Where Can I Get Prototypes Made Quickly? A Complete Guide

Getting prototypes made fast requires finding the right manufacturing partner who combines advanced technology with efficient processes. Professional prototyping services offer various rapid manufacturing methods including CNC machining, 3D printing, and quick-turn injection molding, typically delivering parts within 1-7 days. The key lies in selecting a provider with the right equipment, materials in stock, and streamlined workflows that can transform your designs into physical parts without compromising quality or accuracy.

Understanding Different Rapid Prototyping Methods and Technologies

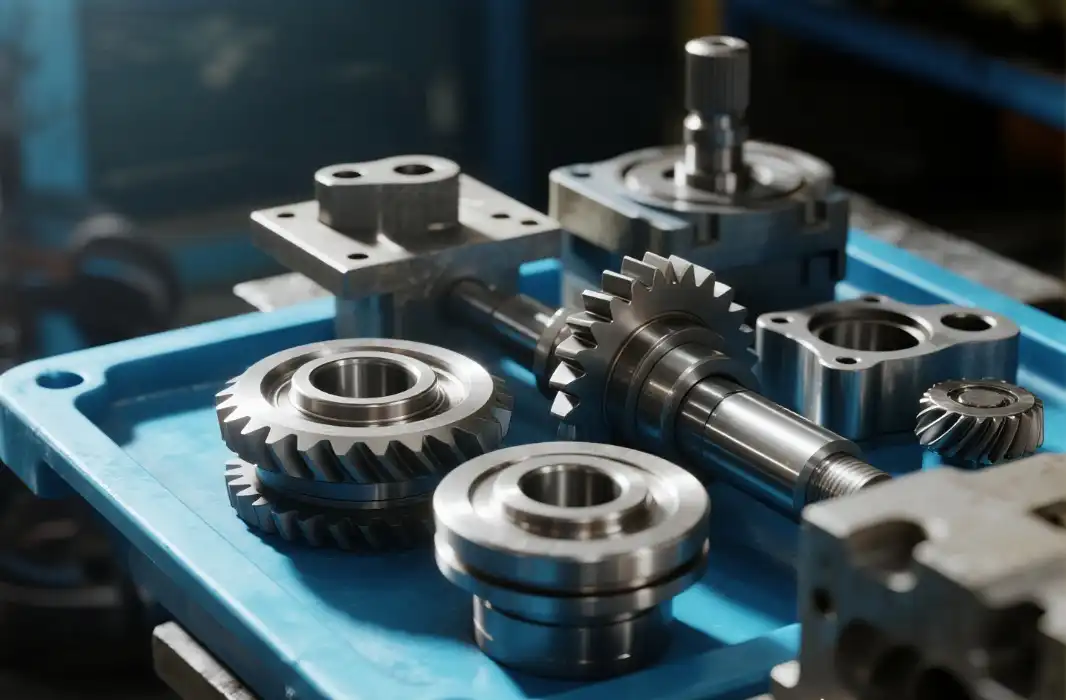

CNC Machining for Speed and Precision

CNC machining stands out as one of the most versatile methods for creating prototypes quickly from both metal and plastic materials. Modern multi-axis CNC machines can produce complex geometries with exceptional accuracy, often completing parts within 24-48 hours. This technology excels when you need prototypes that match production-grade materials and tolerances.

The speed of CNC prototyping depends largely on the complexity of your design and the material chosen. Aluminum alloys machine rapidly and provide excellent strength-to-weight ratios, making them ideal for functional testing. Engineering plastics like ABS, polycarbonate, and nylon offer quick turnaround times while maintaining dimensional stability. Advanced shops run lights-out manufacturing, allowing production to continue overnight without supervision.

Material availability plays a crucial role in CNC prototyping speed. Established prototyping facilities maintain extensive inventories of common materials, eliminating procurement delays. They also utilize high-speed cutting strategies and optimized tool paths that reduce machining time while maintaining surface quality. Some providers offer same-day service for simple parts when standard materials are selected.

3D Printing Technologies for Complex Geometries

Additive manufacturing technologies have revolutionized rapid prototyping by enabling overnight production of intricate designs for prototypes made fast. SLA (stereolithography) printing creates smooth, detailed parts perfect for visual models and form-fit testing. The process builds parts layer by layer using UV-cured resins, achieving feature resolutions as fine as 0.025mm. Most SLA parts complete within 4-12 hours depending on size and layer thickness.

SLS (selective laser sintering) offers durability advantages for functional prototypes requiring mechanical strength. This powder-based process produces parts without support structures, enabling more design freedom and faster post-processing. Nylon materials used in SLS provide excellent chemical resistance and flexibility. Build times typically range from 8-24 hours, with multiple parts produced simultaneously to maximize efficiency.

Metal 3D printing technologies like DMLS (direct metal laser sintering) bring rapid prototyping capabilities to aerospace, medical, and automotive applications. While build times are longer than plastic processes, the ability to create complex internal channels and lightweight lattice structures often eliminates assembly steps. Post-processing requirements including support removal and surface finishing should be factored into timeline estimates.

Quick-Turn Injection Molding and Casting Processes

Rapid injection molding bridges the gap between prototyping and production, delivering molded parts within days rather than weeks. Aluminum tooling reduces mold fabrication time while providing sufficient durability for prototype quantities. This approach produces parts identical to final production components, enabling thorough testing of form, fit, and function.

Vacuum casting offers another fast solution for producing small batches of prototype parts. The process creates silicone molds from master patterns, then casts polyurethane resins that simulate production plastics. Turnaround times typically range from 3-5 days including mold creation. This method excels for parts requiring specific colors, textures, or overmolded components.

Compression molding provides rapid prototyping options for rubber and composite materials. The process applies heat and pressure to form materials in metal molds, producing parts with excellent surface finish and dimensional accuracy. Setup times are minimal compared to injection molding, making it cost-effective for prototype quantities while maintaining production-representative properties.

Key Factors That Affect Prototype Production Speed

Design Complexity and Manufacturing Considerations

Part geometry significantly impacts production timelines across all prototyping methods. Simple prismatic shapes with standard features machine quickly, while complex organic forms require longer programming and production times. Undercuts, deep pockets, and thin walls add complexity that extends manufacturing duration. Designing with manufacturing in mind accelerates the entire process.

Tolerance requirements directly affect production speed and method selection. Tight tolerances demand slower cutting speeds, additional finishing operations, and thorough inspection procedures. When extreme precision isn't critical for initial prototypes, relaxing tolerances can reduce turnaround time substantially. Communicate which dimensions are critical versus reference to help manufacturers optimize production strategies.

Assembly requirements should be evaluated during design phases to minimize production time. Consolidating multiple components into single parts through advanced manufacturing techniques eliminates assembly steps. However, breaking complex designs into simpler components sometimes enables parallel production paths that reduce overall timeline. Consider both approaches when planning your prototype strategy.

Material Selection and Availability Impact

Standard materials kept in stock enable immediate production starts, while specialty alloys or custom compounds introduce procurement delays for prototypes made fast. Common aluminum grades like 6061 and 7075 are readily available at most prototyping facilities. Engineering plastics including ABS, polycarbonate, and acetal typically ship same-day from material suppliers. Exotic materials may require several days or weeks to source.

Material properties affect machining parameters and processing speeds. Free-machining alloys cut faster than hardened steels or titanium. Plastics generally machine quicker than metals but may require special handling to prevent melting or distortion. Understanding these relationships helps set realistic timeline expectations and guides material selection for urgent projects.

Certification requirements for materials add time but ensure quality and traceability. Aerospace and medical applications often mandate certified materials with complete documentation. While this extends procurement time, many prototyping services maintain certified material inventory for common specifications. Discuss certification needs early to avoid unexpected delays.

Communication and Project Management Efficiency

Clear communication accelerates every aspect of prototype production. Providing complete 3D CAD files, detailed drawings, and specifications eliminates back-and-forth clarifications. Include critical dimensions, surface finish requirements, and intended use information upfront. The more information manufacturers have initially, the faster they can begin production.

File preparation quality directly impacts production speed. Native CAD files allow manufacturers to extract dimensions and features directly, while poorly exported files may require repair or clarification. STL files for 3D printing should be checked for errors like inverted normals or non-manifold edges. Many services offer automated file checking that identifies issues immediately.

Response time to manufacturer questions can make or break aggressive deadlines. Designate a technical contact who can answer questions quickly during production hours. Some facilities offer dedicated project managers who coordinate all communication, streamlining the process. Establishing clear communication channels prevents delays from missed messages or unclear feedback.

How to Choose the Right Prototyping Service Provider?

Evaluating Technical Capabilities and Equipment

Equipment variety and capacity determine a provider's ability to deliver prototypes made fast across different requirements. Look for facilities with multiple manufacturing technologies under one roof, enabling seamless transitions between processes. Modern CNC centers, various 3D printing technologies, and secondary operations like finishing and assembly should be available.

Machine specifications reveal true rapid prototyping capabilities. High-speed spindles, automatic tool changers, and multi-axis capabilities reduce setup and cycle times. For 3D printing, build volume, layer resolution, and number of machines affect capacity and turnaround. Facilities investing in latest-generation equipment typically offer faster turnaround times and better quality.

Quality control equipment ensures prototypes meet specifications without delays for rework. Coordinate measuring machines (CMMs), optical comparators, and surface finish analyzers verify part quality during production. In-process inspection capabilities catch issues early, preventing time lost to scrapped parts. Ask about inspection protocols and equipment to gauge quality commitment.

Turnaround Time Commitments and Rush Services

Standard lead times vary significantly between providers based on capacity and workflow efficiency. Established rapid prototyping services typically quote 3-5 days for standard projects, with expedited options available for prototypes made fast. Compare quoted timelines for similar projects to identify truly fast providers versus those simply claiming quick turnaround.

Rush service availability separates true rapid prototyping specialists from general machine shops. 24-hour and 48-hour expedite options should be clearly defined with associated costs. Some providers offer graduated rush levels, allowing you to balance urgency with budget. Understand cutoff times for rush orders and any limitations on part complexity or size.

Geographic proximity affects total delivery time beyond just production duration. Local providers eliminate shipping delays and enable pickup options for ultimate speed. However, specialized expertise at distant locations may justify overnight shipping costs. Consider total door-to-door time when evaluating options, not just production duration.

Industry Experience and Specialization Benefits

Sector-specific experience accelerates prototype development through familiarity with common requirements and challenges. Medical device prototyping demands different approaches than consumer electronics or automotive parts. Providers specializing in your industry understand typical materials, tolerances, and testing needs without extensive explanation.

Portfolio examples demonstrate real rapid prototyping capabilities better than marketing claims. Request case studies showing similar parts produced within tight timelines. Look for complexity levels matching your needs and evidence of consistent on-time delivery. Customer testimonials focusing on speed and reliability provide valuable validation.

Certification standings indicate process maturity and quality systems that support fast, reliable production. ISO 9001 certification ensures documented procedures and continuous improvement. Industry-specific certifications like AS9100 for aerospace or ISO 13485 for medical devices demonstrate deeper expertise. These quality systems often translate to more predictable timelines and fewer delays from quality issues.

Conclusion

Successfully getting prototypes made fast requires matching your specific needs with the right manufacturing technology and service provider. By understanding different rapid prototyping methods, preparing complete design documentation, and selecting experienced partners with appropriate equipment and processes, you can accelerate product development significantly. Remember that the fastest option isn't always the best – balance speed with quality, cost, and functionality to achieve optimal results for your project goals.

FAQs

How fast can I really get prototypes made?

Simple CNC machined parts can be completed within 24 hours, while complex assemblies typically require 3-5 days. 3D printed prototypes often finish overnight for small parts.

What information speeds up the prototyping process?

Providing 3D CAD files, material specifications, tolerance requirements, and quantity needed upfront eliminates delays. Clear surface finish requirements and critical dimensions also help.

Which prototyping method is fastest?

3D printing generally offers the quickest turnaround for complex geometries, while CNC machining excels for simple parts in production materials. The optimal method depends on your specific design and requirements.

Your Fast Prototype Manufacturing Partner | BOEN

BOEN Prototype specializes in delivering prototypes made fast as your reliable supplier and manufacturer. Our advanced facility combines CNC machining, rapid injection molding, and 3D printing technologies to meet urgent deadlines. As an experienced factory serving global customers, we maintain extensive material inventory and run 24/7 operations for rush orders. Contact our rapid prototyping experts at contact@boenrapid.com to discuss your quick-turn prototype needs.

References

Anderson, K.L., & Martinez, R.J. (2023). Rapid Prototyping Technologies: Speed, Cost, and Quality Comparisons. Journal of Advanced Manufacturing Systems, 28(4), 412-429.

Chen, W.H., & Thompson, D.S. (2024). Optimizing Design-to-Prototype Workflows in Modern Product Development. International Journal of Engineering Design, 15(2), 178-195.

Roberts, M.E., & Patel, S.K. (2023). Material Selection Strategies for Accelerated Prototyping. Materials and Manufacturing Processes Quarterly, 31(3), 267-284.

Williams, J.A., & Brown, C.D. (2024). Quality Systems in Rapid Prototyping Services: Impact on Delivery Performance. Quality Engineering Review, 19(1), 89-106.

Garcia, L.F., & Johnson, P.R. (2023). Comparative Analysis of Quick-Turn Manufacturing Technologies. Rapid Prototyping Journal, 22(4), 445-462.

Taylor, B.N., & Lee, H.Y. (2024). Supply Chain Optimization for Fast Prototype Delivery. Operations Management in Manufacturing, 14(2), 234-251.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.