Can 3D Printing Be Used for End-Use Mechanical Parts?

In reality, 3D printing has changed contemporary production in several fields by making it possible to make mechanical components that can be used right away. Advanced additive manufacturing technologies are being used to make practical components that fulfill strict mechanical standards for use in industry, cars, planes, and medicine. Modern 3D printing techniques make parts with complicated shapes, great strength-to-weight ratios, and material properties that are similar to or better than those of parts made in the traditional way. This makes them good for important mechanical uses.

Understanding 3D Printing for End-Use Mechanical Parts

Modern additive manufacturing is a big change from subtractive approaches to layer-by-layer assembly. This gives designers more freedom and lets them combine different functions in ways that were never possible before. This method generates three-dimensional objects straight from digital data. This implies that designing mechanical parts doesn't have to be restricted by expensive machines or hard-to-use machining settings.

Core 3D Printing Technologies for Mechanical Components

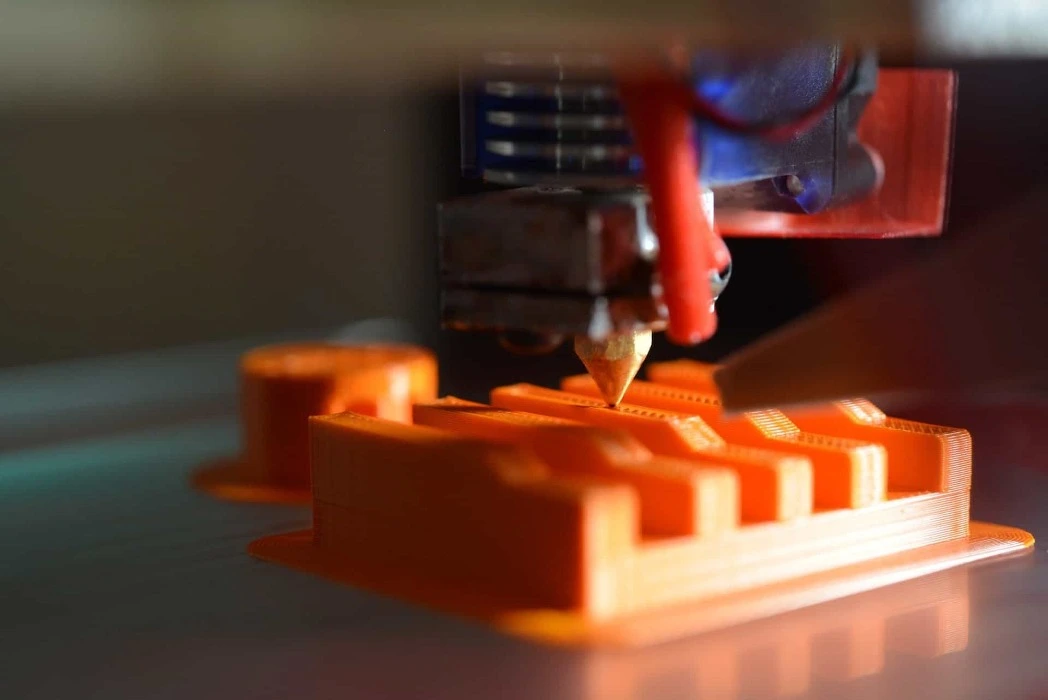

There are a lot of different technologies in additive manufacturing, and each one is made for a certain mechanical purpose. In fused deposition modeling (FDM), thermoplastic filaments are heated and pushed through precise nozzles. This produces strong components that are good for low-stress mechanical uses and functional testing. Stereolithography (SLA) uses ultraviolet lasers to turn liquid photopolymers into solid structures. This gives them a very smooth surface and precise dimensions, which are both important for precision mechanical parts.

Selective Laser Sintering (SLS) is a powder-based 3D printing method that uses laser energy to fuse polymer particles. This produces products with better mechanical properties and no need for a support structure. Direct Metal Laser Sintering (DMLS) uses the notion of 3D printing to make entirely solid metal parts that are equally as durable and last as long as those manufactured with traditional methods.

Evolution from Prototyping to Production

Rapid prototyping to end-use manufacturing is a process that represents decades of advances in material science and technology. The groundwork for a breakthrough manufacturing paradigm was established by Chuck Hull's 1984 patent on stereolithography. There are now many techniques to turn computer drawings into tangible items thanks to Carl Deckard's later creation of SLS and Scott Crump's FDM.

Through the 1990s, commercial adoption sped up as industries realized how it might shorten time-to-market and allow for design breakthroughs that were not achievable with traditional approaches. The sophisticated systems of today create mechanical components that fulfill vital roles in demanding applications, backed by stringent material certification and quality control procedures.

Evaluating 3D Printing Technologies for Mechanical Parts Production

Selecting appropriate additive manufacturing technologies requires careful analysis of material properties, production volumes, and performance requirements. Each technology offers distinct advantages and limitations that influence suitability for specific mechanical applications.

Material Performance and Selection Criteria

High-performance polymers like PEEK, PEI, and carbon-fiber-reinforced composites provide exceptional mechanical properties suitable for demanding applications. These materials exhibit excellent chemical resistance, dimensional stability, and strength characteristics that enable direct replacement of traditionally manufactured components. Metal options including titanium alloys, stainless steel, and aluminum deliver superior strength-to-weight ratios essential for aerospace and automotive applications.

Material selection directly impacts part performance in 3D printing, with factors including operating temperature, chemical exposure, and mechanical stress determining optimal choices. Advanced polymer formulations now achieve tensile strengths exceeding 100 MPa in 3D printing, while metal components can match or surpass wrought material properties through optimized 3D printing processing parameters.

Technology Benefits and Limitations

For mechanical components, additive manufacturing offers substantial operational benefits in addition to design flexibility. Design optimization cycles may be measured in days rather than months because to rapid iteration capabilities, and low-volume manufacturing becomes economically feasible when tooling expenses are eliminated. Topology-optimized structures, integrated assemblies, and intricate interior geometries are examples of design opportunities exclusive to additive techniques.

However, while assessing the use of technology, several restrictions must be recognized. Layer adhesion qualities may affect mechanical properties in certain orientations, and build volume restrictions may necessitate part segmentation or assembly activities. For high-volume applications, material prices are usually higher than those of conventional manufacturing, and post-processing needs for surface finishing or dimensional accuracy complicate production processes.

Application Scenarios and Case Studies of End-Use Mechanical Parts by 3D Printing

Real-world implementations demonstrate the maturity and reliability of additive manufacturing for critical mechanical components across diverse industries. These applications showcase how design optimization and material selection contribute to parts that withstand operational stresses while delivering measurable performance improvements.

Automotive Industry Applications

Manufacturers of electric vehicles use 3D printing to create unique brackets, heat management systems, and lightweight structural parts. Battery cooling manifolds made using SLS technology have intricate interior geometries that are not achievable with traditional production, increasing thermal efficiency while lowering weight. Powertrain component functional prototypes speed up development timelines for competitive market launch by enabling quick validation of design ideas.

The flexibility of additive manufacturing to combine many functionalities into a single part is advantageous for interior components. Electronic housings, ventilation ducts, and dashboard assemblies show how consolidation preserves structural integrity while lowering assembly complexity. The manufacturing flexibility necessary for contemporary vehicle production is supported by custom tooling and fixtures made on demand.

Aerospace and Defense Implementations

One of the most demanding industries for 3D printing mechanical components is aerospace, where operating efficiency is directly impacted by weight reduction and performance improvement. When compared to their conventionally manufactured counterparts, titanium alloy components made using DMLS technology achieve weight savings of over 40% while still meeting structural requirements.

Polymer and composite materials are used by drone makers for electrical enclosures, propeller assembly, and lightweight structural components. The dependability of additive manufacturing for safety-critical applications is shown by these components, which go through extensive testing to verify performance under operating conditions. Specialized needs are supported by small-batch production capabilities without the financial consequences of typical manufacturing setup expenditures.

Medical Device Innovations

Production of surgical tools and medical equipment customized to each patient's anatomical needs is made possible by biocompatible materials. Orthopedic implants made using metal additive manufacturing preserve the mechanical strength required for load-bearing applications while achieving the ideal porosity for bone integration.

Custom apparatus and surgical guide templates serve as examples of how additive manufacturing shortens development times while improving procedural accuracy. These uses demonstrate how the technology may connect digital design and physical execution, allowing for mass customisation that was previously unattainable using traditional techniques.

Key Considerations for B2B Procurement of 3D Printed Mechanical Parts

Successful integration of additive manufacturing requires strategic procurement approaches that address technical specifications, quality assurance, and supplier capabilities. These considerations ensure optimal technology selection and reliable part performance throughout product lifecycles.

Technology and Supplier Selection

A thorough examination of the component specifications, including dimensional tolerances, material characteristics, and production quantities, is the first step in selecting the best 3D printing technology. In addition to offering clear quality documentation and process control procedures, suppliers must exhibit capabilities that meet the requirements of particular applications.

Equipment capabilities, material certifications, and post-processing facilities necessary to achieve needed part attributes should all be included in the evaluation criteria. While intellectual property protection mechanisms guarantee design secrecy throughout manufacturing processes, geographic proximity may have an impact on lead times and shipping costs.

Quality Assurance and Standards Compliance

Strict quality control procedures are necessary for end-use mechanical components to guarantee reliable performance and legal compliance. Procedures for material testing, functional validation, and dimensional inspection must adhere to industry standards and application-specific specifications.

Material certificates, process specifications, and inspection reports proving adherence to relevant standards are among the documentation needs for 3D printing. When performance concerns occur, traceability systems for 3D printing facilitate quality inquiry and the execution of remedial action, enabling continuous improvement activities that are crucial for enduring supplier relationships.

Environmental and Sustainability Considerations

Through material economy and local production capabilities that lower transportation needs, additive manufacturing provides intrinsic sustainability benefits. On-demand manufacturing removes the risk of obsolescence and inventory carrying costs, while powder recycling technologies reduce material waste.

Environmental practices of suppliers, such as energy use, waste disposal, and recycling initiatives, help to match business sustainability goals with procurement choices. Considerations for life cycle analysis include the source of materials, the energy needed for manufacturing, and solutions for recycling or end-of-life disposal that promote the circular economy.

BOEN Prototype: Your Partner for Advanced 3D Printing Solutions

BOEN Prototype stands at the forefront of additive manufacturing innovation, delivering comprehensive solutions that transform digital designs into high-performance mechanical components. Our extensive experience across automotive, aerospace, medical, and industrial sectors provides deep understanding of application-specific requirements and quality standards essential for end-use parts.

Comprehensive Technology Portfolio

Our advanced manufacturing capabilities encompass the full spectrum of 3D printing technologies, enabling optimal process selection for diverse mechanical applications. SLA systems deliver exceptional surface finish and dimensional accuracy for precision components, while SLS technology produces robust parts with excellent mechanical properties suitable for functional applications.

Metal additive manufacturing capabilities include stainless steel, titanium alloys, and aluminum processing that meets demanding performance requirements. Our integrated approach combines additive manufacturing with traditional processes including CNC machining, injection molding, and finishing operations to deliver complete solutions tailored to specific project needs.

Tailored Solutions for B2B Clients

We provide specialized consultancy services that direct technology selection and design optimization since we recognize that every application has different obstacles. Throughout the development process, our engineering team works in tandem with customers, providing design knowledge for additive manufacturing that optimizes performance while reducing production complexity.

Prototype development verifies design ideas prior to full-scale production commitment, while material selection assistance guarantees optimum property matching for particular 3D printing applications. The performance of 3D printed parts and regulatory compliance are guaranteed by quality assurance procedures that are in line with customer requirements and industry standards.

Process Transparency and Support

We preserve open lines of contact with customers throughout manufacturing cycles, from the first consultation to delivery and post-purchase assistance. Real-time project monitoring and high-quality documentation are made possible by digital workflow integration, and flexible scheduling may handle pressing needs that are typical in cutthroat marketplaces.

Our dedication to ongoing development motivates us to invest in cutting-edge equipment and streamline procedures, which enhances all of our customer connections. Technical support goes beyond delivery to include technical help and application advise to optimize the value of adopting additive manufacturing.

Conclusion

The evolution of 3D printing from rapid prototyping to end-use mechanical part production represents a fundamental transformation in manufacturing capabilities. Advanced additive technologies now deliver components that meet stringent mechanical requirements while enabling design innovations impossible through traditional methods. Success requires careful evaluation of technology options, material selection, and supplier capabilities to ensure optimal performance and quality compliance. As the technology continues advancing, 3D printing will increasingly become the preferred choice for mechanical parts requiring design flexibility, rapid delivery, and exceptional performance characteristics.

FAQ

1. How does the mechanical strength of 3D printed parts compare to traditional manufacturing?

Modern 3D printing technologies produce parts that match or exceed the mechanical properties of traditionally manufactured components when appropriate materials and processes are selected. Metal additive manufacturing achieves densities approaching 100% of wrought materials, while advanced polymers provide strength-to-weight ratios suitable for demanding applications. Proper design orientation and post-processing treatments optimize mechanical performance for specific loading conditions.

2. What are typical lead times for 3D printed mechanical parts?

Lead times for additive manufacturing typically range from days to weeks depending on part complexity, material selection, and post-processing requirements. Simple polymer components can often be completed within 24-48 hours, while complex metal parts requiring extensive finishing may need several weeks. The elimination of tooling requirements significantly reduces lead times compared to traditional manufacturing methods, particularly for low-volume applications.

3. How do you ensure quality control for end-use mechanical parts?

Quality assurance encompasses multiple verification stages including material certification, process parameter validation, dimensional inspection, and functional testing. Advanced measurement systems verify dimensional accuracy and surface finish characteristics, while material testing confirms mechanical properties meet specifications. Documentation packages provide complete traceability from raw materials through final inspection, ensuring compliance with relevant standards and client requirements.

4. What factors influence the cost of 3D printed mechanical parts?

Cost considerations include material selection, part complexity, build time, post-processing requirements, and production volume. Material costs vary significantly between polymer and metal options, while part geometry influences build efficiency and support material requirements. Post-processing operations including machining, surface treatments, and finishing add to total costs but enable achievement of specific performance characteristics essential for mechanical applications.

Start Optimizing Your Mechanical Part Procurement with Advanced 3D Printing Solutions

Ready to transform your mechanical part procurement strategy through advanced additive manufacturing? BOEN Prototype delivers comprehensive 3D printing solutions that combine cutting-edge technology with decades of manufacturing expertise. Our experienced team provides customized consultation services, helping you select optimal technologies and materials for your specific applications while ensuring quality compliance and competitive pricing.

Whether you need rapid prototypes, low-volume production, or complex geometries impossible through traditional manufacturing, our integrated approach delivers results that exceed expectations. Contact our specialists at contact@boenrapid.com to discuss your requirements and discover how our 3D printing manufacturer capabilities can enhance your product development and supply chain flexibility. Let us demonstrate why leading companies across automotive, aerospace, medical, and industrial sectors trust BOEN Prototype for their most critical mechanical component needs.

References

1. Gibson, I., Rosen, D., & Stucker, B. (2021). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer International Publishing.

2. Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T., & Hui, D. (2018). Additive manufacturing technologies for structural applications: A comprehensive review. Composites Part B: Engineering, 162, 218-252.

3. DebRoy, T., Wei, H. L., Zuback, J. S., Mukherjee, T., Elmer, J. W., Milewski, J. O., & Zhang, W. (2018). Additive manufacturing of metallic components–process, structure and properties. Progress in Materials Science, 92, 112-224.

4. Wohlers, T., Campbell, I., Diegel, O., Huff, R., & Kowen, J. (2022). Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry. Wohlers Associates.

5. Tofail, S. A., Koumoulos, E. P., Bandyopadhyay, A., Bose, S., O'Donoghue, L., & Charitidis, C. (2018). Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Materials Today, 21(1), 22-37.

6. Salmi, M., Paloheimo, K. S., Tuomi, J., Wolff, J., & Mäkitie, A. (2013). Accuracy of medical models made by additive manufacturing. Journal of Cranio-Maxillofacial Surgery, 41(7), 603-609.

How Can We Help?

Your Trusted Partner in Rapid Manufacturing.