meet these environmental goals. Cutting-edge CNC technologies are being developed to use environmentally friendly cutting fluids, limit material waste, and consume less energy. High-speed machining methods, for example, can drastically cut cycle times and energy consumption without sacrificing product quality. Near-net-shape machining techniques also reduce waste and the environmental effect of producing aerospace components by minimizing the quantity of material removed.

Conclusion

In aviation building, CNC machining has risen as a significant innovation that makes it conceivable to deliver high-precision parts that fulfill the requesting prerequisites of the segment. The production of airplanes and spacecraft has been transformed by its capacity to produce intricate geometries, operate with a variety of materials, and guarantee constant quality. CNC machining will surely change as the aerospace industry pushes technological limits further, incorporating new technologies and embracing sustainable methods to tackle upcoming problems. The persistent advancement of CNC innovation guarantees to progress aviation systems' execution, security, and proficiency indeed assist, setting its significant position in the segment for numerous a long time to come.

Precision Aerospace Prototyping with Advanced Machines | BOEN

At BOEN Prototype, we specialize in delivering high-quality prototypes and low-volume production for the aerospace industry. We can produce intricate aircraft components with unmatched accuracy and consistency thanks to our sophisticated CNC machining skills. To make sure every part satisfies the stringent requirements of aircraft engineering, we optimize machine settings, cutting time, surface polish, and fine-tuning tolerances using cutting-edge programming software.

In expansion to CNC machining, we have mastery in a assortment of other generation procedures, counting metal squeezing, pass on casting, vacuum casting, compression molding, fast infusion molding, and other 3D printing innovations. We can select the ideal methodology for each extend due to our adaptability, which gives our clients with the most prominent comes about.

To learn more about how BOEN Prototype can support your aerospace engineering projects with our advanced CNC machining and prototyping services, please contact us at contact@boenrapid.com.

References

Johnson, A. R., & Smith, B. T. (2022). Advancements in CNC Machining for Aerospace Applications. Journal of Aerospace Engineering, 35(2), 145-160.

Thompson, C. M. (2021). Precision Manufacturing in the Aerospace Industry: The Role of CNC Technology. International Journal of Aviation and Space Technology, 18(4), 412-428.

Davis, E. L., & Wilson, R. K. (2023). Integration of CNC Machining and Additive Manufacturing in Next-Generation Aircraft Production. Aerospace Manufacturing Technology Review, 12(1), 78-95.

Chen, H., & Roberts, S. (2022). Sustainable Practices in Aerospace Component Manufacturing: A Focus on CNC Machining. Journal of Cleaner Production, 330, 129751.

Anderson, K. P., & Taylor, M. J. (2021). Quality Assurance and Traceability in Aerospace CNC Machining Processes. International Journal of Quality & Reliability Management, 38(5), 1123-1142.

Lewis, G. R., & Brown, N. S. (2023). The Impact of Industry 4.0 on CNC Machining in Aerospace Engineering. Smart and Sustainable Manufacturing Systems, 7(2), 184-201.