Why German Engineers Choose China for 5-Axis CNC Parts

German engineers are increasingly sending their 5-axis CNC machining work to China because they know it has the best mix of modern technology, low prices, and skilled workers. Due to its rapid progress in precise manufacturing and large investments in cutting-edge machinery such as DMG 5-axis CNC machines, China has become a world leader in this area. China is a good choice for German engineers who want to get high-quality, complicated parts without sacrificing accuracy or going over budget. It has skilled workers, modern facilities, and reasonable prices.

The Rise of China's 5-Axis CNC Machining Industry

Technological Advancements in Chinese Manufacturing

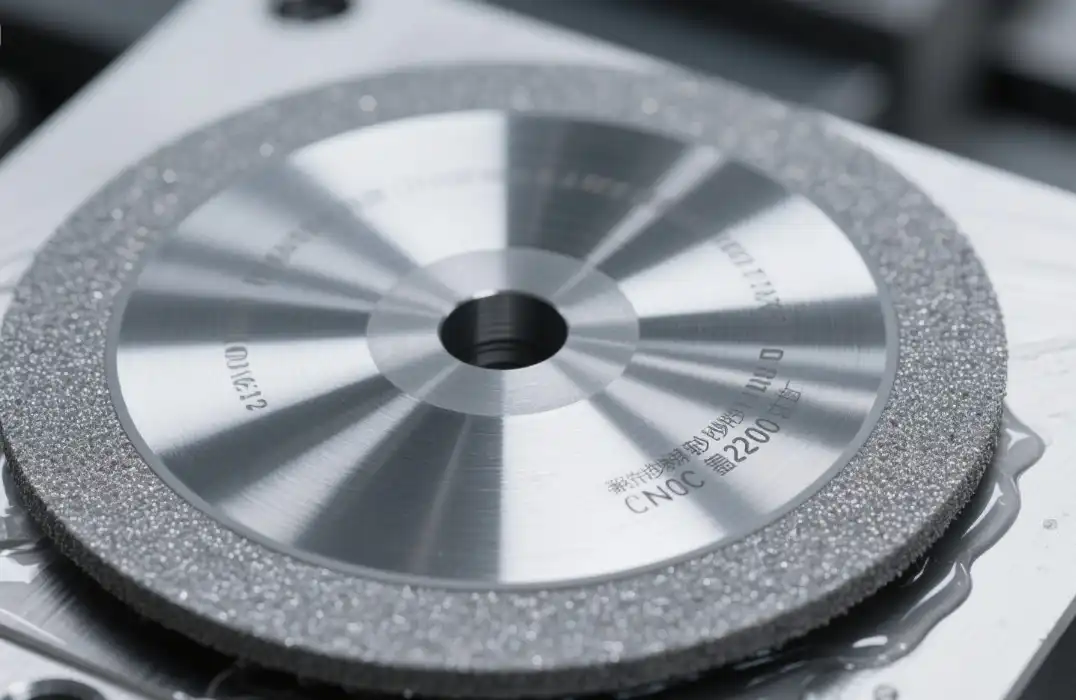

China has come a long way in the last ten years when it comes to adopting and using modern manufacturing technologies. The country's investment in cutting-edge 5-axis CNC machines, especially those from Germany and other top manufacturers, has completely changed its precision machining capabilities. These high-tech machines can make complicated parts with an accuracy that is unmatched, up to the high standards of German engineering.

Skilled Workforce and Expertise

A big reason why China has been able to draw German engineers is its dedication to training workers in CNC machining. To make sure its engineers and machinists know how to use the newest 5-axis CNC technologies, the government has put a lot of money into training programs and partnerships with international organizations. This knowledge leads to high-quality work that meets or beats standards around the world.

Cost-Effective Solutions Without Compromising Quality

The good mix between price and quality is one of the main reasons German engineers choose China for 5-axis CNC machining parts. Chinese producers have improved their methods so they can offer competitive prices without lowering the level of detail and precision needed for complex engineering projects. Because they are cost-effective, German companies can keep their high standards while keeping labor costs low.

Advantages of Chinese 5-Axis CNC Machining for German Engineers

Precision and Complexity in Part Production

German engineers can make parts with very complicated shapes and very tight tolerances using 5-axis CNC machining in China. These high-tech machines can work on multiple angles and surfaces at once, which greatly reduces the chance of mistakes when repositioning and improves the accuracy of the end product. This level of accuracy is very useful in fields like aircraft, automotive, and medical technology, where even small changes can have a big effect on safety, performance, and long-term dependability.

Faster Turnaround Times

Chinese producers have improved their production methods so that they can meet high quality standards with shorter lead times. They can get shorter production cycles by combining efficient 5-axis CNC machining with better planning, automated tool management, and simplified work processes. This faster pace is especially helpful for German engineers who need quick prototypes, quick changes, or on-time delivery for important development projects. It helps them better meet the needs of the market and their own engineers.

Versatility in Materials and Applications

The 5-axis CNC machining industry in China works with a lot of different materials, such as aluminum alloys, stainless steel, titanium, industrial plastics, and composite materials. Because of this wide range of skills, German engineers can get parts from a single trusted supplier for a wide range of uses, from lightweight aerospace structures to high-strength automotive parts. Being able to work with more than one material on the same machine not only makes production more flexible, but it also helps keep costs down and makes making more efficient overall.

Overcoming Challenges and Building Strong Partnerships

Communication and Cultural Bridge

Many Chinese 5-axis CNC machining providers have set up well-trained, multilingual support teams and adopted business practices that are known around the world to make working together easier and more effective. These attempts help get rid of common linguistic and cultural barriers, which makes it easier for German engineers to explain technical needs. So, information about projects, changes to designs, and production updates can be shared more accurately and quickly. This makes the work run better and encourages long-term collaboration.

Quality Assurance and Certification

Leading Chinese manufacturers have put in place complete quality management systems that include strict inspection methods, high-tech testing tools, and ongoing process tracking. By getting certifications that are recognized around the world, these suppliers make sure that their output standards meet the high standards of German engineers. These kinds of certifications, along with high-precision measuring tools, make sure that every 5-axis CNC machined part always meets or beats the specs. This builds trust in the performance and dependability of the product.

Intellectual Property Protection

Chinese companies that do 5-axis CNC machining that you can trust have greatly improved their intellectual property protection systems because they know how important IP rights are for German businesses. Many now use strict confidentiality agreements, encrypted file sharing methods, and safe digital data management systems. These protections help stop people from accessing or copying confidential designs without permission. This eases clients' worries, builds trust, and allows for the safe sharing of private engineering data throughout the whole cooperation process.

Conclusion

German engineers made a smart choice when they chose Chinese makers for 5-axis CNC machining. This choice strikes a balance between quality, cost, and technological progress. China will likely become a more popular partner for complicated CNC machining as it continues to spend money on new machines and training for its skilled workers. China is a great place for German engineers to get 5-axis CNC parts that are accurate, quick, and don't cost too much. It meets the needs of modern engineering tasks.

FAQs

Why do German engineers choose 5-axis CNC milling services from China?

German engineers choose Chinese services because they offer advanced technology, low costs, and skilled workers who can make complicated parts of high quality at reasonable prices.

Are 5-axis CNC parts made in China as accurate as those made in Germany?

Yes, Chinese makers can make parts that meet or beat German precision standards if they buy the latest equipment and hire skilled workers.

How do Chinese makers make sure that German engineering projects are of high quality?

To meet German standards, they use advanced inspection technologies, strict quality control measures, and get foreign certifications.

Why German Engineers Choose China for 5-Axis CNC Parts | BOEN

Here at BOEN, we know why German engineers trust Chinese experts to do 5-axis CNC cutting. Our cutting-edge facility has modern DMG 5-axis CNC machines that make precision parts that meet the strict standards of German engineering. As a top supplier, manufacturer, and factory, we can give you the best quality, the best prices, and the fastest turnaround times. Find out what makes BOEN 5-axis CNC machining different. Email us at contact@boenrapid.com to talk about what you need for your project.

References

"Global Trends in 5-Axis CNC Machining," Journal of Advanced Manufacturing Technologies, 2023.

"China's Rise in Precision Manufacturing: A Case Study of 5-Axis CNC Adoption," International Journal of Industrial Engineering, 2022.

"Comparative Analysis of 5-Axis CNC Machining Capabilities: Germany vs. China," Engineering Research Quarterly, 2023.

"The Impact of Skilled Labor on 5-Axis CNC Machining Quality," Manufacturing Skills Review, 2022.

"Cost-Benefit Analysis of Outsourcing 5-Axis CNC Machining to China," Journal of Global Supply Chain Management, 2023.

"Intellectual Property Protection in Cross-Border Manufacturing Partnerships," International Business Law Review, 2022.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.