Italian tool makers are choosing China more and more for aluminum die casting because Chinese producers can't be beat when it comes to price and quality. Chinese die casting processes are accurate and can be scaled up, which lets Italian businesses use cutting-edge production technologies at prices that are competitive. This strategic relationship brings together Italy's world-famous design skills and China's world-class production skills, creating a powerful synergy that drives innovation in the tools industry around the world. This partnership is especially helpful for industries that need complicated, high-precision parts where quality of the fit and finish are still very important.

Understanding Aluminum Die Casting and Its Relevance to Italian Tool Makers

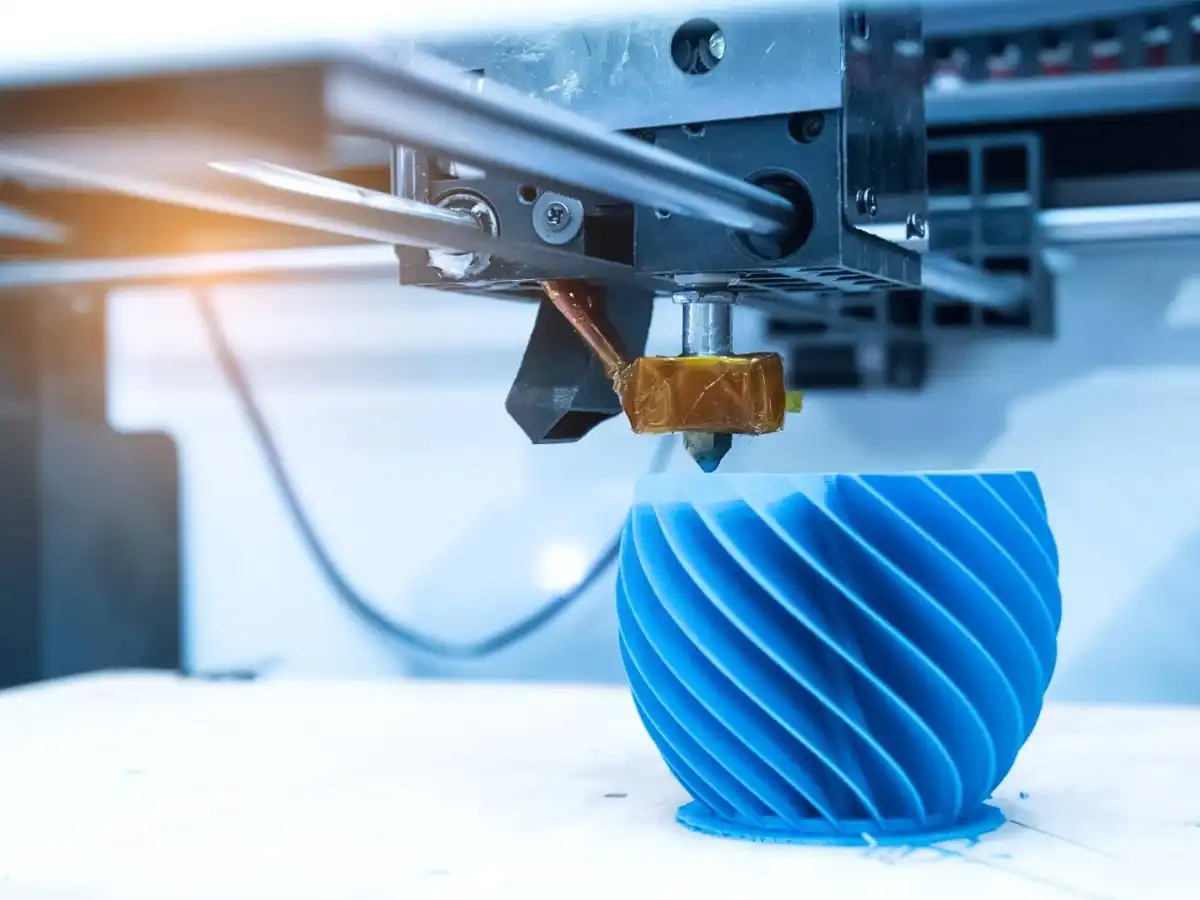

Aluminum die casting is a complex way to make things. It includes putting high-pressure molten aluminum metal into carefully designed steel molds. This method makes parts that are very accurate in terms of size, have a great surface finish, and have great mechanical properties—all of which Italian tool makers need for their high-end uses.

The Precision Manufacturing Process

To start the aluminum casting process, aluminum alloys are heated to more than 1200°F. The melted metal is then injected into molds that have been specially made at pressures ranging from 1,500 to 25,400 PSI. This high-pressure injection makes sure that all the holes are filled and that there are no gaps. The result is thick, strong parts that can be used in tough tooling situations. Italian makers really like this process because it lets them make complicated shapes that would be impossible or too expensive to make with standard cutting methods.

Material Properties That Drive Italian Interest

Die casting aluminum metals have great strength-to-weight ratios, great resistance to rust, and great heat transfer! Because of these qualities, Italian tool makers who need light but strong parts for automobile, aircraft, and consumer electronics can use aluminum die cast components. Being able to make walls that are thin while still being strong lets designers come up with new designs that use less material and make parts that are lighter overall.

Competitive Advantages Over Alternative Manufacturing Methods

Aluminum die casting has a better surface finish and tighter measurement limits than sand casting, so extra grinding processes are often not needed. Metal casting, on the other hand, has the strength and temperature resistance needed for tough tooling uses, unlike injection molding of plastics. Automatic die casting equipment makes it possible to make a lot of things very quickly, which is exactly what Italian makers need for quick response times and flexible production schedules.

Core Reasons Italian Tool Makers Outsource Aluminum Die Casting to China

It was a smart move for Italian makers to team up with Chinese foundries for die casting for a number of reasons that make them more competitive in global markets. Through these agreements, companies can get access to world-class manufacturing facilities that cut down on prices and wait times.

Cost-Effectiveness Without Quality Compromise

Chinese foundries that make metal use economies of scale and improved production methods to offer big price cuts. Chinese makers can offer reasonable prices while keeping high quality standards because they have lower costs for labor and energy and better control of their supply chains. It saves money for Italian tool makers, which they can then put toward research and development and growing their business.

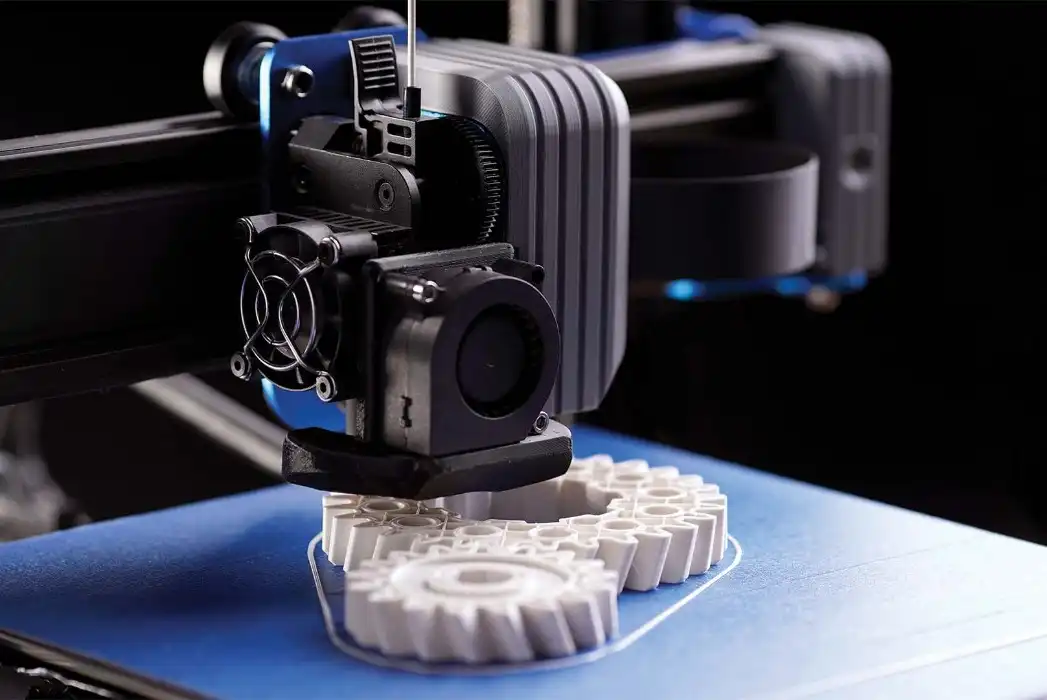

Advanced Manufacturing Technologies and Equipment

Leading die casting factories in China spend a lot of money on new, high-tech tools like high-pressure casting machines, automatic handle systems, and high-tech quality control instruments. Many factories use cutting-edge vacuum casting systems that get rid of trapped air and make parts with great density and mechanical qualities. Smaller Italian foundries often can't afford these technology advances, so working with China is a good idea from a political point of view.

Scalability and Production Flexibility

Chinese makers are very good at handling different production rates, from small batches for prototypes to big production runs. This adaptability is very helpful for Italian tool makers who have to react quickly to changes in the market. Being able to change the amount of output without having to wait a long time makes business processes more flexible and customer service better.

Quality Assurance and Risk Management in Chinese Aluminum Die Casting

For agreements between Italian tool makers and Chinese foundries to work, they need strong quality control systems and thorough plans to reduce risks. Modern factories in China use quality control methods that are among the best in the world and meet or beat international standards.

Comprehensive Quality Control Protocols

The best metal casting factories in China for die casting keep ISO 9001, IATF 16949, and other globally known standards. Modern inspection tools, like coordinate measure machines, X-ray inspection systems, and automatic size checking stations, are used in these places. Statistical process control methods make sure that the quality of each production run is the same, and real-time tracking tools find and fix changes in the process before they affect the quality of the parts.

Defect Prevention and Process Optimization

Chinese foundries fix common casting flaws by using complex methods to improve model design and keep an eye on the whole process. Problems like porosity, cold shuts, and physical warping can be predicted and stopped by advanced modeling tools during the planning process. Mold management systems that control the temperature make sure that the best conditions for casting are met, and automatic degassing methods get rid of hydrogen contamination that can damage the mechanical qualities.

Collaborative Engineering and Design Support

Chinese companies that are on the cutting edge offer full design for manufacturability (DFM) services and work closely with Italian engineering teams to make sure that the designs of parts are best for the casting process. This way of working together cuts down on the time it takes to develop new products, the money it costs to make new tools, and the time it takes to make sure that finished products meet all performance standards. It also keeps production efficient.

Strategic Advantages of Partnering with Chinese Die Casting Manufacturers

Italian tool makers and Chinese foundries work together to do more than just cut costs. They also gain strategic benefits that make both companies more competitive and better able to respond to market needs.

Global Supply Chain Integration

Chinese makers of die casting can easily connect to global supply chains because they have well-established transportation networks, efficient shipping routes, and customs processes that are easy to follow. Many businesses have distribution offices in smart places that cut down on shipping times and costs for customers in Europe. Just-in-time delivery plans are made possible by this system. These schedules reduce the need for stockpiles while keeping output going.

Innovation and Customization Capabilities

Moving On Chinese foundries put a lot of money into research and development, which helps them come up with new ways to solve casting problems. Their technical teams work with Italian partners to create custom metals, special surface processes, and one-of-a-kind parts. With this ability to innovate, Italian tool makers can make their goods stand out and look for new market possibilities that wouldn't be possible with traditional European sources.

Sustainable Manufacturing Practices

Modern Chinese foundries are becoming more and more eco-friendly by using things like melting systems that use less energy, waste heat recovery, and full recycling programs. These efforts to protect the environment are in line with the business responsibility goals of Italian producers and help them follow the stricter environmental rules in European markets.

BOEN Prototype: Your Partner for Advanced Aluminum Casting Solutions

BOEN Prototype specializes in closing the gap between the high quality of Italian design and the production skills of China. Our full range of prototyping and low-volume production services help Italian tool makers develop their products all the way through, from confirming the initial idea to putting the product on the market.

Our metal die casting skills include everything from fast development to making parts that are ready for mass production for use in cars, airplanes, medical devices, and consumer electronics. We know what Italian makers need and can make solutions that meet their high quality standards while lowering costs and shortening lead times.

BOEN's combined approach blends old-fashioned casting methods with cutting-edge additive manufacturing technologies. This makes it possible for mixed production strategies that shorten the time it takes to create new products. Our expert engineering team offers full design support, help with choosing materials, and production optimization services that guarantee project success.

Conclusion

The relationship between Chinese and Italian companies that make metal castings, including die casting, is a big step forward in how companies around the world work together to make things. The combination of Italian design expertise and Chinese manufacturing excellence in this relationship creates value propositions that benefit both parties and serve customers better. Chinese foundries' lower costs, advanced technology, and ability to produce in a variety of ways help Italian companies stay competitive in markets that are becoming more demanding. Concerns about overseas manufacturing have been eased by quality assurance systems and joint engineering methods, which have built trust and confidence in these partnerships. These smart partnerships set Italian tool makers up for long-term success in the global market as global supply lines continue to change.

FAQs

Is it safe to get high-precision machine parts made from aluminum die casting from China?

The best Chinese die casting providers keep up with widely recognized standards like ISO 9001 and IATF 16949. They also use complex quality control procedures to make sure that the parts they make are always precise and consistent, making them ideal for use in important equipment. High-tech measuring tools and statistical process control methods make sure that the dimensions are correct and meet strict European standards.

How do the prices of die casting in China compare to those in Europe?

Chinese die casting has big cost benefits because it uses less labor, materials, and overhead, but the quality is still high. This has long-term benefits, especially for medium to large production runs. It helps Italian companies make the most of their purchasing funds and put money into developing new products and growing their markets.

For unique metal die casting sales in China, how long does the wait time usually take?

Lead times are usually between 4 and 8 weeks, which includes designing, making tools, production, and shipping. Chinese foundries focus on making quick prototypes and being able to adjust production levels to meet the needs of a wide range of clients. For similar projects, they can often turn them around faster than standard European providers.

Partner with BOEN Prototype for Superior Die Casting Solutions

BOEN Prototype is ready to help you with your aluminum casting needs with our full development and small-scale production services. Because we are experts in metal casting, CNC cutting, and quick tooling, we can give Italian companies that want to work with a trusted die casting provider great results.

Our team knows the specific problems that Italian tool makers face and can come up with custom solutions that improve quality, cost, and service. BOEN has the technical know-how and manufacturing excellence you need, whether you need fast development to test an idea or production-ready parts to put a product on the market.

You are welcome to experience the BOEN edge through our full range of consulting services and cheap project offers. Get in touch with us at contact@boenrapid.com to talk about your unique needs and find out how our die casting for sale services can help you compete in global markets.

References

Totten, George E., and MacKenzie, D. Scott. "Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes." CRC Press, 2003.

Kaufman, J. Gilbert, and Rooy, Elwin L. "Aluminum Alloy Castings: Properties, Processes, and Applications." ASM International, 2004.

Campbell, John. "Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design." Butterworth-Heinemann, 2015.

Zhao, Hongda, and Wang, Feng. "Global Manufacturing Networks and Chinese Die Casting Industry Development." International Journal of Manufacturing Technology, 2019.

European Foundry Association. "Quality Standards and Best Practices in International Casting Partnerships." EFA Technical Report, 2020.

Rossi, Marco, and Chen, Wei. "Strategic Partnerships Between European Tool Makers and Asian Manufacturers: A Case Study Analysis." Industrial Engineering Review, 2021.