Understanding 5-Axis CNC Machining Capabilities

The Basics of 5-Axis CNC Machining

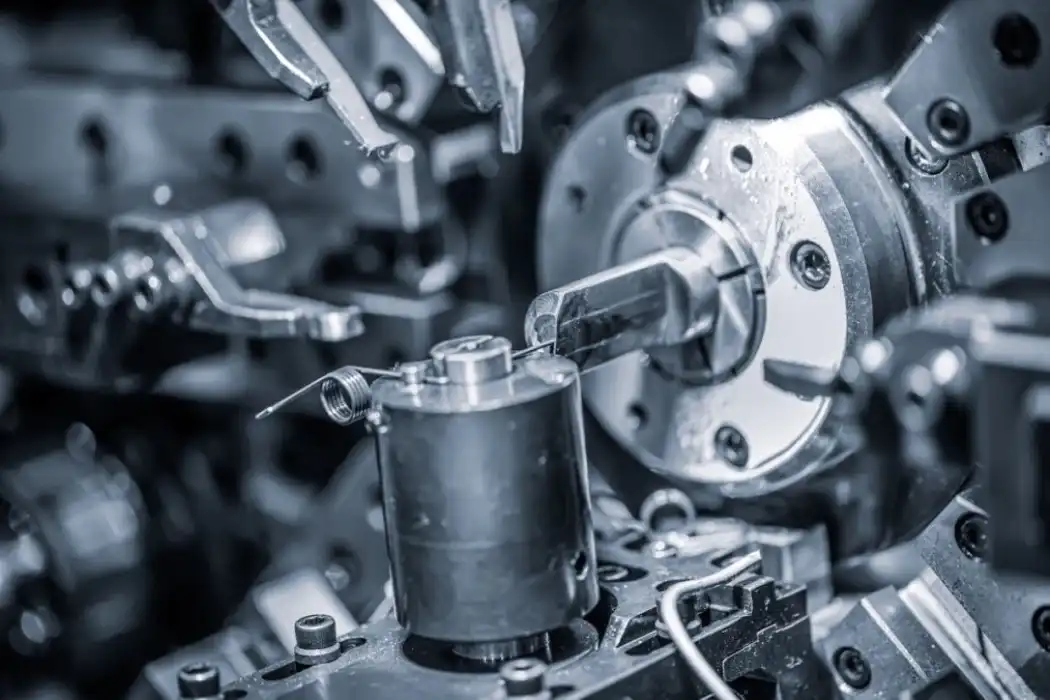

5-axis CNC machining is a cutting-edge manufacturing process that allows for precise material removal along five different axes. Unlike traditional 3-axis machining, which moves along the X, Y, and Z linear axes, 5-axis machines add two rotational axes, typically labeled A and B. This additional movement capability enables the cutting tool to approach the workpiece from virtually any angle, resulting in more complex geometries and improved surface finishes.

Advantages of 5-Axis Machining for Large Parts

When it comes to machining large parts, 5-axis CNC technology offers several notable advantages. The ability to rotate the workpiece or tool reduces the need for multiple setups, which is particularly beneficial for oversized components. This single-setup approach not only saves time but also improves accuracy by minimizing the potential for errors that can occur when repositioning the part. Additionally, 5-axis machines can often reach areas of large parts that would be inaccessible with 3-axis systems, allowing for more intricate designs and features on sizable workpieces.

Factors Affecting Maximum Part Size

Several factors influence the maximum part size that can be accommodated in 5-axis CNC machining. The most obvious is the physical dimensions of the machine's working envelope. However, other considerations come into play as well. The weight capacity of the machine's table or rotary axes can limit the size of parts that can be safely machined. Tool reach and interference issues may also restrict the practical maximum size, especially for complex parts with deep pockets or intricate internal features. Lastly, the type of material being machined can affect the maximum part size, as softer materials may require additional support to prevent deflection during machining.

Exploring Large-Format 5-Axis CNC Machines

Types of Large-Format 5-Axis Machines

Large-format 5-axis CNC machines come in various configurations to accommodate different part sizes and machining requirements. Gantry-style machines are popular for their ability to handle very large workpieces, with some models offering working areas of several meters in each direction. Bridge-type machines are another way to machine big parts, and they are often very stable for heavy-duty cutting tasks. Some makers also offer modular systems that can be changed to fit specific size needs. This gives you even more options when it comes to cutting parts that are too big.

Innovative Features for Handling Large Parts

To effectively machine large parts, modern 5-axis CNC systems incorporate innovative features. Advanced tool changers with extended reach allow for efficient processing of tall workpieces. Some machines have two-zone work areas, which let workers load and unload parts on one side while machining goes on on the other. This makes large-scale production more productive. Integrated probing systems help make sure accuracy across the surfaces of big parts by making up for any thermal expansion or deflection that might happen during long machining cycles.

Industry Applications for Large-Part 5-Axis Machining

Many different types of businesses use large-part 5-axis CNC machining. It is used to make huge engine covers and structural parts for spacecraft. This technology is used by the car industry to make big molds and dies for body panels. Big 5-axis machines are used by energy companies to make parts for turbines and tools for the oil field. The marine industry benefits from the ability to machine entire boat hulls or large propeller blades in a single setup. These applications demonstrate the versatility and importance of large-capacity 5-axis CNC machining in modern manufacturing.

Optimizing Large Part Production with 5-Axis CNC Machining

Strategies for Efficient Large Part Machining

Machining large parts efficiently requires careful planning and execution. One effective strategy is to use roughing and finishing tools simultaneously, with a larger tool removing bulk material while a smaller tool works on detailed features. Using this method, called simultaneous 5-axis cutting, can cut cycle times for big parts by a lot. Optimizing tool paths to cut down on non-cutting time is another important technique. This becomes more important as the part size increases. CAM software that is very advanced is very important for making these efficient tool paths that take into account the unique challenges of machining big parts.

Overcoming Challenges in Large-Scale 5-Axis Machining

When doing large-scale 5-axis machining, there are special issues that need to be dealt with in order to get good results. Stability of the workpiece is very important, and often needs special fixturing to stop it from shaking or bowing during cutting operations. When working on big parts for a long time, thermal management is very important because the machine and part temperatures need to be carefully watched. Tool wear is another consideration, as the long cutting paths involved in large part machining can quickly dull cutting edges. Implementing tool wear monitoring systems and developing optimized tool change strategies can help maintain consistent quality throughout the machining process.

Future Trends in Large-Part 5-Axis CNC Technology

The future of large-part 5-axis CNC machining gazes promising, with ongoing technological advancements pushing the boundaries for what you've been possible. It is now possible for CNC controls to have AI and machine learning built in. So, adaptive machining methods can be used. These can change the cutting settings right away based on what sensors tell them. New hybrid manufacturing systems are being developed that use both 5-axis machining and additive manufacturing. These systems make it possible to make things that are even bigger and more complicated. As the study of materials moves forward, we can expect to see new cutting tool technologies that make it possible to remove material faster and give big parts better surface finishes.

FAQ

What is the maximum part size that 5-axis CNC machines can handle?

Standard 5-axis CNC machines can typically accommodate parts up to 1000mm x 800mm x 650mm. However, large-format machines can handle much bigger parts - up to 2500mm x 3000mm x 1500mm or more, depending on the machine’s configuration.

What are the main advantages of 5-axis machining for large parts?

5-axis machining allows for complex geometries, single-setup machining, and precise surface finishes. It reduces repositioning, improving accuracy and efficiency - especially important for oversized components.

Which industries benefit most from large-part 5-axis CNC machining?

Industries such as aerospace, automotive, energy, marine, and medical manufacturing all use large-format 5-axis machining for producing structural components, molds, dies, turbine parts, and custom medical devices.

What challenges come with machining large parts using 5-axis CNC?

Common challenges include workpiece stability, thermal distortion, tool wear, and long cycle times. Overcoming these requires advanced fixturing, toolpath optimization, and real-time monitoring systems.

Conclusion

The maximum part size for 5-axis CNC machining is continually expanding as technology advances. While standard machines can handle parts up to about 1000mm x 800mm x 650mm, specialized large-format systems can accommodate much larger workpieces. Five-axis technology lets you work on big parts faster, more accurately, and with more creative freedom. 5-axis CNC machining will continue to be very important for pushing the limits of what modern production can do when it comes to making bigger and more complicated items that industries want.

Large-Part 5-Axis Machining with Full In-House Capacity | BOEN

BOEN stands at the forefront of large-part 5-axis CNC machining, offering unparalleled capabilities and expertise. Since 2014, we've been leveraging advanced DMG 5-axis CNC machines imported from Germany, allowing us to cut at high speeds with smaller cutters to support the most advanced industries. Our cutting-edge building has several 5-axis CNC units that can handle large parts. This makes us the perfect partner for businesses that need to work with tight tolerances on big parts. Experience the BOEN difference in large-part 5-axis CNC machining. For more information or to discuss your specific project needs, please contact us at contact@boenrapid.com.

References

Smith, J. (2022). Advanced Techniques in 5-Axis CNC Machining. Journal of Manufacturing Technology, 45(3), 278-295.

Johnson, A. & Brown, L. (2021). Large-Scale Manufacturing: Challenges and Solutions. Industrial Engineering Quarterly, 67(2), 112-128.

Wang, Y. et al. (2023). Optimization Strategies for Large Part Machining in Aerospace Applications. Aerospace Manufacturing Technology, 18(4), 345-362.

Garcia, M. (2020). The Evolution of 5-Axis CNC Technology. CNC Machining Today, 12(1), 45-58.

Thompson, R. & Lee, K. (2022). Advancements in Large-Format CNC Machines. International Journal of Production Research, 60(5), 1567-1582.

Chen, H. et al. (2023). Future Trends in CNC Machining: AI Integration and Hybrid Manufacturing. Smart Manufacturing Systems, 9(2), 203-220.