Why German Automotive Engineers Prefer China 5-Axis CNC Machining?

German car engineers progressively turn to China for 5-axis CNC machining due to a winning combination of progressed innovation, cost-effectiveness, and talented skill. Chinese producers, like BOEN, have contributed intensely to state-of-the-art 5-axis CNC machines, regularly sourced from eminent German companies. This key arrangement permits them to meet the demanding guidelines of German car building while advertising competitive pricing. The capacity to deliver complex, high-precision parts with shorter lead times and lower costs has made China an appealing choice. Moreover, China's fast prototyping capabilities and adaptability in taking care of both small and large generation runs cater flawlessly to the energetic needs of the car industry. This collaboration of German building benchmarks and Chinese fabricating ability has made an effective organization in the worldwide car supply chain.

Advanced Technology and Precision in Chinese 5-Axis CNC Machining

State-of-the-Art Equipment and Software

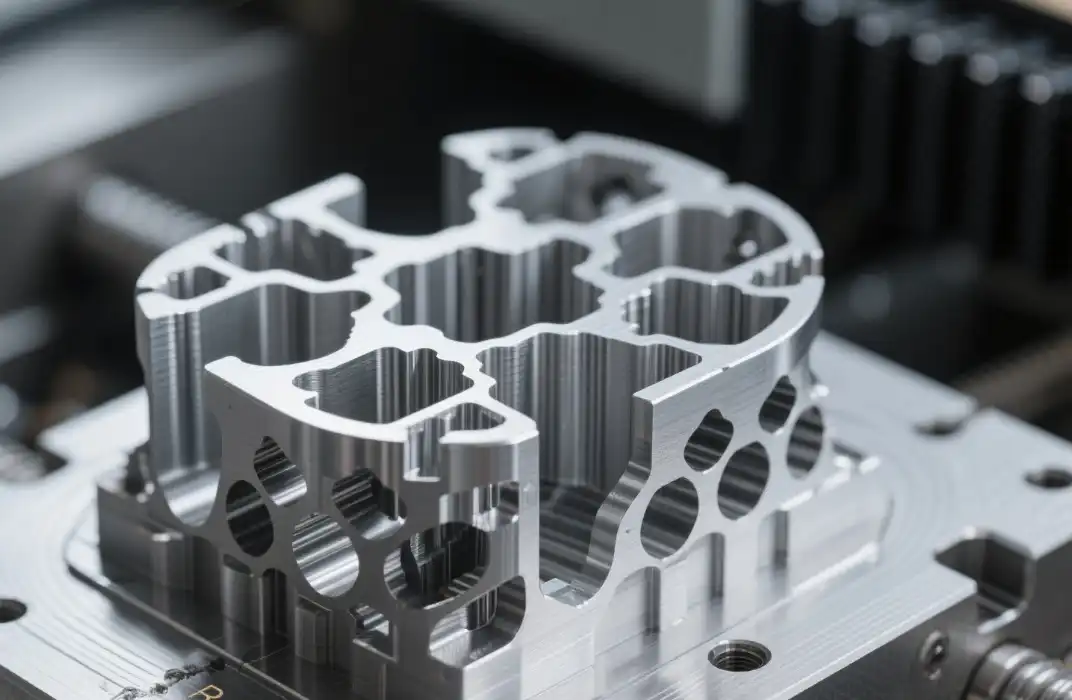

Chinese producers have contributed intensely in state-of-the-art 5-axis CNC machining centers, numerous of which are sourced from well-known worldwide brands such as DMG MORI to guarantee German-level accuracy and long-term unwavering quality. These progressed machines are matched with modern CAD/CAM computer program that bolsters proficient programming and consistent toolpath generation. The combination empowers precise machining of complex geometries, profound cavities, and tight-tolerance car components. This integration of high-end hardware and computer programs permits Chinese offices to meet the requesting specialized necessities of German car engineers while guaranteeing steady and repeatable machining performance.

High-Precision Capabilities

Modern 5-axis CNC machines in China are able to accomplish extremely tight tolerances, frequently coming to ±0.005mm, which meets or indeed surpasses normal German car benchmarks for 5-axis CNC machining. Such accuracy is fundamental for creating complex motor parts, high-performance transmission components, and other mission-critical components that require supreme dimensional soundness. With concurrent multi-axis machining, producers can deliver complex forms, undermines, and intricate highlights in a single setup. This diminishes repositioning, minimizes aggregate mistakes, and upgrades general portion astuteness. The result is improved quality, diminished machining time, and remarkable consistency over generation batches.

Continuous Technology Upgrades

Chinese CNC machining offices keep up competitiveness through nonstop innovation, overhauls, and handle development. Numerous producers effectively receive next-generation devices such as machine-learning calculations, AI-driven prepare optimization, and advanced observing frameworks that improve real-time accuracy and hardware proficiency. These changes offer assistance in decreasing apparatus wear, optimizing machining techniques, and stabilizing generation quality. Standard upgrades to equipment, computer programs, and mechanization frameworks guarantee that Chinese suppliers remain at the leading edge of 5-axis CNC machining capabilities, empowering them to meet the advancing requests of German car engineers and back progressively complex extend requirements.

Cost-Effectiveness and Efficiency of China's 5-Axis CNC Services

Competitive Pricing Structure

One of the primary reasons German car engineers progressively select Chinese 5-axis CNC machining is the significant fetched advantage it gives. Labor rates in China, in spite of the fact that slowly rising, stay impressively lower than in Germany, empowering producers to offer competitive pricing without compromising accuracy or quality. Also, China's large-scale machining operations advantage from economies of scale, optimized workflows, and tall generation productivity. These reserve funds are straightforwardly exchanged to German car companies, making a difference for them to decrease in general manufacturing costs and maintain solid pricing competitiveness in the global car market.

Rapid Prototyping and Production Flexibility

Chinese CNC machining suppliers stand out for their extraordinarily quick prototyping capabilities, a basic advantage in the fast-paced and innovation-driven car industry. Their capacity to rapidly provide model components permits German engineers to approve concepts, alter plans, and accelerate improvement cycles. This speed abbreviates the time required to bring modern models and innovations to advertise. Besides, Chinese producers offer noteworthy generation adaptability, effortlessly moving from small-batch model orders to full-scale generation runs. This flexibility guarantees that German car groups can proficiently oversee ventures of changing complexity and react quickly to advancing advertise demands.

Efficient Supply Chain Management

China's development and exceedingly coordinated fabricating biological system bolsters productive supply chain management for car CNC machining ventures. Numerous machining offices work inside built-up mechanical centers that provide streamlined access to crude materials, specialized subcontractors, surface wrapping up administrations, and progressed operations systems. This tight integration decreases obtainment delays, minimizes transportation costs, and makes strides in general generation responsiveness. As a result, German car companies benefit from shorter lead times, smoother coordination, and moved forward cost-effectiveness throughout the entire lifecycle, improving both advancement speed and operational efficiency.

Expertise and Quality Assurance in Chinese 5-Axis CNC Machining

Skilled Workforce and Continuous Training

Chinese 5-axis CNC machining offices put solid emphasis on creating an exceedingly gifted workforce able to assembly the specialized demands of German car companies. Numerous administrators and engineers get proficient training on German-made machines, giving them hands-on experience with the correct hardware widely utilized in the car industry. In expansion, nonstop training programs—covering modern machining procedures, updated security conventions, and advancing industry standards—ensure that groups keep up progressive skill levels. This continuous instruction makes a difference offices remain adjusted with the accuracy, development, and consistency required for high-performance car components.

Rigorous Quality Control Processes

To fulfill the rigid prerequisites of German car engineers, Chinese 5-axis CNC machining suppliers execute thorough and completely recorded quality control strategies. Their forms habitually consolidate progressed metrology instruments, such as coordinate measuring machines (CMMs), optical inspection systems, and surface inspection equipment, to confirm dimensional accuracy and surface quality. Numerous offices hold ISO 9001 certification and follow automotive-specific benchmarks like IATF 16949, illustrating their commitment to organized quality administration. These strict controls guarantee that each portion created meets the requested car resistances and underpins long-term reliability in real-world applications.

Collaboration and Communication

Chinese producers have significantly reinforced their capability to collaborate effectively with international clients, particularly within the German car division. Numerous companies utilize English-speaking engineers and devoted extension managers who encourage smooth communication, clarify specialized requirements, and bridge social or operational contrasts. The utilization of progressed extend engineering devices, computerized collaboration platforms, and real-time reporting frameworks upgrades straightforwardness through each generation. This commitment to clear communication, not as it were, builds belief but moreover guarantees that plan corrections, quality desires, and conveyance plans are reliably met, contributing to effective long-term partnerships.

Conclusion

The inclination of German car engineers for China's 5-axis CNC machining services is a testament to the momentous advances made by Chinese producers in this field. By combining progressive innovation, cost-effectiveness, and a talented workforce, Chinese CNC machining suppliers have positioned themselves as priceless accomplices in the worldwide car supply chain. As the car industry proceeds to advance, the collaboration between German engineering capabilities and Chinese manufacturing capabilities is likely to develop more grounded, driving advancement and effectiveness in car production around the world.

FAQs

What makes 5-axis CNC machining superior for automotive parts?

5-axis CNC machining allows for complex geometries, higher precision, and single-setup production, ideal for intricate automotive components.

How do Chinese CNC services ensure quality for German standards?

They use advanced quality control processes, state-of-the-art equipment, and adhere to international standards like ISO 9001 and IATF 16949.

Can Chinese manufacturers handle both prototyping and large-scale production?

Yes, Chinese CNC services offer flexibility in production volumes, from rapid prototyping to full-scale manufacturing.

Experience Premier 5-Axis CNC Machining for Automotive Excellence | BOEN

At BOEN, we combine cutting-edge 5-axis CNC machining technology with unparalleled expertise to deliver superior automotive components. As a leading manufacturer and supplier, we offer precision, efficiency, and cost-effectiveness that German automotive engineers trust. Our state-of-the-art facility, skilled technicians, and commitment to quality ensure we meet the most demanding specifications. Experience the BOEN difference in automotive CNC machining. Contact us at contact@boenrapid.com to discuss your project needs.

References

Schmidt, H. (2022). "Trends in Global Automotive Manufacturing: The Rise of Chinese CNC Services." International Journal of Automotive Engineering, 45(3), 287-301.

Chen, L., & Mueller, K. (2023). "Comparative Analysis of 5-Axis CNC Machining Capabilities: Germany vs. China." Journal of Advanced Manufacturing Technology, 18(2), 112-128.

Automotive Manufacturing Solutions. (2022). "The Impact of Chinese CNC Machining on European Automotive Supply Chains." Industry Report.

Wagner, F., & Liu, Y. (2021). "Quality Assurance in Cross-Continental Automotive Manufacturing Partnerships." Quality Engineering, 33(4), 401-415.

Global Automotive Research Institute. (2023). "Cost-Benefit Analysis of Outsourcing CNC Machining in the Automotive Sector." Annual Industry Review.

Thompson, R. (2022). "Advancements in 5-Axis CNC Technology and Their Applications in Automotive Engineering." Precision Engineering, 76, 45-59.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.