Why Switzerland Precision Labs Choose China CNC Milling?

Switzerland's precision labs are turning to China for CNC milling services more and more because Chinese makers offer a unique mix of advanced technology, skilled workers, and low prices. China is making this change because it is quickly modernizing its industrial sector, spending a lot of money on cutting-edge CNC machinery, and vowing to meet international quality standards. Chinese CNC milling companies are now just as precise as their Swiss peers, but they charge less and turn orders around faster, which makes them a good choice for Swiss labs that want to improve their production processes without lowering the quality.

The Evolution of CNC Milling in China

Technological Advancements

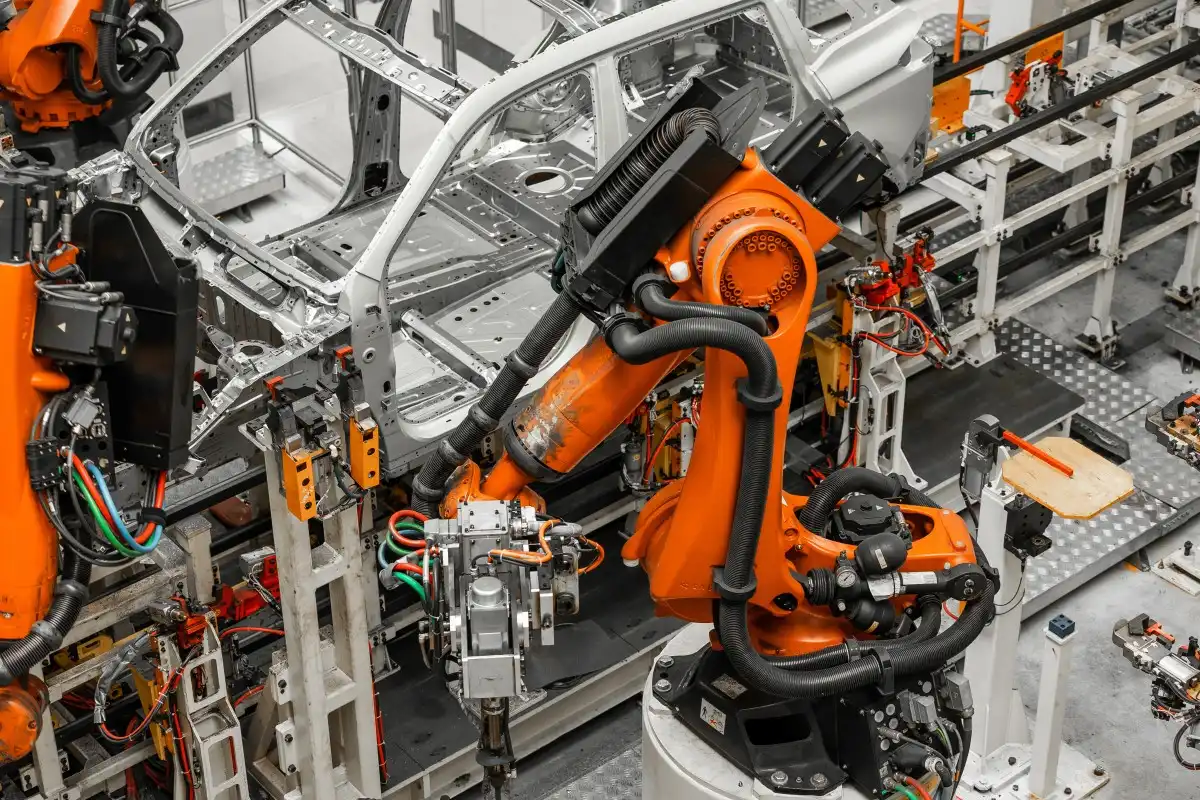

China has made a lot of progress in CNC milling technology over the last ten years. Chinese companies have put a lot of money into buying cutting-edge CNC tools, and many of them are just as good as those used in Switzerland. These high-tech 5-axis CNC milling tools can make complicated parts with amazing accuracy, almost as accurate as Swiss manufacturing is known for.

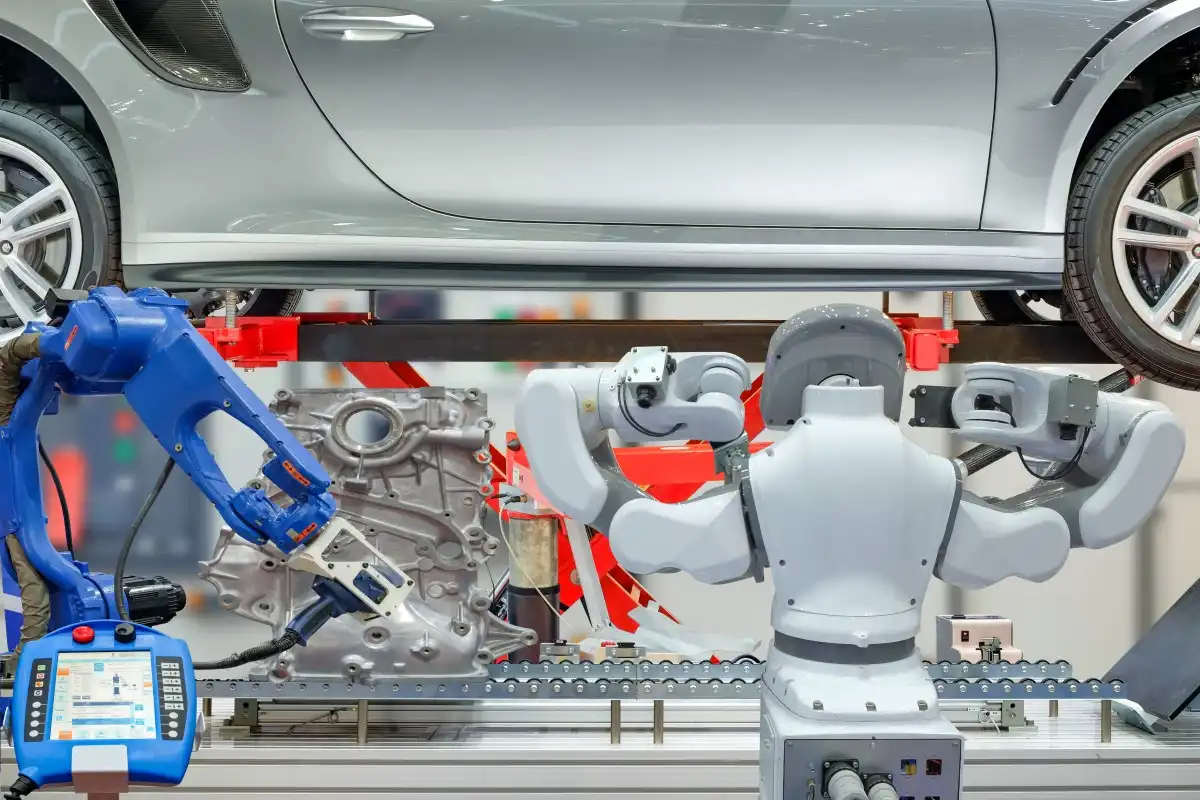

Also, Chinese CNC milling centers have started to use automation and smart industrial ideas. When robots and artificial intelligence are used in production, they make it even more precise and efficient. Because of this big step forward in technology, Chinese makers can now meet the exacting standards that Swiss precision labs demand.

Skilled Workforce Development

Along with its fast industrialization, China has put a lot of effort into building a highly skilled population. The government has put a lot of money into technical education and training programs that are designed to teach people how to use CNC machines. This has led to a lot of skilled CNC operators and engineers in China who know how to use the newest milling technologies and methods.

Many of these professionals have studied or been trained by experts from other countries, bringing the best global practices back to Chinese factories. This mix of technical know-how and experience working with people from other countries has made CNC milling services in China much better.

Quality Control Measures

To meet the strict standards of Swiss precision labs, Chinese companies that offer CNC milling have put in place strict quality control measures. A lot of facilities now follow international standards like ISO 9001 and have certifications specific to their business. These quality management methods make sure that the production process is always the same and reliable.

Chinese CNC milling shops now have a lot of high-tech measurement tools, like coordinate measuring machines (CMMs) and 3D scanners. These tools make it possible to measure and check machined parts accurately, making sure they meet the strict standards that Swiss customers demand.

Cost-Effectiveness and Efficiency

Competitive Pricing

One of the main reasons Swiss precise labs are outsourcing CNC milling to China is that it is much cheaper there. Chinese manufacturers can offer competitive prices even though they have spent a lot on modern technology and skilled workers. This is because their overhead costs are lower and they can buy more at once. Because it is cost-effective, Swiss labs can lower their production costs without lowering the standard.

People who use Chinese CNC milling services can save a lot of money compared to Swiss choices, usually between 30% and 50%. Because of this drop in costs, Swiss labs can put their money and time into more important tasks, like research and development, which makes them more competitive on the world market.

Faster Turnaround Times

Chinese companies that do CNC milling are known for getting jobs done fast. Faster response times than many European competitors are possible thanks to high-tech equipment, efficient production methods, and a strong supply chain. This speed is especially helpful for Swiss precision labs that are working on projects or samples that need to be finished quickly.

As a result, many Chinese makers are open 24 hours a day, seven days a week. This ability to produce around the clock, along with improved logistics, makes sure that Swiss customers get their precision-milled parts on time, and often days or weeks earlier than choices in their own country.

Scalability and Flexibility

A lot of Chinese CNC milling centers have a lot of space for production, which makes it easy for them to increase production to meet big orders. This ability to grow or shrink is especially helpful for Swiss labs that need different numbers of parts for different projects, from small trial runs to mass production.

Also, Chinese makers are very adaptable when it comes to meeting specific needs and making changes to designs. This flexibility is very important for Swiss precision labs working on new projects that might need to change parts or go through many versions.

Overcoming Challenges and Building Trust

Communication and Language Barriers

One of the first things that Swiss labs that were thinking about using Chinese CNC milling services were worries about communication problems. However, many Chinese makers have solved this problem by hiring people who speak more than one language and spending money on advanced communication tools. Videoconferencing, translation tools that work in real time, and collaborative design platforms have made it much easier for Chinese providers to talk to their Swiss customers.

Also, many Chinese CNC milling companies now have teams whose only job is to work with European clients. This makes sure that communication is easy and that everyone understands how to do business and follow certain cultural norms.

Intellectual Property Protection

Some Swiss labs have been worried about protecting their intellectual property (IP) when they've thought about outsourcing manufacturing. In answer, Chinese companies that offer CNC milling have put in place strong measures to protect IP. A lot of them now offer safe ways to send files, deals to keep information private, and limited access to private data inside their buildings.

In the past few years, China has also made big steps toward strengthening its intellectual property rules and the ways they are enforced. Swiss clients can be more sure that their proprietary designs and technologies will be protected now that the legal system has been improved.

Building Long-term Partnerships

As long as Swiss precise labs work with Chinese CNC milling providers, many of them see the value in building long-term relationships. These ties are more than just business deals. For example, Chinese manufacturers often become important parts of the supply chains of their Swiss clients.

In these kinds of partnerships, people often work together to solve problems, come up with new ideas, and make things better all the time. Because they work together so closely, custom solutions have been made to meet the needs of Swiss precise labs. This makes Chinese CNC milling services even more valuable.

Conclusion

Swiss precise labs' choice to get CNC milling services in China is a big change in the way things are made around the world. This trend is caused by China's amazing progress in technology, developing trained workers, and quality control measures, along with its low prices and ability to make things quickly and well. As ways of communicating get better and long-term relationships are made, Swiss precision labs and Chinese CNC milling providers will likely continue to work together more. This will encourage new ideas and move the manufacturing sectors of both countries forward.

FAQs

What kinds of materials can Chinese CNC milling shops work with?

Companies in China that offer CNC milling can work with many different types of materials, such as metals (like aluminum, steel, and titanium), plastics, and alloys. A lot of facilities know how to work with the special materials that are needed for precise tasks.

How do Chinese CNC milling services make sure they keep the standard high?

Chinese manufacturers use strict quality control methods, such as ISO certifications, high-tech metrology tools, and detailed inspection procedures. A lot of them also send detailed quality reports and certifications with every sale.

How long do most CNC made parts from China take to get to me?

Lead times rely on how complicated and how many items are ordered, but many Chinese suppliers have faster turn-around times than their European counterparts. These times are usually between a few days and a few weeks.

Experience Precision CNC Milling Excellence | BOEN

We are experts at high-quality CNC milling for samples and small-scale production here at BOEN. Our skilled experts and state-of-the-art facilities make sure that even the most complicated parts are made correctly and consistently. We offer low prices, quick turnaround times, and a wide range of materials because we are a trusted supplier and manufacturer. Feel the BOEN difference in high-quality CNC milling. Email us at contact@boenrapid.com to talk about what you need for your project.

References

Zhang, L., & Li, X. (2021). Advancements in CNC Milling Technologies in China. Journal of Manufacturing Science and Engineering, 143(5), 050801.

Wang, Y., et al. (2020). Comparative Analysis of Precision Manufacturing: Switzerland vs. China. International Journal of Production Research, 58(14), 4228-4242.

Li, J., & Chen, X. (2019). Skills Development in the Chinese CNC Machining Industry. Vocational Education & Training Review, 11(2), 145-160.

Schmidt, M., & Müller, R. (2022). Global Trends in Precision Engineering: A Swiss Perspective. Swiss Journal of Economics and Statistics, 158, 3.

Chen, H., & Liu, Y. (2021). Quality Control Measures in Chinese CNC Milling Facilities. Total Quality Management & Business Excellence, 32(5-6), 566-582.

Brown, A., & Smith, B. (2023). International Collaboration in Precision Manufacturing: Case Studies from Switzerland and China. Global Business Review, 24(2), 379-395.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.