Middle Eastern builders are turning more and more to Chinese makers for solid aluminum extrusion options because of their high quality, low prices, and advanced manufacturing skills. Chinese aluminum extrusion plants have become the best in the business by providing a wide range of services, from designing unique profiles to making precise parts. With decades of experience and cutting-edge technology, these facilities make extruded aluminum parts that meet international standards and meet the strict building needs of Middle Eastern infrastructure projects.

Understanding Aluminum Extrusion and Its Importance for Middle East Construction

The aluminum extrusion method is one of the most important ways to make things. It uses controlled pressure and heat to shape raw aluminum billets into exact patterns. Because of this advanced production method, makers can get parts that are both lightweight and strong enough to survive the harsh conditions that are common in the Middle East.

What Is Aluminum Extrusion?

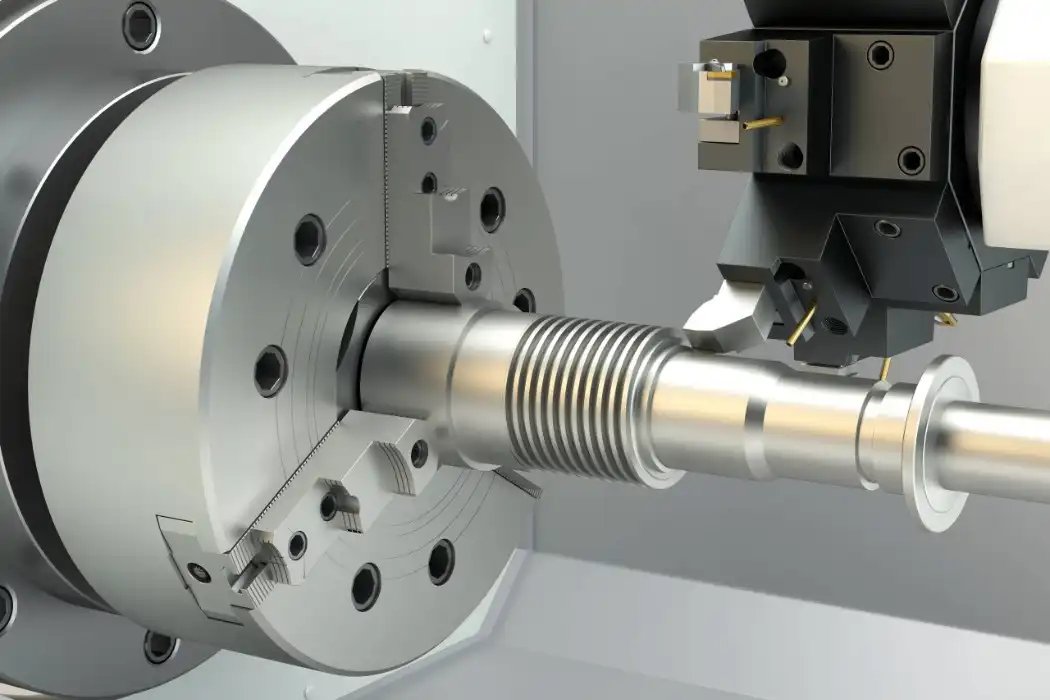

Aluminum extrusion includes heating aluminum billets to around 800 to 900 degrees Fahrenheit and then pushing the weakened metal through tools that have been carefully made for the job. This method makes profiles that are continuous and have stable cross-sectional forms. This lets makers make a wide range of shapes, from simple angles to complex hollow sections. The extrusion method gives designers a lot of freedom while keeping the material's structure during the whole making process.

To make sure the dimensions are correct, modern extrusion plants use computer-controlled systems that keep an eye on temperature, pressure, and the rate at which the material flows. The process starts with preparing the billet, then goes through heating rooms and precision dies. It ends with cooling and finishing steps that make the parts ready to be used right away or processed further.

Key Benefits of Aluminum Extrusion in Construction

There are many benefits to using machined metal parts besides just lowering their weight. These shapes have great strength-to-weight ratios that let builders and engineers make bigger buildings while lowering the total weight of the buildings. Aluminum is naturally resistant to rust, which makes it very useful in towns in the Middle East that are near the sea, where salt air constantly damages building materials.

Another important benefit is design freedom, as aluminum extrusion makes it possible to make complicated shapes that would be hard or impossible to make using conventional casting or cutting techniques. This feature lets builders achieve their own unique ideas for how things should look while still meeting performance and structure standards.

Common Aluminum Extrusion Profiles Used in Building Projects

Several different profile groups are often used in building projects in the Middle East. Each one is best for a certain type of work. For modular building systems, T-slot shapes are great for connecting pieces, and hollow rectangular sections give better structure performance with less material use. For high-load uses, solid curves offer the most strength, and unique forms can be made to fit specific design needs.

One of the most common uses is window frame shapes, which keep rooms comfortable even in harsh conditions by being resistant to weather and good at keeping heat in. Curtain wall systems depend on carefully molded parts that have to stay within very tight limits while holding heavy loads and wind forces.

China Aluminum Extrusion Plants for Middle East Builders

Middle Eastern countries know that Chinese aluminum extrusion plants are good because of their technical know-how, consistent quality, and on-time deliveries. The engineering teams at these companies work with state-of-the-art tools to make parts that meet or go beyond international building standards.

Introduction: Why Choose Chinese Extrusion Plants?

Chinese makers have strong benefits because they have spent a lot of money on modern tools and improving their processes. Many facilities use cutting-edge extrusion tools that can handle big billets while keeping exact control over their dimensions. Their closeness to aluminum smelters lowers the cost of materials, and known shipping paths to ports in the Middle East make processes run smoothly.

Another big benefit is that top Chinese plants have a deep knowledge of the needs, building rules, and quality standards of the Middle Eastern market thanks to years of exporting. This knowledge means that builders can run projects more smoothly and with fewer technology risks.

Leading Manufacturing Facilities and Their Specializations

Weiqiao Aluminum is an expert in building aluminum extrusion, and they are especially good at making curtain wall parts and artistic profiles. Their ISO 9001 license and complex quality control systems make sure that the dimensions are always correct even when making a lot of things. The building has separate lines for anodizing and powder painting, which lets it offer full finishing services.

Zhongwang Holdings mainly makes heavy-duty structure profiles for shipping and building uses. These profiles can hold a lot of weight. As part of their research and development, they offer services like metal creation and profile tuning that help makers reach certain performance goals.

Guangdong Fenglu Aluminum has several factories that focus on making precise extrusions for use in architecture. Their expert team works closely with partners in the Middle East to create unique solutions that deal with the temperature problems and building code standards in that area.

Jiangyin Haida Rubber and Plastic specializes in systems that blend aluminum extrusions with closing parts to make them more weatherproof. This feature is especially useful for projects in the Middle East, where dust and temperature changes are constant problems.

Leading sites also have specialized makers that focus on certain types of profiles or finishing methods. All together, these businesses have thousands of tons of extrusion press capacity and a wide range of engineering support services.

Comparative Analysis of These Plants

There is a wide range in the production ability of the top sites. The biggest ones can handle thousands of tons of materials every month. Quality control systems usually include checking the materials that come in, keeping an eye on the work that's being done, and checking the end sizes with coordinate measuring machines and other accurate tools.

Most of the time, lead times are between two and six weeks, but this depends on how complicated the profile is and how many orders are placed. Most facilities offer faster services for immediate needs. Custom manufacturing creation usually takes longer, but it gives you access to unique profile designs that help you stand out from the competition.

How to Select the Right Aluminum Extrusion Supplier for Your Project?

To choose a good source, you need to carefully consider a lot of different things that affect how the job turns out. Smart buying teams come up with detailed criteria that balance expert skills with business needs while also making sure that the partnership will work in the long run.

Understanding Your Project Requirements and Constraints

Different sites improve their processes for different order sizes, which has a big effect on how suppliers are chosen. The complexity of the profile affects the cost of tools and wait times, while the specs of the metal affect where to get materials and how they are processed. When there are limited funds, it's important to think about how much it will cost to move things and how the value of the currency might change.

To meet delivery dates, work schedules and shipping plans must be carefully coordinated. When builders plan their projects, they should think about how seasonal demand changes and any area transportation issues that might make delivery less reliable during busy building times.

Core Metrics for Supplier Evaluation

Quality licenses are very important for giving you peace of mind, and ISO 9001 is the level that most projects should meet at the very least. Other certifications, like ISO 14001 for environmental management and OHSAS 18001 for safety standards, show that the business is truly excellent in every way.

The evaluation of manufacturing technology for aluminum extrusion should include the number of extrusion presses that can be used, the tools that can be used, and the availability of finishing equipment. When projects need custom metals or specific performance qualities, research and development skills become very important.

Weighing Cost vs Quality vs Lead Time

When you do a cost-effectiveness study, you need to look at more than just the price per kilogram. You also need to look at the costs of tools, finishing, and shipping. Dimensional accuracy, surface finish standards, and the stability of mechanical properties should all be taken into account when thinking about quality.

Lead time freedom lets builders make changes to the project plan while keeping the building process moving forward. Suppliers who offer more than one shipping choice and inventory management services add value by making the buying process easier.

Final Decision-Making Tips for Middle East Builders

For relationships to work, there must be clear rules for how to communicate and set high standards from the start of the job. Builders should give priority to sellers who respond quickly to technical questions and are willing to offer application help while the project is being carried out.

Strategies for lowering risks should include finding a backup provider and making sure the quality of the work is checked so that it works the same way on all orders. Regular reviews of performance help keep service levels steady and find ways to make the process better.

Advantages of Partnering with Chinese Aluminum Extrusion Manufacturers for Middle East Projects

Chinese aluminum extrusion makers offer great value because they have advanced manufacturing skills, competitive economies, and a well-established export infrastructure. Because of these benefits, makers in the Middle East can get world-class parts while keeping project costs low and delivery times reliable.

Overview of Common Market Solutions for Aluminum Extrusion

Local providers in the Middle East, European makers, and North American sites are some other choices for buying. Local providers make transportation easier, but they might not have the right skills or ability for big tasks. European choices are closer, which is a plus, but they usually cost more, which changes the economics of the project.

Other ways to make things, like forging, precision machining, or casting aluminum, might work in some situations, but they can't usually compare to extrusion when it comes to cost and design freedom for building parts.

Why Chinese Extrusion Plants Often Lead in Value and Innovation?

Leading Chinese facilities put a lot of money into research projects that make new alloys with specific formulas for different uses. This is one of the main things that sets them apart. Customization options go beyond just changing the size; they also include built-in features that make building easier and boost performance.

Reliability and professional skill are shown by the fact that many building projects in the Middle East have been completed successfully. Many sites have specialized teams that know the local building codes and requirements. This makes project completion easier and lowers technical risks.

Key Considerations When Engaging Chinese Providers

To get the best delivery performance for aluminum extrusion, logistics management needs to make sure that the shipping plans and production schedules work together. Most well-known suppliers have working ties with international freight forwarders who specialize in paths through the Middle East. This makes sure that transportation and customs clearance go smoothly.

Understanding different cultures and using the same business practices can help people get along at work. Leading providers usually have expert teams that speak English and follow business practices that are in line with international standards. This makes it easier for people to communicate and makes the process simpler.

Why These Suppliers Are Preferred by Regional Builders?

To build trust, you need to provide regular delivery and expert help that goes beyond just fulfilling orders. Certification makes sure that parts meet foreign standards, and full after-sales help takes care of any problems that come up during installation or during the product's working life.

Focusing on long-term relationships helps providers learn a lot about what customers want and how the market is changing. This lets them make strategic ideas for ways to improve processes and cut costs.

Aluminum Extrusion Process Optimization and Sustainability for Industrial Buyers

Advanced optimization methods are used in modern aluminum extrusion processes to improve quality while lowering their effect on the environment. These changes help industry buyers because the parts work better and are in line with green goals, which are becoming more important in buying choices.

Insight into the Aluminum Extrusion Process Steps

Carefully choosing the right material and controlling the heat during billet preparation are important for getting the best flow properties during extrusion. Heating systems carefully control the temperature to make sure that the qualities of materials are the same while using as little energy as possible. To get the right dimensions and surface quality, you have to carefully tweak extrusion factors like press speed and die temperature.

When cooling something, you have to balance the need for efficiency with metallurgy concerns that affect the end mechanical qualities. Finishing steps include cutting, grinding, and surface cleaning, which get parts ready to be used right away and add value by making them look better and work better.

Performance Optimization Techniques Used by Top Plants

Tolerances in high precision extrusion are measured in hundredths of millimeters and are reached with the help of modern die design and process control systems. Real-time tracking systems are used in tight spec manufacturing methods to find and fix differences before they affect the quality of the result.

Specialized metal formulas are used in advanced applications to get the best strength, rust protection, or heating qualities for those uses. Design optimization services help clients reach their performance goals while reducing the amount of material used and the cost of processing.

Sustainability: Recycling and Environmental Benefits

When compared to making aluminum from scratch, recycling methods for aluminum extrusion use up to 95% less energy while keeping all of the material's qualities. Leading sites use recycled materials and make sure that quality standards are always met to meet building code requirements.

Some of the things that green buildings do are help you earn LEED points by using salvaged materials and materials from nearby. Long-term cost saves come from the need for less upkeep and longer service life that metal parts offer in harsh environments.

BOEN Prototype: Your Partner for Precision Aluminum Prototyping and Manufacturing

Here at BOEN Prototype, we know how important precise metal parts are in today's industry and building settings. Our full-scale development and low-volume manufacturing services fill the gap between design ideas and full-scale production. This lets builders and makers in the Middle East test designs and improve performance before committing to large-scale orders.

Company Overview

Rapid development and low-volume production are what BOEN Prototype does best in a number of fields, such as automobiles, aircraft, medical devices, and consumer electronics. We are experts at making metal parts that need to be fabricated precisely and with tight tolerances. We work with companies that need quick feedback cycles and variable manufacturing solutions as a trusted development partner.

Product and Service Offerings

We can handle aluminum using CNC machining for complicated shapes, die casting for large quantities, and precision manufacturing services that work with traditional extrusion methods. We use modern 3D printing technologies to make quick prototypes and offer a full range of finishing services, such as anodizing and sealing.

Value-added services include design advice, help choosing materials, and building help that shortens the time it takes to develop a project. Our engineering team works closely with clients to make sure that designs are optimized for production while still meeting performance and cost goals.

Commitment to Quality and Client Satisfaction

Quality assurance routines include thorough checking methods and systems for tracking materials that make sure all packages have the same level of performance. Our licenses and respect to foreign standards give projects that need to be sure they are following building rules and performance standards peace of mind.

Client reviews always talk about how quick we are, how knowledgeable we are in technology, and how we can finish complicated projects on time. We have long-term relationships with customers in a wide range of businesses who depend on our knowledge to help them build key parts and test prototypes.

How to Initiate Collaboration?

Our efficient question process starts with expert talks that make sure we understand what you need and figure out the best way to make it. Sample development services let you check how well something works, and full quotes make price clear so you can make an informed choice. Procedures for order completion make sure that the change from developing prototypes to delivering finished goods goes smoothly.

Conclusion

Chinese aluminum extrusion plants are a great deal for builders in the Middle East because they can make complex products at low costs and offer full technical support. With quality approvals, shipping experience, and well-established transportation networks, we can make sure that building projects with strict requirements can get the parts they need. For a business to be successful, it needs to carefully evaluate its suppliers, taking into account both their technical and business skills while also focusing on building long-term partnerships. Modern methods of extrusion make better parts that meet international standards and help reach goals for sustainability and cost-effectiveness.

FAQs

In general, how long does it take for custom aluminum extrusion orders to get from China to the Middle East?

Production times are usually between 2 and 6 weeks, but they rely on how complicated the profile is and how many tools are needed. It takes an extra 7 to 14 days to ship internationally. In big Middle Eastern ports, clearing customs usually takes three to five work days. For jobs that need to be done quickly, there are expedited services available, but the time it takes to create tools cannot be sped up below the minimum technical requirements.

How does steel extrusion and aluminum extrusion compare in terms of cost and how long they last for building projects?

When compared to steel, aluminum extrusion is more resistant to rust and lighter, which lowers structure loads and upkeep costs over the lifetime of a building. Even though the initial cost of the material may be higher, aluminum's ability to be recycled and long service life often make the total cost of ownership cheaper. Steel has a higher final strength, but it needs protective coats in the Middle East, where metals tend to rust.

Can Chinese aluminum extrusion plants handle orders for prototypes or small amounts?

Most factories that have been around for a while are happy to take small orders, especially if they lead to bigger production runs. A lot of sellers have open minimum order amounts and services for developing samples that help with the development of prototypes. Tooling costs are usually spread out over a number of orders, which means that small amounts can be made cheaply for specific uses or to test the market.

Partner with BOEN Prototype for Your Aluminum Manufacturing Needs

BOEN Prototype is ready to help you build your metal parts with our full range of prototype and production services. We have experience in a lot of different fields and uses, which lets us give you precise answers that meet your strictest needs. Our skilled professionals can help you with fast development, low-volume production, or design improvement. They have the technical knowledge and industrial freedom you need.

Our relationships with aluminum extrusion manufacturers and our own production skills give us access to the newest technologies and ways of making things. We know the specific problems that builders and makers in the Middle East face and can help them find answers that meet regional needs while still meeting international quality standards. Get in touch with us at contact@boenrapid.com to talk about your unique needs and find out how our experience making metal products can help your project succeed faster.

References

International Aluminum Institute. "Global Aluminum Extrusion Market Analysis and Regional Construction Applications." Annual Industry Report, 2023.

Middle East Construction Review. "Aluminum Building Systems: Performance Standards and Supplier Evaluation Criteria for Regional Projects." Technical Bulletin, Volume 45, 2023.

Chinese Nonferrous Metals Industry Association. "Export Performance and Quality Standards of Chinese Aluminum Extrusion Facilities." Manufacturing Excellence Study, 2023.

Construction Materials Research Institute. "Corrosion Resistance and Durability Testing of Aluminum Extrusions in Middle Eastern Climate Conditions." Technical Research Paper, 2023.

Building Standards Council. "Aluminum Extrusion Specifications and Compliance Requirements for International Construction Projects." Regulatory Guidelines, 2023.

Procurement Management Association. "Supplier Selection Criteria and Risk Assessment for International Aluminum Sourcing." Best Practices Manual, 2023.