How to Select the Right CNC Machining Service for Startups?

Selecting the right CNC machining service for startups is crucial for success in product development and manufacturing. To make the best choice, consider factors such as expertise, capabilities, turnaround time, and cost-effectiveness. Look for a provider with experience in your industry, a wide range of materials and finishes, and advanced technology. Evaluate their communication and customer service, as well as their ability to handle prototypes and low-volume production. Don't forget to check their quality control measures and certifications. By carefully assessing these aspects, startups can find a CNC machining partner that supports their growth and innovation.

Understanding CNC Machining and Its Importance for Startups

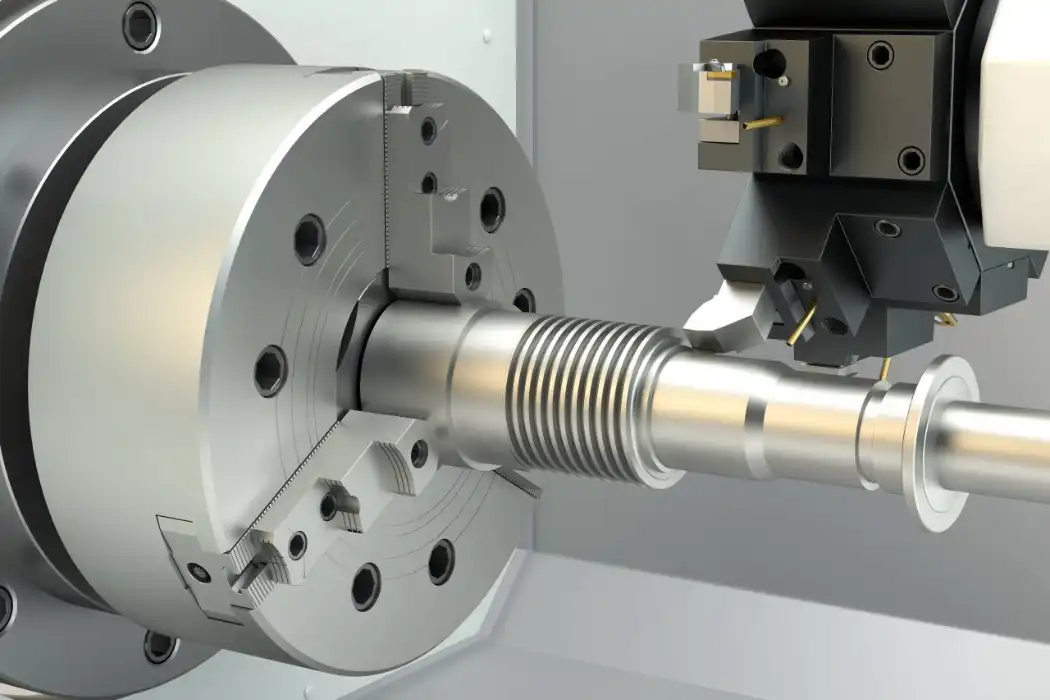

What is CNC Machining?

Computer Numerical Control (CNC) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This advanced technology allows for precise and repeatable production of complex parts and components. CNC machines can perform a variety of operations, including milling, turning, drilling, and routing, making them versatile tools for startups in various industries.

Benefits of CNC Machining for Startups

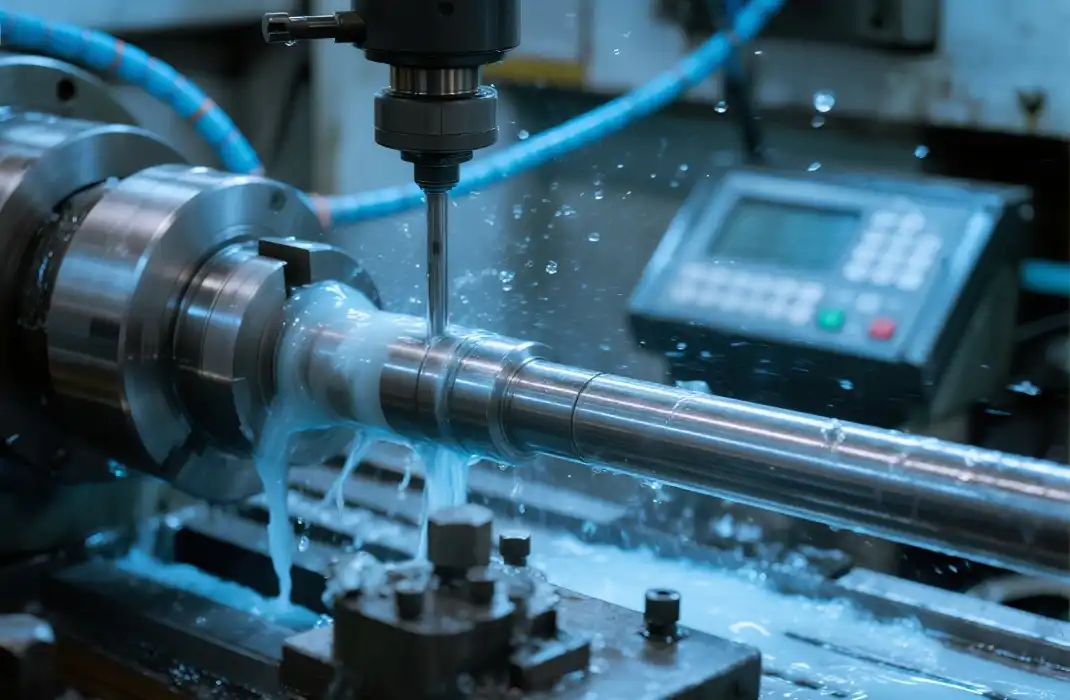

For startups, CNC machining service offers numerous advantages. It provides quick turnaround times, which is crucial for rapid prototyping and iterative design processes. The high accuracy and repeatability ensure consistent quality across production runs. CNC machining service also allows for the use of a wide range of materials, including various plastics and metals, giving startups flexibility in their product development. Additionally, it's suitable for producing both small, intricate parts and larger components, making it adaptable to different project needs.

How CNC Machining Supports Innovation

CNC machining plays a vital role in supporting innovation for startups. It enables the creation of complex geometries that might be impossible with traditional manufacturing methods. This capability allows startups to push the boundaries of product design and functionality. Moreover, the ability to quickly produce prototypes helps startups test and refine their ideas rapidly, accelerating the innovation cycle. The precision of CNC machining also ensures that final products meet exact specifications, which is crucial for startups entering competitive markets.

Key Factors to Consider When Choosing a CNC Machining Service

Expertise and Experience

When selecting a CNC machining service, it's essential to consider their expertise and experience. Look for a provider with a proven track record in your specific industry. Experienced CNC machining services will have encountered a wide range of challenges and developed innovative solutions. They can offer valuable insights into design for manufacturability, potentially saving you time and resources. Additionally, an experienced provider will be familiar with industry standards and regulations, ensuring your products meet necessary requirements.

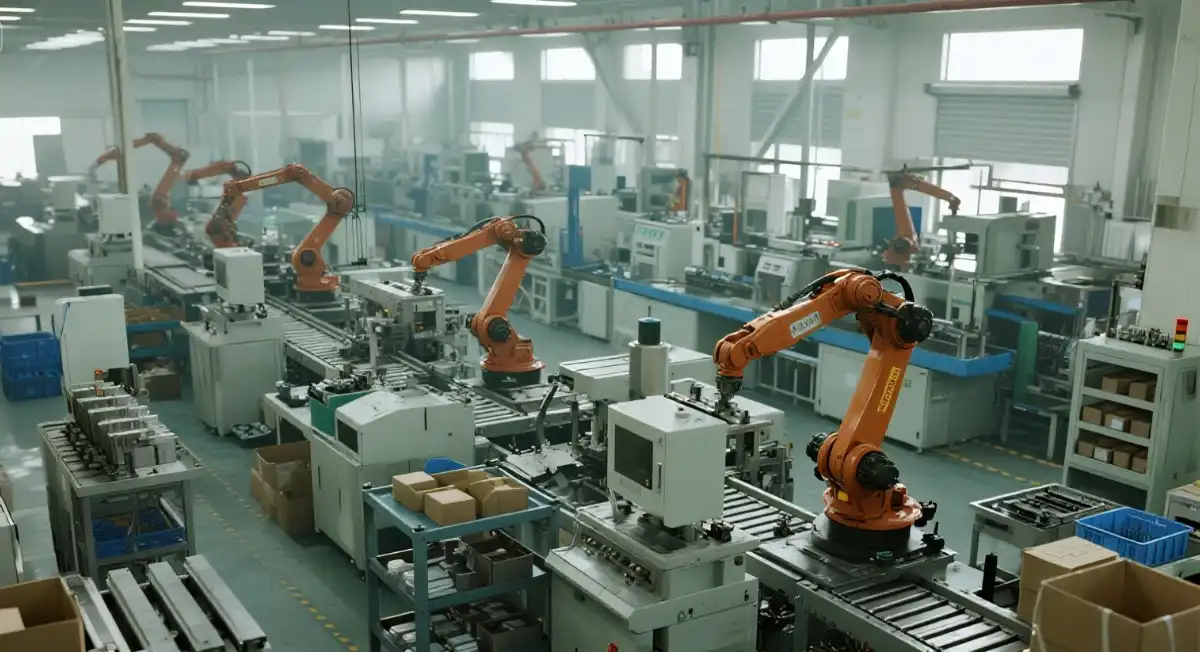

Technological Capabilities

The technological capabilities of a CNC machining service are crucial for startups. Assess the range of CNC machines they operate, including multi-axis machines that can handle complex geometries. Inquire about their CAD/CAM software capabilities, as advanced software can optimize machining processes for efficiency and precision. Also, consider whether they offer additional services like 3D printing or injection molding, which can be beneficial for comprehensive product development. A provider with cutting-edge technology can help your startup stay competitive and innovative.

Material and Finish Options

The variety of materials and finish options offered by a CNC machining service is another important factor. A good provider should work with a wide range of materials, including various plastics like ABS, POM, and PEEK, as well as metals such as aluminum, steel, and titanium. They should also offer different surface finishes, such as anodizing, powder coating, and bead blasting. This diversity allows startups to choose the best materials and finishes for their specific product requirements, whether it's for functional prototypes or final production parts.

Evaluating CNC Machining Services for Startup Needs

Quality Control and Certifications

Quality control is paramount when choosing a CNC machining service. Look for providers with robust quality management systems and relevant industry certifications. ISO 9001 certification, for instance, indicates a commitment to quality management principles. Ask about their inspection processes and tolerances. A reputable CNC machining service should use advanced measurement tools and provide detailed inspection reports. For startups in specialized industries like medical devices or aerospace, additional certifications may be necessary. Ensuring your chosen provider meets these quality standards will help guarantee the reliability and performance of your products.

Turnaround Time and Scalability

For startups, speed to market is often critical. Evaluate the turnaround times offered by potential CNC machining services. Look for providers who can deliver quick prototypes without compromising on quality. Additionally, consider their capacity to scale production as your startup grows. A good CNC machining partner should be able to handle both small prototype runs and larger production volumes efficiently. Discuss their production planning processes and how they manage rush orders. The ability to adapt to your changing needs can be a significant advantage as your startup evolves.

Cost-Effectiveness and Pricing Structure

While cost shouldn't be the only factor, it's undoubtedly important for startups with limited budgets. Compare pricing structures among different CNC machining services, but be wary of choosing solely based on the lowest price. Consider the total value offered, including quality, turnaround time, and additional services. Some providers may offer volume discounts or favorable terms for startups. Look for transparency in pricing and ask for detailed quotes that break down costs. A cost-effective CNC machining service should help you optimize your designs for manufacturability, potentially reducing overall production costs in the long run.

Conclusion

Selecting the right CNC machining service is a crucial decision for startups looking to bring their innovative ideas to life. By carefully evaluating factors such as expertise, technological capabilities, material options, quality control, turnaround time, and cost-effectiveness, you can find a partner that aligns with your startup's needs and growth trajectory. Remember, the ideal CNC machining service should not just be a supplier, but a collaborative partner in your product development journey. With the right choice, you can leverage the precision, versatility, and efficiency of CNC machining to accelerate your startup's success in the competitive market.

FAQs

What materials can be used in CNC machining?

CNC machining can work with a wide range of materials, including various plastics like ABS, PP, PMMA, and metals such as stainless steel, aluminum, and brass. The choice depends on your specific product requirements.

How long does CNC machining typically take?

Turnaround times can vary depending on the complexity of the part and the service provider. However, CNC machining generally offers quick turnaround times, often within a few days to a couple of weeks for prototypes.

Is CNC machining suitable for both prototypes and production runs?

Yes, CNC machining is versatile and can be used for both prototyping and low to medium volume production runs, making it an excellent choice for startups at various stages of product development.

Expert CNC Machining Services for Startups | BOEN

At BOEN Prototype, we specialize in providing top-tier CNC machining services tailored for startups. Our state-of-the-art facilities and experienced team ensure high-quality prototypes and low-volume production across various industries. We offer a wide range of materials, finishes, and quick turnaround times to support your innovation journey. As your trusted manufacturing partner, we're committed to helping your startup succeed. Contact us at contact@boenrapid.com to discuss your CNC machining needs and how we can bring your ideas to life.

References

Smith, J. (2023). "CNC Machining for Startups: A Comprehensive Guide". Journal of Manufacturing Technology.

Johnson, A. et al. (2022). "Selecting the Right Manufacturing Partner for Your Startup". Entrepreneurship Today.

Brown, R. (2023). "The Impact of CNC Technology on Product Innovation". Tech Innovation Quarterly.

Lee, S. (2022). "Quality Control in CNC Machining: Best Practices for Startups". Quality Engineering Review.

Wilson, M. (2023). "Cost-Effective Manufacturing Strategies for Tech Startups". Startup Business Journal.

Taylor, K. (2022). "Materials Science in CNC Machining: Expanding Possibilities for Product Design". Advanced Materials Today.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.