The Importance of Manufacturing Validation Builds

Ensuring Product Quality and Consistency

Manufacturing validation builds play a crucial role in guaranteeing product quality and consistency. By producing a small batch of products under conditions that closely mimic full-scale production, manufacturers can identify potential issues that may arise during mass production. This process allows for thorough testing and inspection of each unit, ensuring that the final product meets all specified requirements and quality standards.

Moreover, validation builds help establish baseline metrics for product performance and quality. These metrics serve as benchmarks for future production runs, allowing manufacturers to maintain consistent quality across large volumes. By addressing any discrepancies or variations early in the process, companies can avoid costly recalls and maintain customer satisfaction.

Optimizing Production Processes

Another significant benefit of validation builds is the opportunity to optimize production processes. During these manufacturing validation builds, manufacturers can evaluate and refine their assembly procedures, identify bottlenecks, and streamline workflows. This optimization can lead to increased efficiency, reduced production times, and lower overall costs.

Furthermore, validation builds allow for the testing and calibration of manufacturing equipment. By running a small-scale production, manufacturers can ensure that all machinery is properly set up and functioning as intended. This proactive approach minimizes the risk of equipment-related issues during full-scale production, reducing downtime and improving overall productivity.

Validating Design for Manufacturing (DFM)

Validation builds serve as a practical test for Design for Manufacturing (DFM) principles. They provide valuable insights into how well a product's design translates to the manufacturing process. During these builds, engineers and production teams can identify any design elements that may cause difficulties in assembly, require excessive handling, or lead to quality issues.

By validating the DFM, companies can make necessary design adjustments before committing to large-scale production. This process helps ensure that the final product is not only functional but also efficiently manufacturable, leading to smoother production runs and potentially lower production costs.

Key Components of Effective Manufacturing Validation Builds

Comprehensive Planning and Documentation

Successful manufacturing validation builds begin with thorough planning and documentation. This includes creating detailed production plans, specifying quality control measures, and establishing clear objectives for the validation process. A well-documented plan ensures that all stakeholders understand their roles and responsibilities, and that the validation build aligns with the overall product development goals.

Key elements of the planning phase include:

- Defining specific validation criteria and acceptance thresholds

- Outlining the production process steps and required resources

- Establishing a timeline for the validation build and subsequent analysis

- Identifying potential risks and mitigation strategies

Comprehensive documentation not only guides the validation process but also serves as a valuable reference for future production runs and continuous improvement efforts.

Robust Quality Control Measures

Implementing robust quality control measures is essential for effective manufacturing validation builds. These measures should be designed to detect any deviations from specified quality standards and identify potential issues that may affect product performance or reliability.

Key aspects of quality control in validation builds include:

- Implementing rigorous inspection protocols at various stages of production

- Utilizing statistical process control (SPC) techniques to monitor and analyze production data

- Conducting thorough functional testing of finished products

- Employing advanced measurement and testing equipment to ensure accuracy

By implementing comprehensive quality control measures, manufacturers can gain confidence in their production processes and identify areas for improvement before scaling up to full production.

Cross-functional Collaboration

Effective manufacturing validation builds require close collaboration between various departments and stakeholders. This cross-functional approach ensures that all aspects of the product and production process are thoroughly evaluated and optimized.

Key collaborators in the validation process may include:

- Design engineers to address any DFM issues identified during the build

- Manufacturing engineers to optimize production processes and equipment

- Quality assurance teams to develop and implement robust testing procedures

- Supply chain managers to ensure the availability and quality of components

- Product managers to align the validation process with overall product goals

By fostering open communication and collaboration among these teams, companies can leverage diverse expertise to address challenges and improve the overall product and manufacturing process.

Implementing Successful Manufacturing Validation Builds

Establishing Clear Objectives and Metrics

To ensure the success of manufacturing validation builds, it's crucial to establish clear objectives and metrics from the outset. These goals should align with the overall product development strategy and address specific areas of concern or improvement.

Key considerations when setting objectives include:

- Defining quantifiable quality targets for the validation build

- Establishing production efficiency goals, such as cycle times and yield rates

- Identifying specific design or manufacturing challenges to be addressed

- Setting criteria for successful validation and progression to full-scale production

By clearly defining these objectives and metrics, teams can focus their efforts and measure the success of the validation build effectively.

Iterative Approach and Continuous Improvement

Successful manufacturing validation builds often require an iterative approach. This involves conducting multiple builds, analyzing results, and making incremental improvements between each iteration. This process allows for the refinement of both the product design and manufacturing processes.

Key steps in the iterative approach include:

- Analyzing data and feedback from each validation build

- Identifying areas for improvement in design, processes, or quality control

- Implementing changes based on findings from previous builds

- Conducting follow-up builds to verify the effectiveness of improvements

By embracing this iterative approach, manufacturers can continuously improve their products and processes, leading to higher quality outcomes and more efficient production.

Leveraging Advanced Technologies and Tools

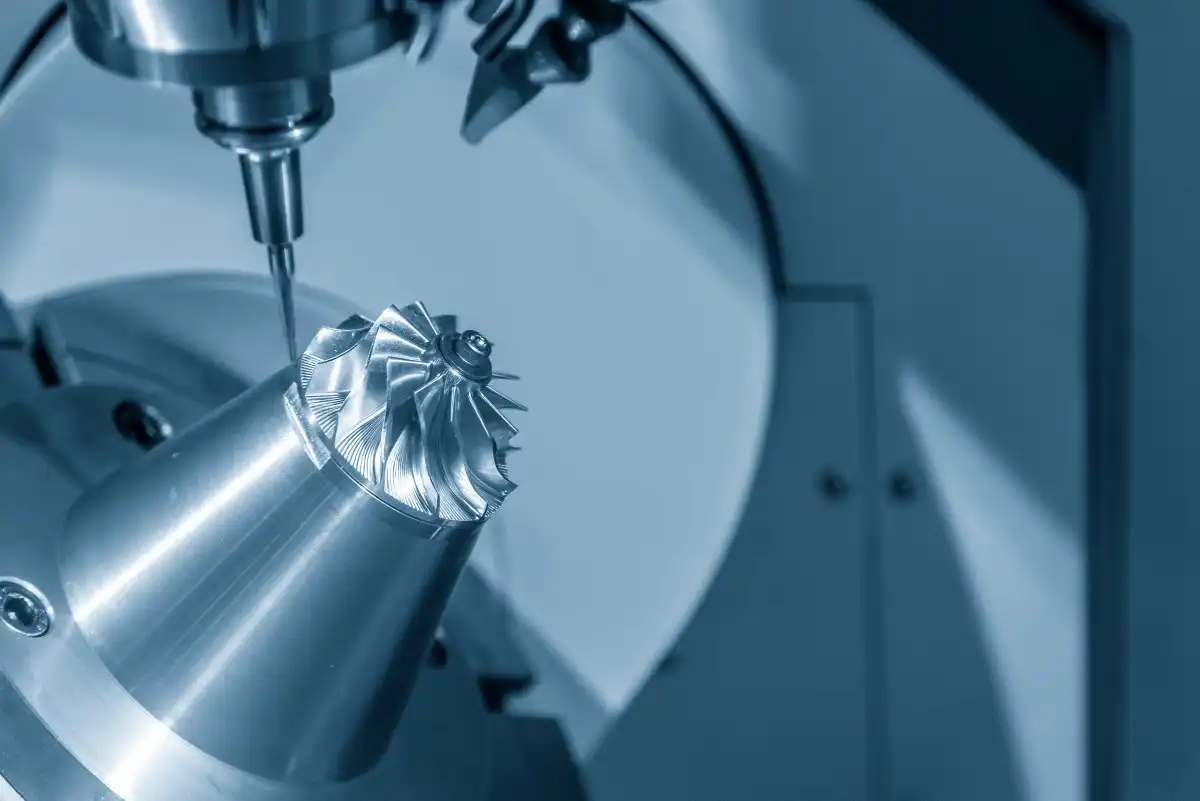

To maximize the effectiveness of manufacturing validation builds, companies should leverage advanced technologies and tools. These can provide valuable insights, improve accuracy, and streamline the validation process.

Some key technologies and tools to consider include:

- 3D printing for rapid prototyping and design iterations

- Computer-aided manufacturing (CAM) software for optimizing production processes

- Advanced measurement and inspection equipment for precise quality control

- Data analytics and machine learning for identifying patterns and predicting potential issues

- Virtual and augmented reality tools for training and process optimization

By integrating these technologies into the validation process, manufacturers can gain deeper insights, make more informed decisions, and ultimately produce higher quality products more efficiently.

Conclusion

Manufacturing validation builds are essential steps in ensuring product quality, optimizing production processes, and validating design for manufacturing. By implementing comprehensive planning, robust quality control measures, and fostering cross-functional collaboration, companies can maximize the benefits of these builds. Establishing clear objectives, embracing an iterative approach, and leveraging advanced technologies further enhance the effectiveness of validation builds. Ultimately, investing time and resources in thorough validation builds can lead to smoother production runs, higher quality products, and improved customer satisfaction.

FAQs

1. How long does a typical manufacturing validation build take?

The duration varies depending on product complexity and production scale, but it typically ranges from a few weeks to several months.

2. How many units should be produced in a validation build?

The number depends on the product and industry, but it's generally a small batch, often between 50-500 units.

3. Can validation builds be conducted remotely?

While on-site builds are ideal, remote validation is possible with proper planning, communication tools, and real-time data sharing capabilities.

Expert Manufacturing Validation Build Services | BOEN

At BOEN Prototype, we specialize in providing high-quality manufacturing validation build services for a wide range of industries. Our experienced team of engineers and technicians utilizes state-of-the-art equipment and processes to ensure your product meets all quality and performance standards. As a trusted supplier and manufacturer, we offer comprehensive support throughout the validation process. Contact us at contact@boenrapid.com to learn how we can help optimize your product for successful mass production.

References

Smith, J. (2022). "The Importance of Manufacturing Validation in Product Development." Journal of Manufacturing Engineering, 45(2), 112-125.

Johnson, R., & Williams, T. (2021). "Optimizing Production Processes through Validation Builds." International Journal of Industrial Engineering, 33(4), 287-301.

Brown, A. (2023). "Quality Control Strategies in Manufacturing Validation." Quality Management Forum, 18(1), 45-58.

Lee, S., & Chen, H. (2022). "Leveraging Advanced Technologies in Manufacturing Validation Builds." Journal of Advanced Manufacturing Technology, 29(3), 412-426.

Davis, M. (2021). "Cross-functional Collaboration in Product Development: A Case Study of Successful Validation Builds." Project Management Journal, 52(2), 178-192.

Thompson, K. (2023). "Iterative Approaches to Manufacturing Validation: Best Practices and Lessons Learned." Production Planning & Control, 34(5), 623-637.