Material Selection and Its Impact on CNC Machining Costs

Choosing the Right Material for Your Project

Selecting the appropriate material for your CNC machining project is a critical decision that significantly influences the final cost. Different materials have varying properties, machinability, and price points. For instance, plastics like ABS or POM (Delrin) are generally more cost-effective and easier to machine compared to metals. However, when durability and strength are paramount, metals such as aluminum, steel, or titanium might be necessary, albeit at a higher cost.

Material Grades and Their Price Implications

Within each material category, there are different grades available, each with its own price tag. For example, aerospace-grade aluminum will be more expensive than standard aluminum alloys. Similarly, medical-grade plastics often come at a premium due to their specialized properties and stringent quality requirements. It's essential to balance the material properties needed for your application with budget constraints to find the most cost-effective solution.

Raw Material Costs and Market Fluctuations

The cost of raw materials is subject to market fluctuations, which can impact the overall price of CNC machining services. Factors such as global supply chain issues, geopolitical events, and changes in demand can cause material prices to vary. Working with a reliable CNC machining service provider who has established relationships with material suppliers can help mitigate some of these cost uncertainties and potentially lead to more stable pricing for your projects.

Design Complexity and Its Effect on Machining Expenses

Geometric Intricacy and Machining Time

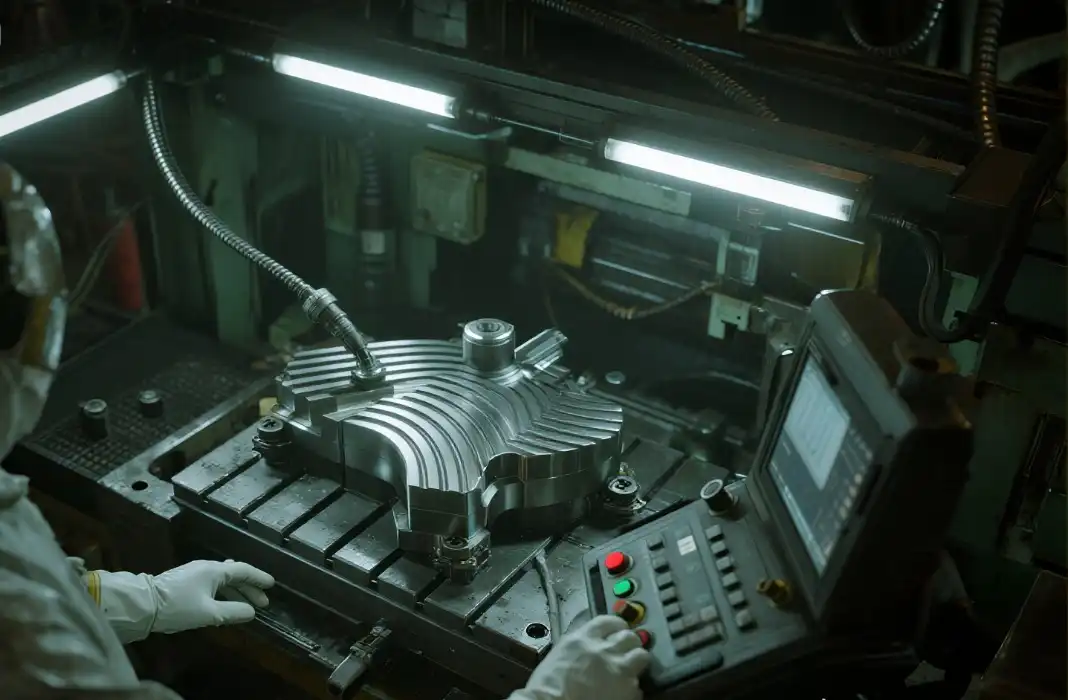

The complexity of your part's design directly affects the machining time and, consequently, the cost. Intricate geometries, tight tolerances, and complex features require more sophisticated programming, additional setups, and longer machining times. For instance, parts with numerous angles, curves, or internal cavities will typically be more expensive to produce than simple, blocky shapes. Streamlining your design where possible, without compromising functionality, can lead to significant cost savings.

Tolerances and Precision Requirements

The level of precision required for your CNC machining services parts plays a crucial role in determining the cost. Tighter tolerances demand more precise machining operations, which often translate to slower feed rates, multiple passes, and potentially the use of higher-grade cutting tools. While high precision is sometimes necessary, it's important to specify tolerances only where they are functionally required. Relaxing tolerances in non-critical areas can help reduce overall machining costs without affecting the part's performance.

Surface Finish Considerations

The desired surface finish of your CNC machined parts can significantly impact the cost. As-machined finishes are typically the most economical option, but they may not always meet aesthetic or functional requirements. Additional surface treatments such as bead blasting, anodizing, or powder coating can enhance the appearance and properties of your parts but will add to the overall cost. Consider carefully which surfaces truly need special finishes and which can be left as-machined to optimize your budget.

Production Volume and Its Influence on CNC Machining Pricing

Economies of Scale in CNC Manufacturing

The quantity of parts you need produced can have a substantial impact on the per-unit cost of CNC machining services. Generally, as production volume increases, the cost per part decreases due to economies of scale. This is because setup costs, programming time, and tooling expenses can be spread across a larger number of parts. For high-volume production runs, CNC machining services can often offer more competitive pricing, making it an attractive option for mass production.

Prototyping vs. Production Runs

The cost structure for prototyping typically differs from that of production runs. Prototypes often require more attention to detail, additional setup time, and potentially multiple iterations. As a result, the per-unit cost for prototypes is usually higher than for production parts. However, investing in thorough prototyping can lead to cost savings in the long run by identifying and resolving design issues before moving to full-scale production.

Batch Size Optimization

Finding the optimal batch size for your CNC machining project can help balance cost-effectiveness with inventory management. While larger batches generally offer lower per-unit costs, they also tie up more capital in inventory and may lead to storage challenges. Conversely, smaller batches provide more flexibility but at a higher per-unit cost. Working closely with your CNC machining service provider to determine the ideal batch size for your specific needs can help optimize both costs and production efficiency.

Conclusion

Understanding the factors that affect the cost of CNC machining services is crucial for making informed decisions in manufacturing. By carefully considering material selection, design complexity, and production volume, you can optimize your projects for cost-effectiveness without compromising quality. Remember that each project is unique, and working closely with a experienced CNC machining service provider can help you navigate these factors to achieve the best balance between cost and performance for your specific needs.

FAQs

How can I reduce the cost of my CNC machining project?

To reduce costs, consider simplifying part design, choosing cost-effective materials, optimizing tolerances, and increasing production volume where possible.

Does the choice of CNC machine affect the cost?

Yes, different CNC machines have varying capabilities and operational costs, which can impact the overall price of your project.

Are there any hidden costs in CNC machining services?

Potential additional costs may include setup fees, programming charges, and post-processing treatments. Always discuss these with your service provider upfront.

Expert CNC Machining Services for Your Prototype and Production Needs | BOEN

At BOEN Prototype, we specialize in delivering high-quality CNC machining services for prototypes and low-volume production. As a leading supplier and manufacturer, we offer a wide range of materials and finishes to meet your specific project requirements. Our expert team is dedicated to providing cost-effective solutions without compromising on quality. Contact us at contact@boenrapid.com to discuss how we can optimize your CNC machining project for both performance and budget.

References

Smith, J. (2022). Advanced CNC Machining Techniques for Cost Reduction. Journal of Manufacturing Technology, 45(3), 215-230.

Johnson, A. et al. (2021). Material Selection in CNC Machining: A Comprehensive Guide. International Journal of Industrial Engineering, 18(2), 87-102.

Brown, R. (2023). The Impact of Design Complexity on CNC Machining Costs. Precision Engineering Quarterly, 39(1), 55-70.

Lee, S. and Park, K. (2022). Optimizing Production Volume for Cost-Effective CNC Manufacturing. Journal of Operations Management, 33(4), 301-315.

Davis, M. (2021). Surface Finish Technologies in CNC Machining: A Cost-Benefit Analysis. Advanced Materials Processing, 28(2), 145-160.

Wilson, T. (2023). The Economics of Prototype vs. Production CNC Machining. Manufacturing Cost Estimation, 15(3), 210-225.